Liquid copper alloy smelting device and implementation method thereof

A realization method and liquid copper technology, applied in the field of metal product processing, can solve problems such as difficulty in ensuring adequate mixing of materials, and achieve the effects of simple structure, high melting point and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

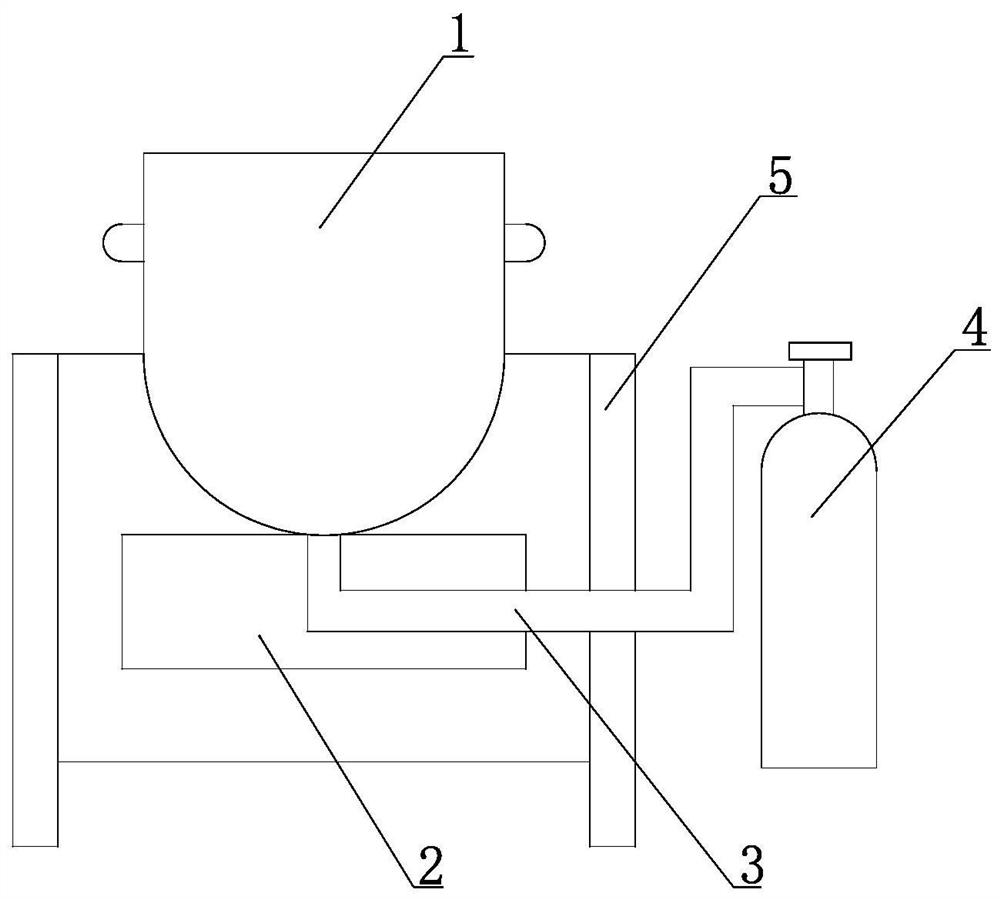

[0033] The present invention aims to provide a technical solution capable of fully melting the solid copper alloy so as to ensure subsequent die-casting effect and product quality. Structurally speaking, the device design for realizing the technical solution of the present invention is as follows: figure 1 As shown, it includes a melting pot 1 (preferably made of graphite) for placing a solid copper alloy, a heating device 2 for heating the melting pot so that the solid copper alloy in it is smelted into a liquid copper alloy, and a gas delivery device and hearth 5.

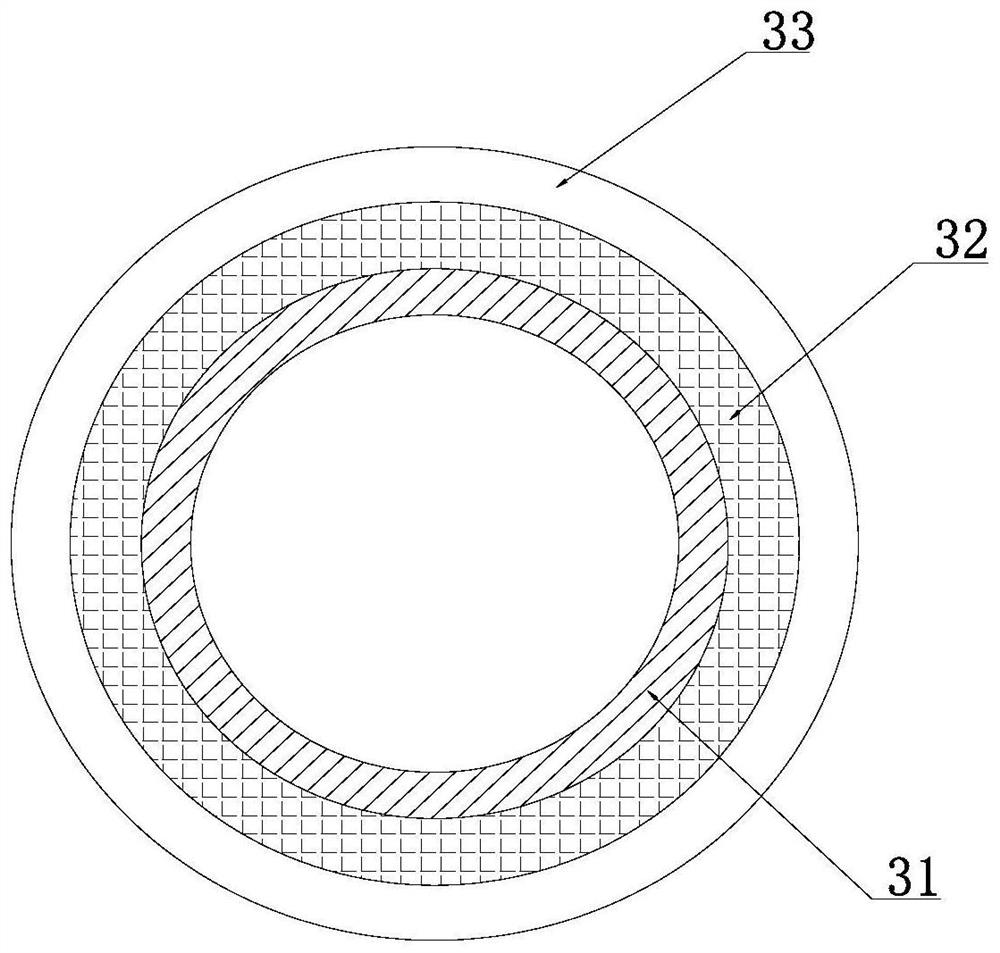

[0034] The gas delivery device is used to deliver gas to the melting pot during the process of heating the solid copper alloy, so that the copper alloy material that sinks at the bottom rolls upwards to achieve full mixing and heating of materials with different densities. Specifically, the The gas delivery device includes a gas delivery pipe 3 communicated with the melting pot 1 through a pipe body (the pipe bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com