Three-dimensional anti-seismic steel structure factory building structure

A kind of building structure and anti-seismic technology, which is applied in the direction of building components, building structures, protective buildings/shelters, etc., can solve the problems of high price and achieve the effect of improving safety and reasonable overall structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

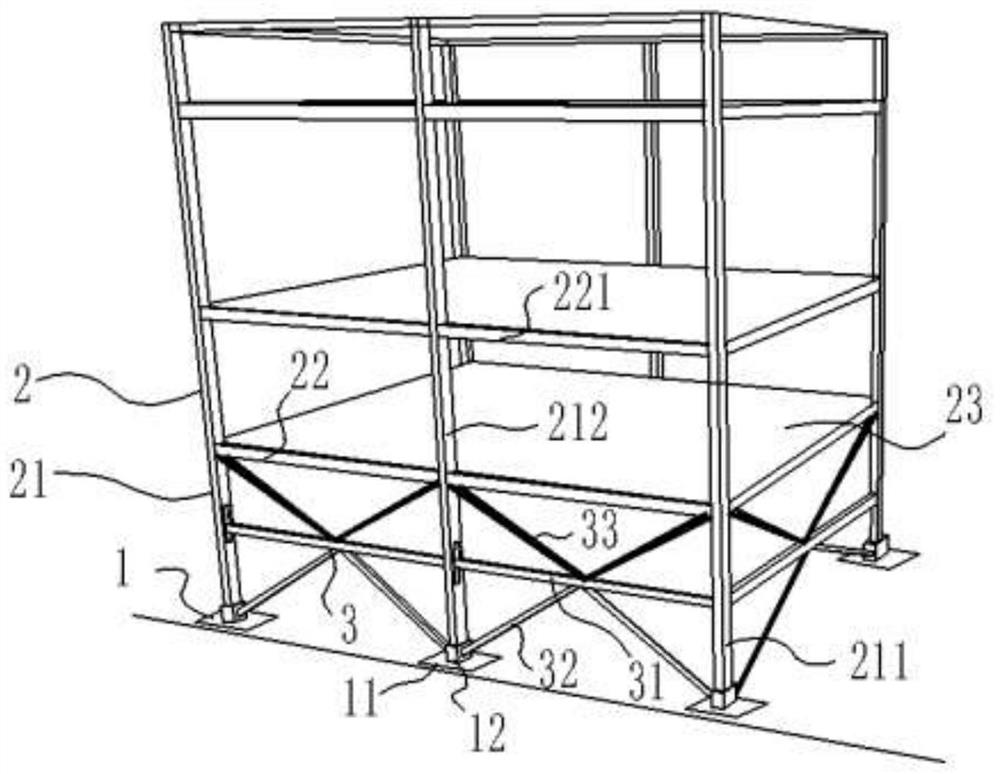

[0026] Embodiment 1: as figure 1 The three-dimensional anti-seismic steel structure factory building structure shown includes a pre-embedded structure 1 and a support structure 2 arranged on the pre-embedded structure 1; the support structure 2 includes a support column 21 installed on the upper end of the pre-embedded structure, installed on the support A beam structure 22 on the column 21, and a roof structure 23 installed on the beam structure 22;

[0027] Such as figure 1 As shown, the beam structure 22 includes an anti-seismic beam unit 3 arranged at the lower end of the support column 21, a support guide beam 221 evenly arranged on the support column 21, and a surface beam arranged between two parallel support guide beams 221 on the same horizontal plane;

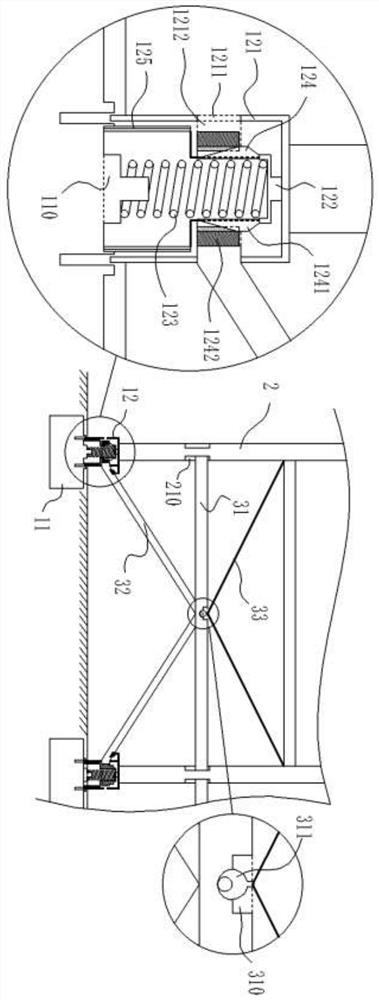

[0028] Such as figure 2 As shown, the anti-seismic beam unit 3 includes a shock-absorbing beam 31 installed between two adjacent supporting columns 21, two stilling ribs 32 with one end connected to the shock-absor...

Embodiment 2

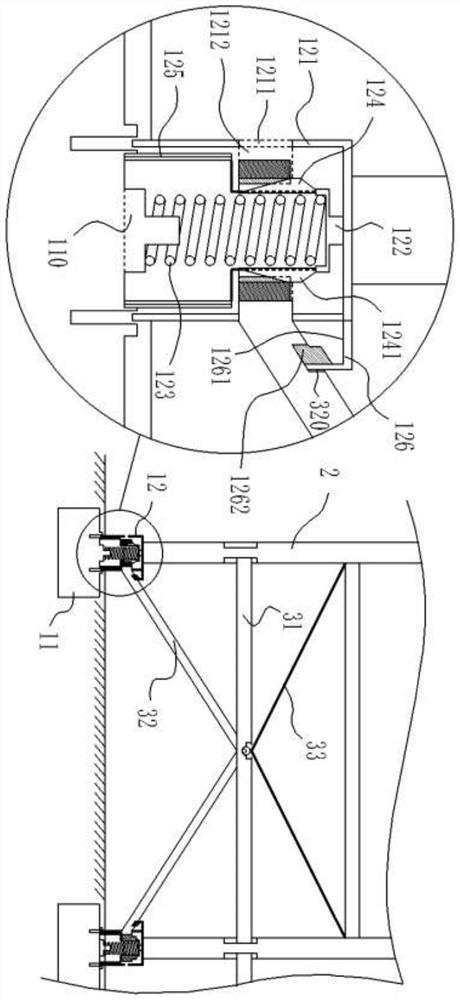

[0032] Embodiment 2: Different from Embodiment 1: as image 3As shown, the anti-seismic element 12 also includes a reset damping member 126; the stilling rib 32 is provided with a reset notch 320; The connecting rod 1261, and the second damping block 1262 installed on the reset connecting rod 1261 and located in the reset notch 320.

Embodiment 3

[0033] Embodiment 3: different from Embodiment 1: as Figure 4 As shown, the roof structure 23 includes a roof unit 231, and a stilling connector 232 for connecting the roof unit 231 to the supporting guide beam 221; The stilling net slats 2322 and the installation slots 2323 between the two fixing plates 2321;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com