Hazardous gas leakage detection inspection robot and inspection method

An inspection robot and leak detection technology, applied in the field of inspection robots, can solve the problems of high degree and concentration of gas leakage, weak environmental adaptability of control methods, difficult maintenance, etc., and achieves low computing power and power consumption requirements. The effect of normal operation ability and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

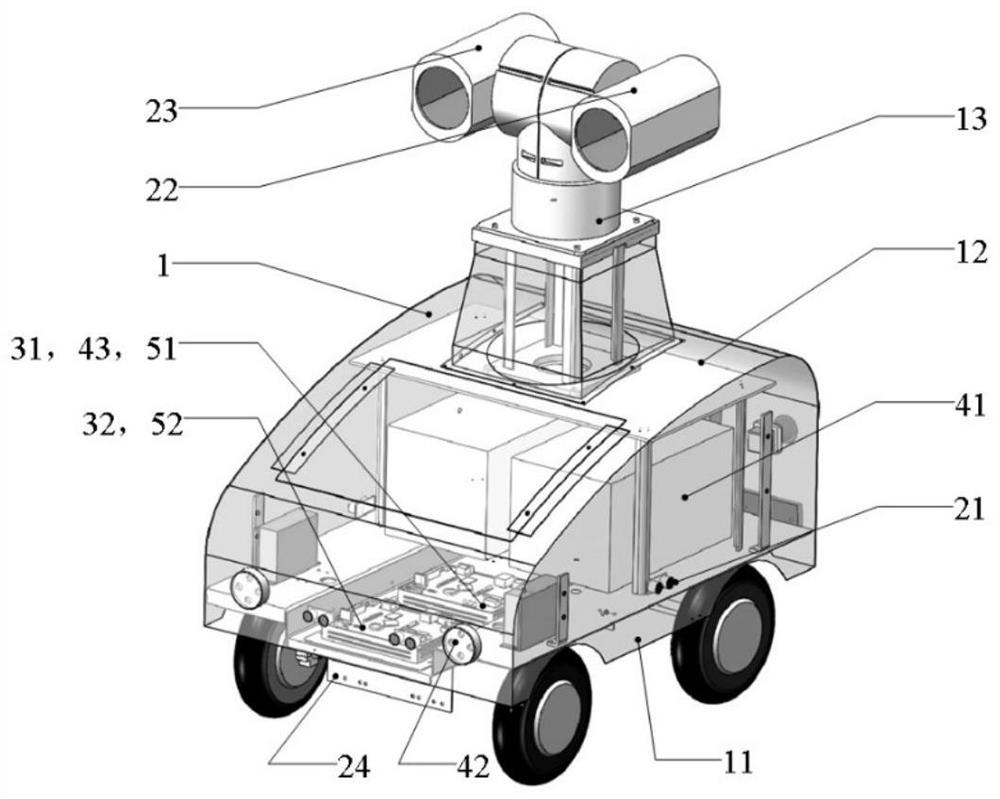

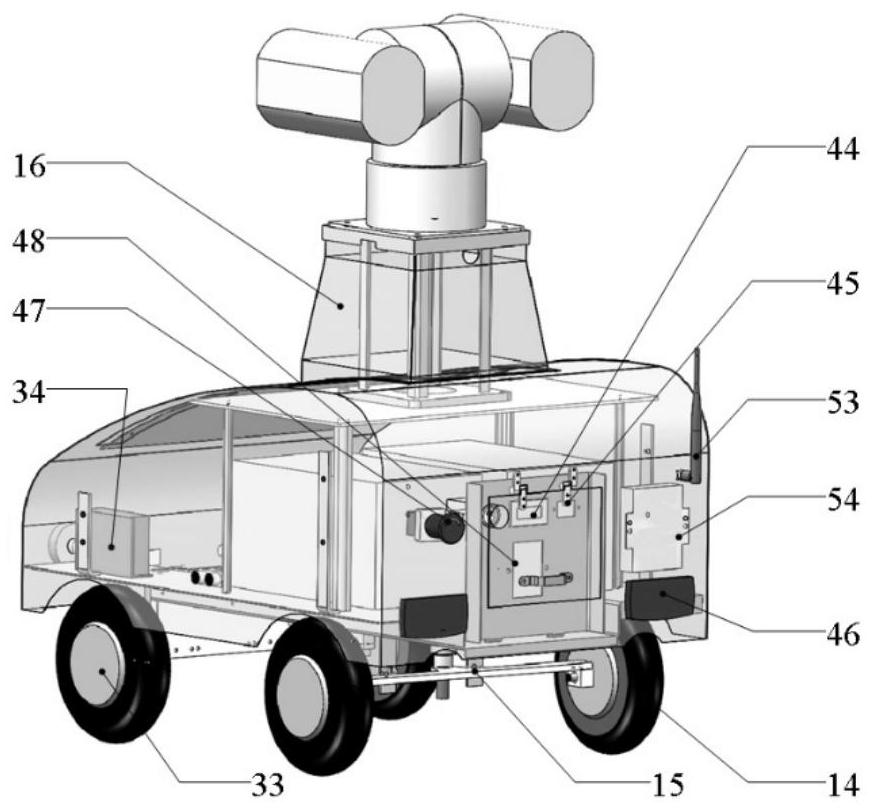

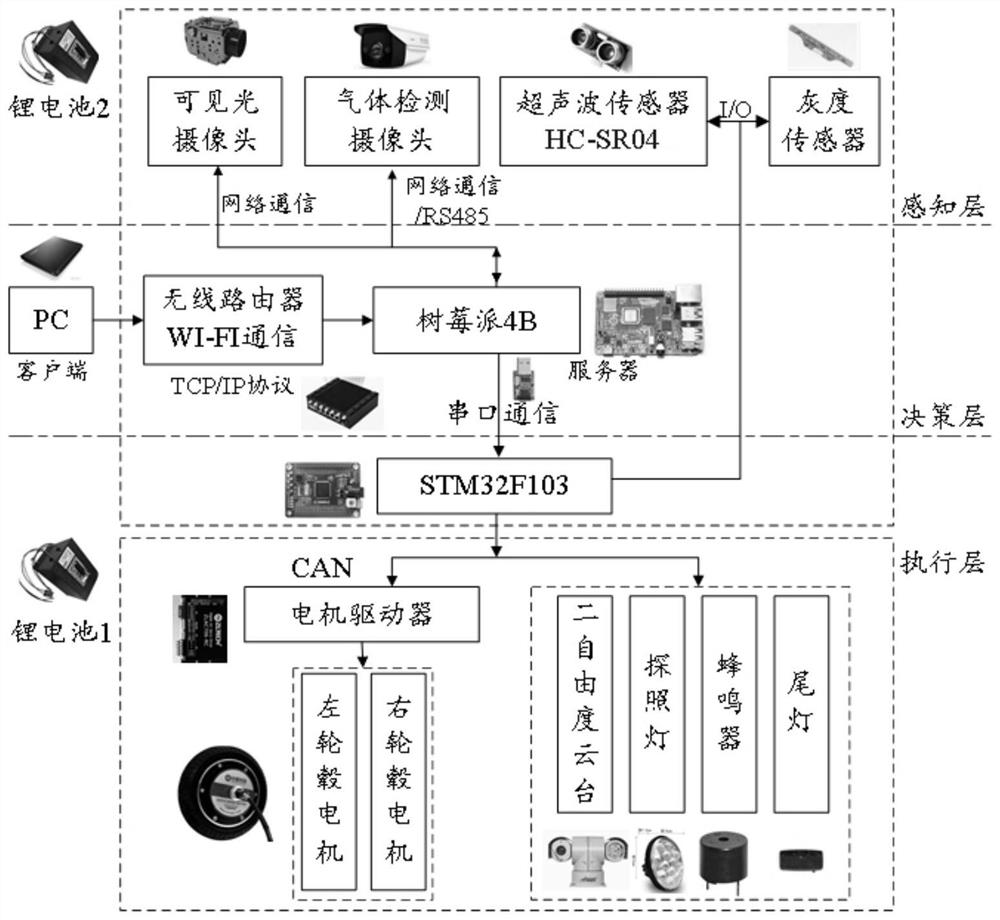

[0059] Embodiment 1: Embodiment 1 of the present invention provides a hazardous gas detection inspection robot system, which mainly includes a robot mechanical system, a sensor system, a control system, an electrical system and a communication system.

[0060] The mechanical system includes a chassis structure 11 , a casing 12 , a platform 13 , a driven wheel 14 , a driven wheel bogie 15 , and a platform support frame 16 . The chassis 11 is the support of each component of the robot, and carries each component of the system. The robot shell 12 is installed on the top of the chassis 11, fixed by a support frame, and the system hardware is sealed and protected (waterproof and dustproof). The gimbal 13 is a two-degree-of-freedom gimbal. The upper part is equipped with two housings that are respectively equipped with a high-definition visible light camera 22 and an optical gas infrared thermal imaging camera. Direction rotation range -90°~+90° pose adjustment to achieve real-time...

Embodiment 2

[0069] Embodiment 2: Embodiment 2 of the present invention provides a robot inspection method suitable for indoor semi-structured environments. This method can abandon manual intervention, realize automatic and autonomous patrol movement under a fixed trajectory, and can effectively avoid collisions with dynamic obstacles in the environment. This method has the advantages of simple control method, low calculation amount and low cost.

[0070] The inspection method adopted in the present invention takes into account the activity mode between human activities. In many cases, when we avoid behaviors during exercise, we often judge whether we should reduce our walking by judging the movement trend and speed of dynamic objects. speed, and we tend not to change the original walking path unless in a crisis state of collision. According to this general situation, the present invention plans a patrol route suitable for the current indoor environment in advance when considering the des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com