A fiber coupler for high-efficiency coupling of high-power pump light

A fiber optic coupler and pumping optical fiber technology, applied in the field of fiber optic couplers, can solve the problems of difficult fiber coupling, low optical power into the fiber, and low pumping efficiency, and achieve low difficulty in processing and adjustment, high coupling efficiency, The effect of high fiber insertion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

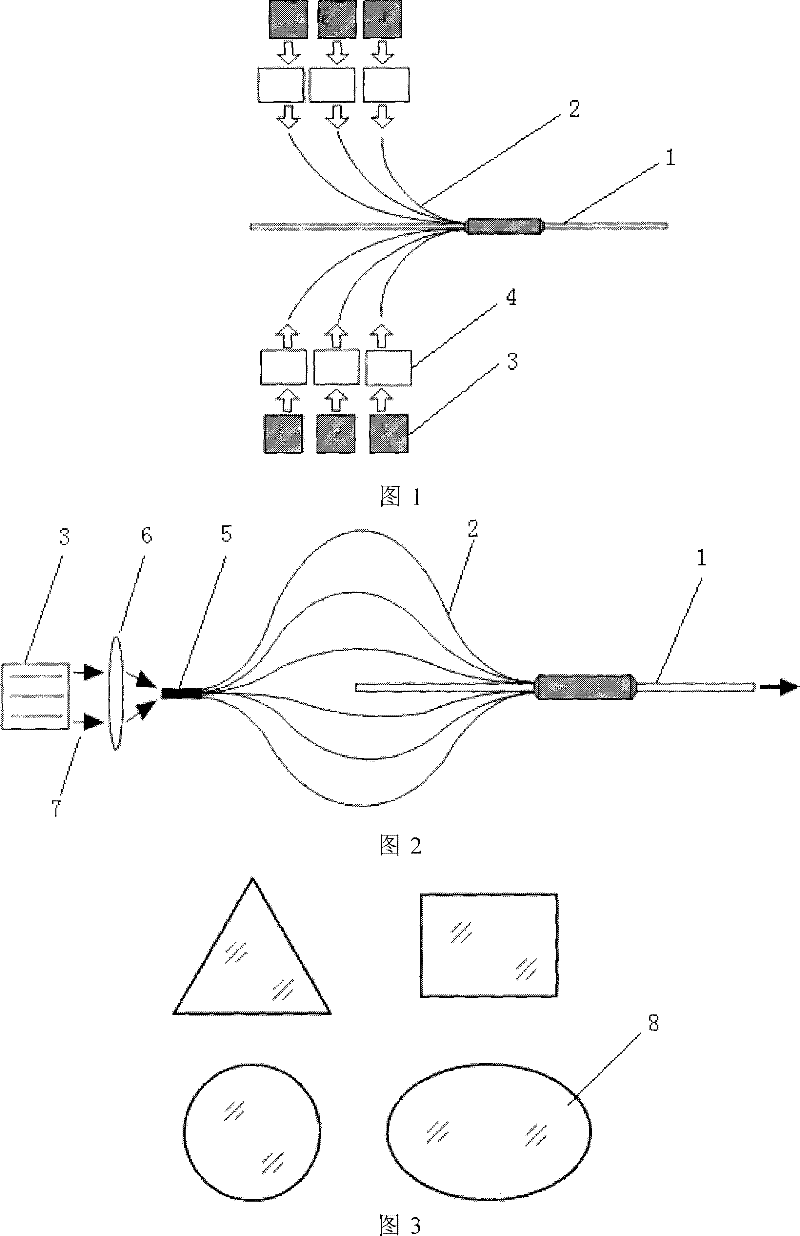

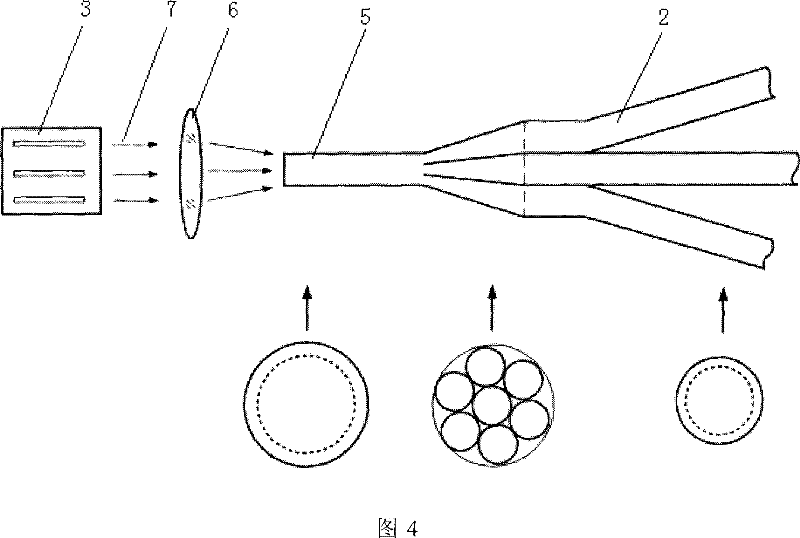

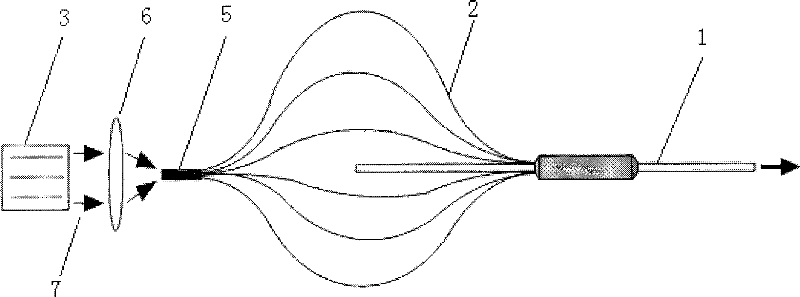

[0015] The detailed structure of the present invention will be described below in conjunction with the accompanying drawings.

[0016] The structure of the first embodiment of the present invention is as figure 2 As shown, in the application of using a fiber coupler to pump a fiber laser, the pump light (7) emitted by the laser pump source (3) directly enters the fiber input of the fiber coupler through the action of the optical coupling component (6). end (5), and then through the multi-branch pumping fiber (2) transmission respectively, the output end of the pumping fiber (2) is injected into the main fiber (1) of the fiber coupler, and the pumping light (7) is in The inside of the main fiber (1) is transmitted along a certain direction, and finally a pumping beam with high beam quality is obtained at one end of the main fiber (1), which is used to pump the fiber laser.

[0017] A fiber coupler for high-efficiency coupling of high-power pump light proposed by the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com