A kind of preparation method of 3D printing non-shaped self-deforming shape memory smart material

A 3D printing, smart material technology, applied in 3D object support structures, manufacturing tools, additive manufacturing, etc., to achieve the effect of simple process, saving production costs, and high forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method of a 3D printing non-shaped self-deforming shape memory smart material of the present invention, the method comprises:

[0039] Step 1: Design the structure of the material, and use Solidworks to model the material in 3D;

[0040] Step 2: Slice the model according to the design of step 1, and convert to generate STL format file;

[0041] Step 3: Input the STL format file into the 3D printing system, set the printing path and 3D printing parameters, and the cross angle between layers is 0°-180°;

[0042] Step 4: Using the fused deposition molding process, first restore the printing extrusion head and the bottom plate to the zero position, fine-tune the height of the extrusion head, and adjust the distance between the extrusion head and the bottom plate to be 0.2mm-0.6mm, so that the material can be printed in 3D. When pre-stretching the extruded filament, the limitation of the bottom plate or the adhesive layer allows the pre-stress to be preserved ...

Embodiment 1

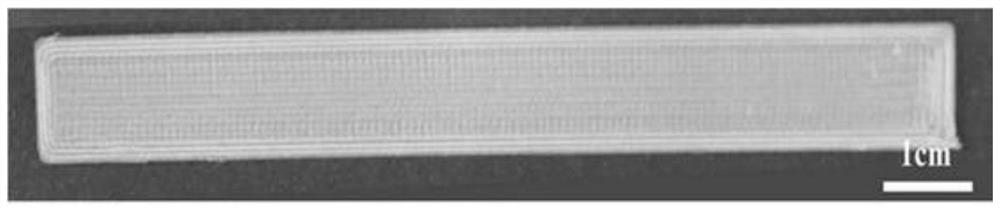

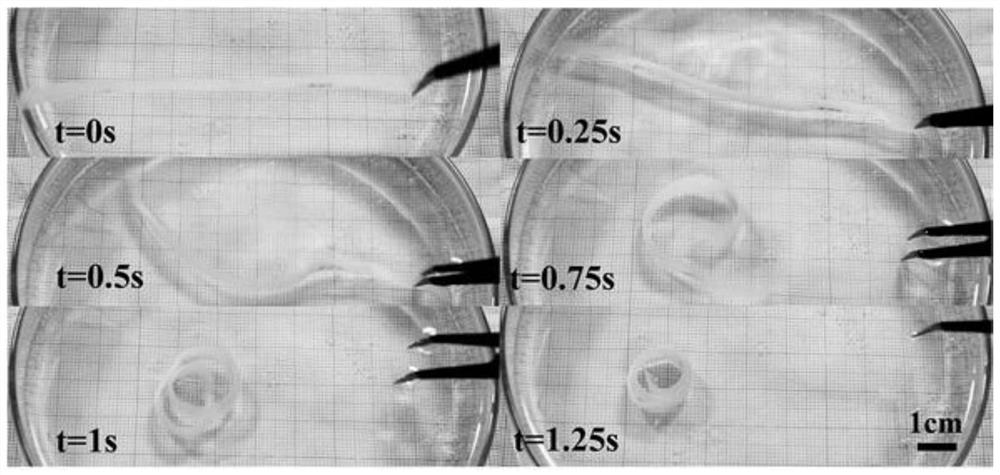

[0058] see figure 1 and image 3 shown;

[0059] Design size is 100ⅹ10ⅹ0.5mm 3 Use Solidworks to model the deformed material in 3D, then slice the model according to the design, convert it to generate an STL format file, and input the STL format file into the 3D printing system; then set the printing angle to 0°, the printer extrudes The head diameter is 0.4mm, the extrusion speed is 60mm / s, the extrusion head temperature is 195°C, the bottom plate temperature is 55°C, the filling rate is 100%, the printing layer thickness is 0.3mm, the interlayer crossing angle is 90°, and the maximum printing material per second is Volume 10mm 2 / s, the number of outer circles is 1, and the polylactic acid uses filament 3D printing consumables;

[0060] First, restore the printing extrusion head and the base plate to the zero position, fine-tune the height of the extrusion head, so that the distance between the extrusion head and the base plate is 0.4mm, and then print, and the finished ...

Embodiment 2

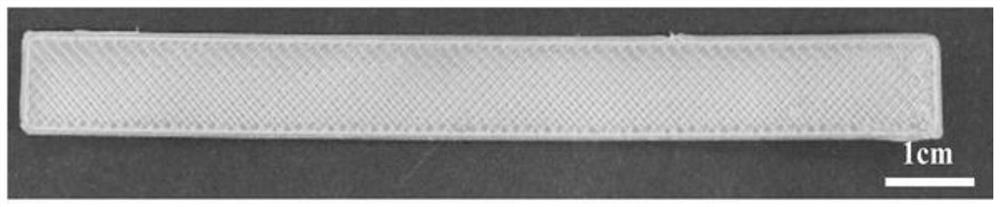

[0062] see figure 2 and Figure 4 shown;

[0063] Design size is 100ⅹ10ⅹ0.5mm 3 3D modeling of the deformed material with Solidworks, then slice the model according to the design, convert to generate STL format file, and input the STL format file into the 3D printing system; then set the printing angle to 45°, and the printer squeezes The diameter of the head is 0.4mm, the extrusion speed is 60mm / s, the temperature of the extrusion head is 195℃, the temperature of the bottom plate is 55℃, the filling rate is 100%, the printing layer thickness is 0.3mm, the cross angle between layers is 90°, and the maximum printing per second Material volume 10mm 2 / s, the number of outer circles is 1, and the polylactic acid uses filament 3D printing consumables;

[0064] First, restore the printing extrusion head and the base plate to the zero position, fine-tune the height of the extrusion head, so that the distance between the extrusion head and the base plate is 0.4mm, and then print...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com