Welding and shaping integrated method for circular titanium target material and back plate

A titanium target and round technology, which is applied in the field of welding and shaping integration of round titanium targets and backing plates, can solve the problems of reduced shaping qualification rate, cumbersome operation, energy consumption and other problems, and avoid shaping operations, The effect of increasing the contact area, improving the welding pass rate and shaping pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

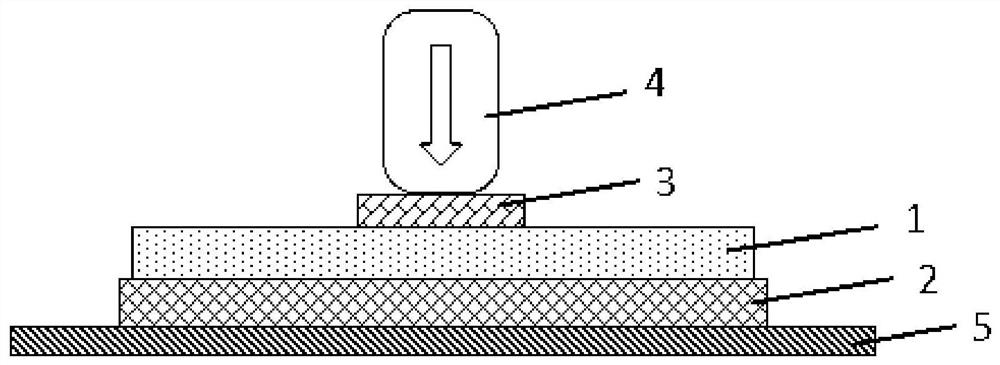

[0066] This embodiment provides an integrated method for welding and shaping a circular titanium target and a back plate. The diameter of the circular titanium target is 300 mm. The integrated method includes the following steps:

[0067] (1) First heat the round titanium target 1 with a purity of 99.999% to 235°C and keep it warm, then place the solder on the welding surface of the round titanium target 1 to melt the solder, and then use The lead-free steel brush infiltrates the welding surface of the circular titanium target 1 maintained at 235°C and the molten solder;

[0068] First heat the CuZn alloy backplane 2 to 235°C and keep it warm, then place the solder on the welding surface of the CuZn alloy backplane 2 to melt the solder, and then use a lead-free steel brush to keep the temperature at Wetting the welding surface of the CuZn alloy backplane 2 and the molten solder at 235°C, and then ultrasonically treating the welding surface of the CuZn alloy backplane 2 and the...

Embodiment 2

[0074] This embodiment provides an integrated method for welding and shaping a circular titanium target and a back plate. The diameter of the circular titanium target is 300 mm. The integrated method includes the following steps:

[0075] (1) First heat the round titanium target 1 with a purity of 99.995% to 220°C and keep it warm, then place the solder on the welding surface of the round titanium target 1 to melt the solder, and then use The lead-free steel brush infiltrates the welding surface of the circular titanium target 1 maintained at 220°C and the molten solder;

[0076] First heat the CuCr alloy backplane 2 to 220°C and keep it warm, then place the solder on the welding surface of the CuCr alloy backplane 2 to melt the solder, and then use a lead-free steel brush to keep the temperature at Wetting the welding surface of the CuCr alloy backplane 2 and the molten solder at 220°C, and then ultrasonically treating the welding surface of the CuCr alloy backplane 2 and the...

Embodiment 3

[0082] This embodiment provides an integrated method for welding and shaping a circular titanium target and a back plate. The diameter of the circular titanium target is 300 mm. The integrated method includes the following steps:

[0083] (1) First heat the round titanium target 1 with a purity of 99.999% to 250°C and keep it warm, then place the solder on the welding surface of the round titanium target 1 to melt the solder, and then use The lead-free steel brush infiltrates the welding surface of the circular titanium target 1 maintained at 250°C and the molten solder;

[0084] First heat the CuZn alloy backplane 2 to 250°C and keep it warm, then place the solder on the welding surface of the CuZn alloy backplane 2 to melt the solder, and then use a lead-free steel brush to keep the temperature at Wetting the welding surface of the CuZn alloy backplane 2 and the molten solder at 250°C, and then ultrasonically treating the welding surface of the CuZn alloy backplane 2 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com