Net-knot-free SE screen printing plate etching process

A knotless, screen technology, applied in the field of knotless SE screen etching process, can solve the problems of fine grid parallel direction steel wire and screen knot, unable to meet the strict control requirements of SE screen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

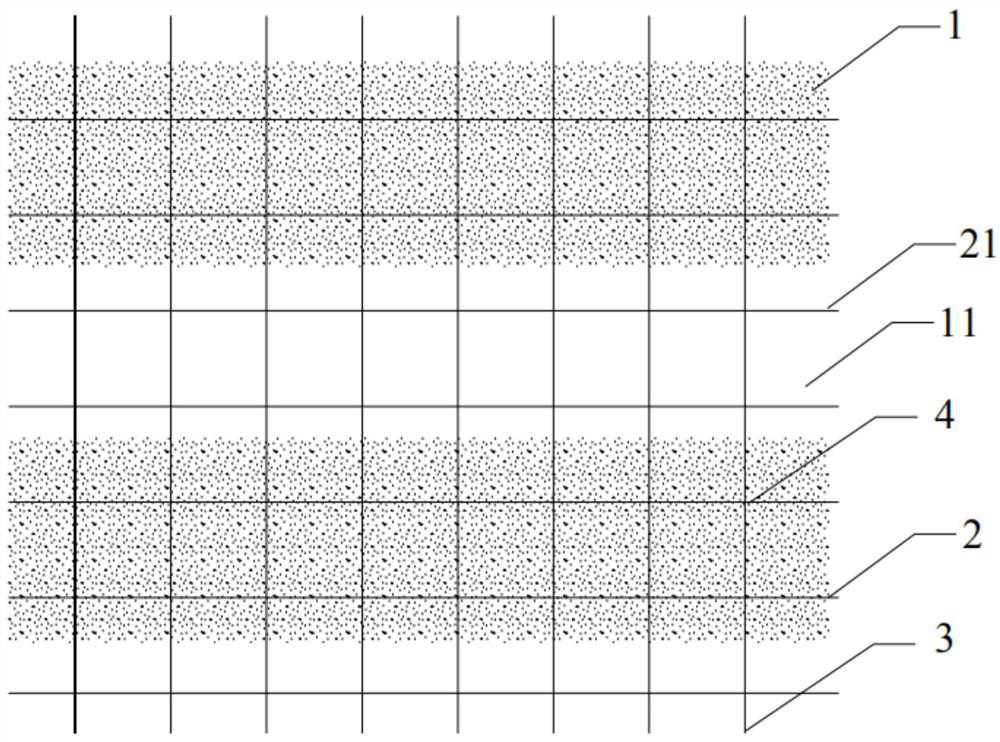

Image

Examples

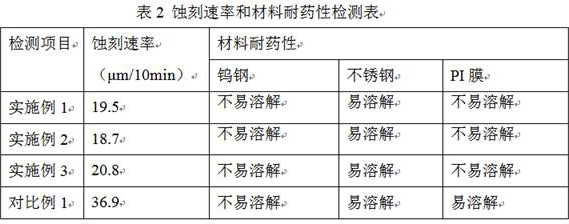

Embodiment 1

[0033] A kind of no mesh SE screen plate etching process, comprises the following steps:

[0034] S1 rinse

[0035] Clean the SE screen to be processed, and rinse the SE screen with deionized water for 60s;

[0036] S2 coating

[0037] Coating the photosensitive emulsion for the screen to form a protective film, the thickness of the protective film is 200 μm;

[0038] S3 pattern processing

[0039] Expose the screen according to the requirements, and then wash it. The obtained screen is as follows: the steel wire in a specific position is exposed, and the rest of the position is protected with a photosensitive emulsion.

[0040] S4 etching

[0041] Place the SE screen in the etching solution in the etching tank, and after the etching is completed, immerse it in the cleaning solution for cleaning.

[0042] Described etchant comprises the raw material of following percentage by weight:

[0043] HCl: 4%, FeCl 3 : 35%, H 3 PO 4 : 13%, NaCl: 1.5%, and the rest is water.

...

Embodiment 2

[0046] A kind of no mesh SE screen plate etching process, comprises the following steps:

[0047] S1 rinse

[0048] Clean the SE screen to be processed, and rinse the SE screen with deionized water for 20s;

[0049] S2 coating

[0050] Coating photosensitive emulsion for the screen to form a protective film, the thickness of the protective film is 100 μm;

[0051] S3 Exposure

[0052] Expose the screen according to the requirements, and then wash it. The obtained screen is as follows: the steel wire in a specific position is exposed, and the rest of the position is protected with a photosensitive emulsion.

[0053] S4 etching

[0054] Place the SE screen in the etching solution in the etching tank, and after the etching is completed, immerse it in the cleaning solution for cleaning.

[0055] Described etchant comprises the raw material of following percentage by weight:

[0056] HCl: 3%, FeCl 3 : 30%, H 3 PO 4 : 10%, NaCl: 1%, and the rest is water.

[0057] The cond...

Embodiment 3

[0059] A kind of no mesh SE screen plate etching process, comprises the following steps:

[0060] S1 rinse

[0061] Clean the SE screen to be processed, and rinse the SE screen with deionized water for 60s;

[0062] S2 coating

[0063] Coating the screen with polyimide to form a protective film, the thickness of the protective film is 12 μm;

[0064] S3 pattern processing

[0065] According to the requirements, laser is used to process the required pattern on the PI film, and the obtained screen is as follows: the steel wire in a specific position is exposed, and the remaining positions are protected by PI.

[0066] S4 etching

[0067] Place the SE screen in the etching solution in the etching tank, and after the etching is completed, immerse it in the cleaning solution for cleaning.

[0068] Described etchant comprises the raw material of following percentage by weight:

[0069] HCl: 5%, FeCl 3 : 40%, H 3 PO 4 : 15%, NaCl: 2%, and the rest is water.

[0070] The condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com