Large amphibious aircraft hull watertight detection system and method

An amphibious aircraft and detection system technology, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement and measuring the acceleration and deceleration rate of fluid, etc., can solve the difficulty of leakage point detection, large volume, and the need for space for spray devices. and other problems, to achieve the effect of easy production and application, huge economic benefits, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

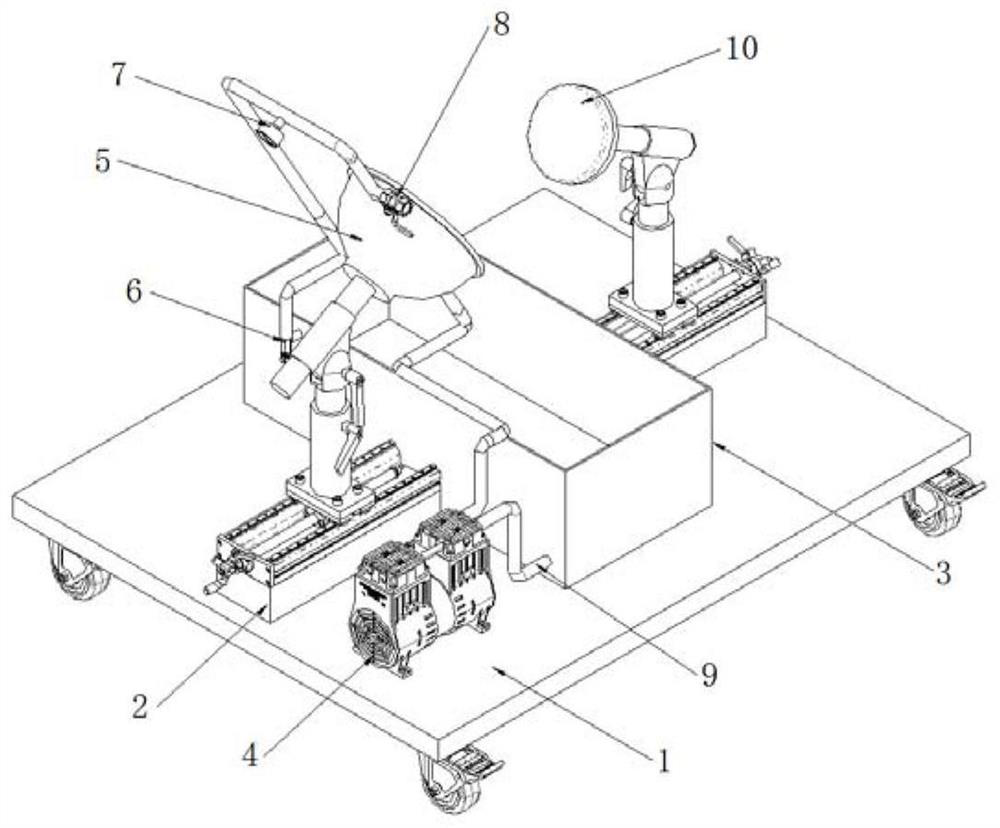

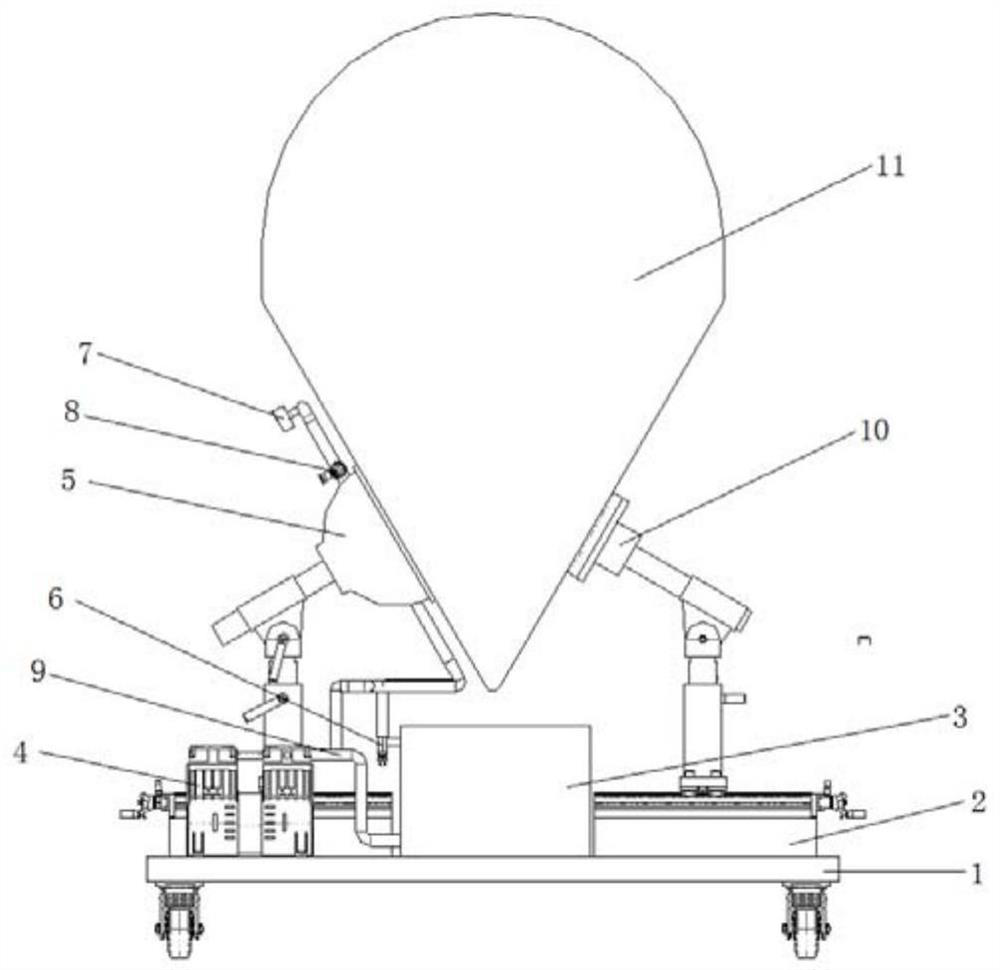

[0018] The purpose of the invention is to quickly, conveniently and accurately detect the leakage point of the hull in the outfield when the aircraft finds hull leakage during the water test flight in the outfield, so as to help eliminate