Easy-to-atomize stone-like paint special for integrated plate and preparation method of easy-to-atomize stone-like paint

An integrated board, real stone paint technology, applied in the field of water-based building interior and exterior wall coatings, can solve the problems of low spraying efficiency, poor atomization effect, slow drying speed, etc., and achieve the effect of high spraying efficiency, fast drying speed, and improved drying speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing real stone paint special for easy-atomized integrated boards, the specific steps are as follows:

[0027] (1) Put a portion of water into the dispersion tank, adjust to 500-700 rpm, then add thixotropic lubricant and hydroxyethyl cellulose, and disperse for 3-5 minutes;

[0028] (2) Then adjust the rotation speed to 700-1000 rpm, add multifunctional additives, and disperse for 3-5 minutes;

[0029] (3) Then keep the rotation speed at 700-1000 rpm, then put in pure acrylate emulsion, disperse for 3-5 minutes, adjust the rotation speed to 500-700 rpm, then add bactericidal preservatives, freeze-thaw stabilizers, synthetic Membrane aid and alkali swelling thickener, continue to disperse for 3-5 minutes;

[0030] (4) Then keep the rotation speed at 500-700 rpm, then add natural colored quartz sand, stir evenly to get the real stone paint for easy atomization integrated board.

Embodiment 1

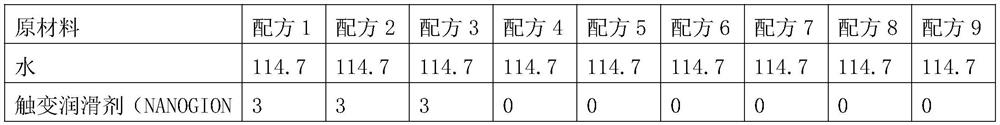

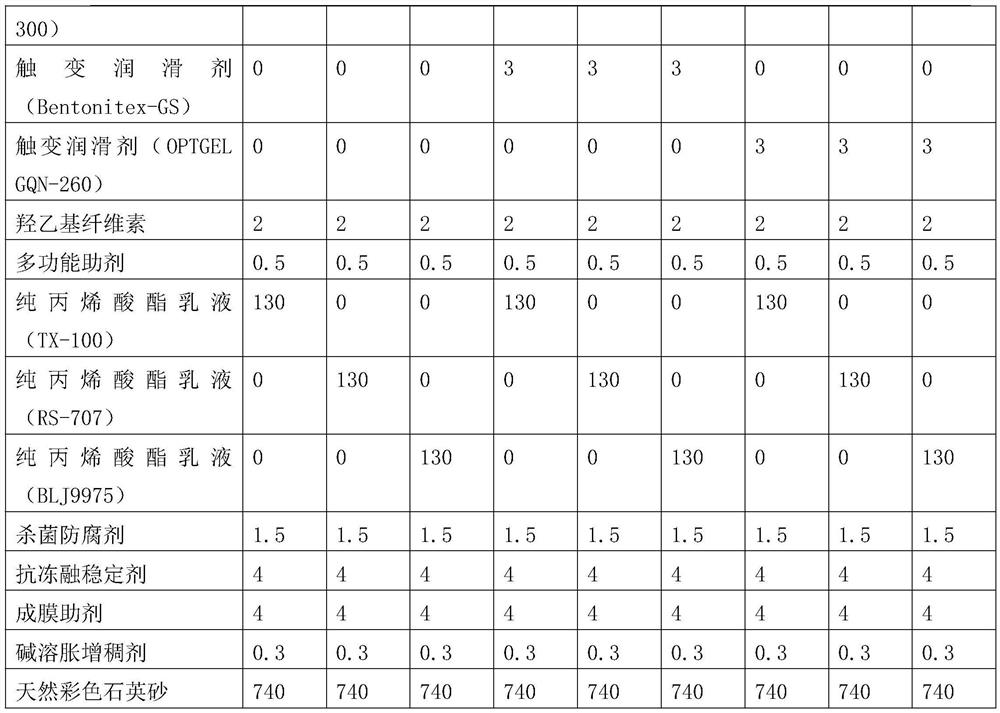

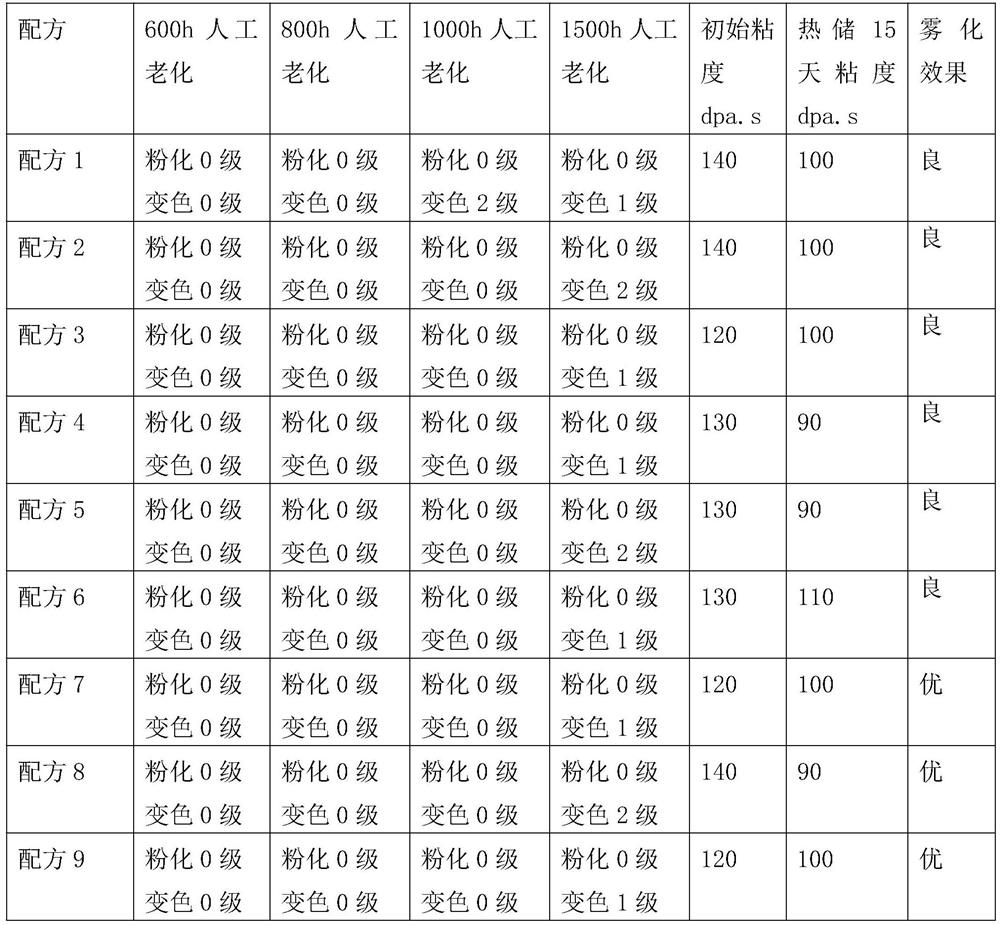

[0032] In order to achieve a good spray atomization effect, stable storage performance and excellent yellowing resistance, in this embodiment 1, a variety of thixotropic lubricants and a variety of pure acrylate emulsions in the special real stone paint formula for easy-atomization integrated boards were selected. The scheme of orthogonal collocation screening, respectively numbered "Formulation 1", "Formulation 2" ... "Formulation 9", is formulated according to the components and weight ratios shown in Table 1:

[0033] Table 1 Real stone paint formulations containing various thixotropic lubricants and various pure acrylate emulsions

[0034]

[0035]

[0036] The preparation method of the special real stone paint for the easy-atomized integrated board of this implementation is based on the following steps:

[0037] (1) Put water into the dispersion tank, adjust to 500 rpm, then add thixotropic lubricant and hydroxyethyl cellulose, and disperse for 5 minutes;

[0038] ...

Embodiment 2

[0047] In order to further optimize the storage performance of the formula, in Example 2, the cellulose in the real stone paint formula for the easy-to-atomize integrated board was selected, and a variety of cellulose comparative test schemes were used, respectively numbered "Formulation 10" ... "Formulation 13", Form by the composition shown in table 3 and the ratio of parts by weight:

[0048] Table 3 contains real stone paint formulations of different cellulose

[0049]

[0050] The preparation method of the special real stone paint for the easy-atomization integrated board of this embodiment is based on the following steps:

[0051] (1) Put water into the dispersion tank, adjust to 700 rpm, then add thixotropic lubricant and hydroxyethyl cellulose, and disperse for 3 minutes;

[0052] (2) Then adjust the rotation speed to 1000 rpm, add multifunctional additives, and disperse for 3 minutes;

[0053] (3) Then keep the rotation speed at 1000 rpm, then put in pure acrylate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com