hidden dangers of the aircraft and reduce the risk of subsequent flight tests. In order to achieve the above object, the present invention provides a large-scale amphibious aircraft hull watertight detection system and method, the following in conjunction with the attached Figure 1 to Figure 4 The present invention will be described in detail.

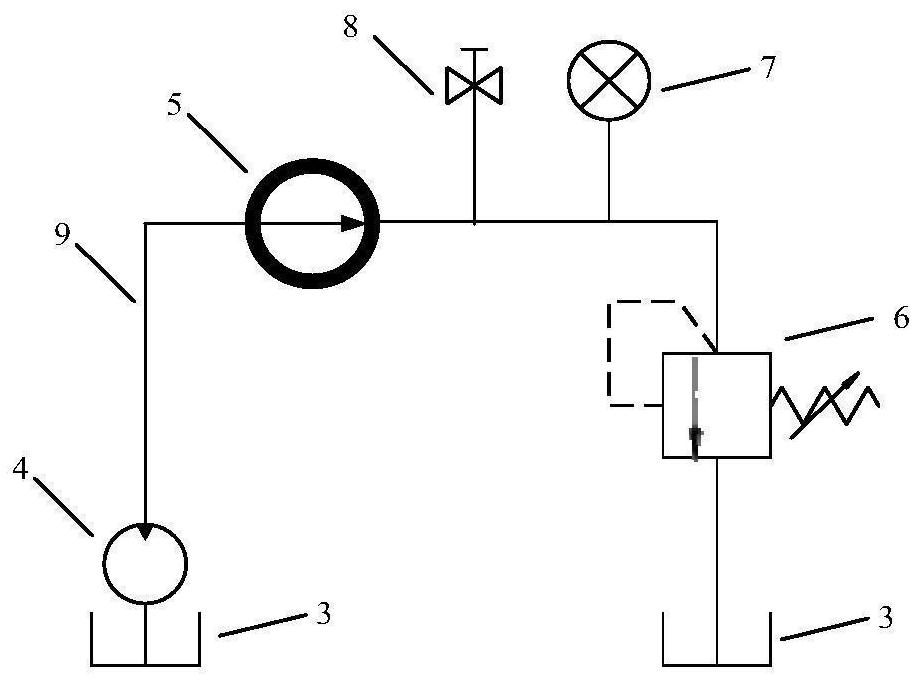

[0019] Such as figure 1 Shown:

[0020] The implementation of the present invention provides a large-scale amphibious aircraft hull watertight detection system, including a pool 3, a water pump 4, a leak detection plate 5, a vent valve 8, a pressure gauge 7, a manual overflow valve 6, and a water pipe 9; wherein the pool 3, The water pump 4, the manual overflow valve 6 and the water pipe 9 constitu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap