Measuring device for wet-end dragging force of dragging system

A measuring device and drag force technology, which is applied in the field of drag force measurement devices, can solve the problems of higher cost than a test on a lake, measurement of drag force at the wet end of a difficult tow system, and high related costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

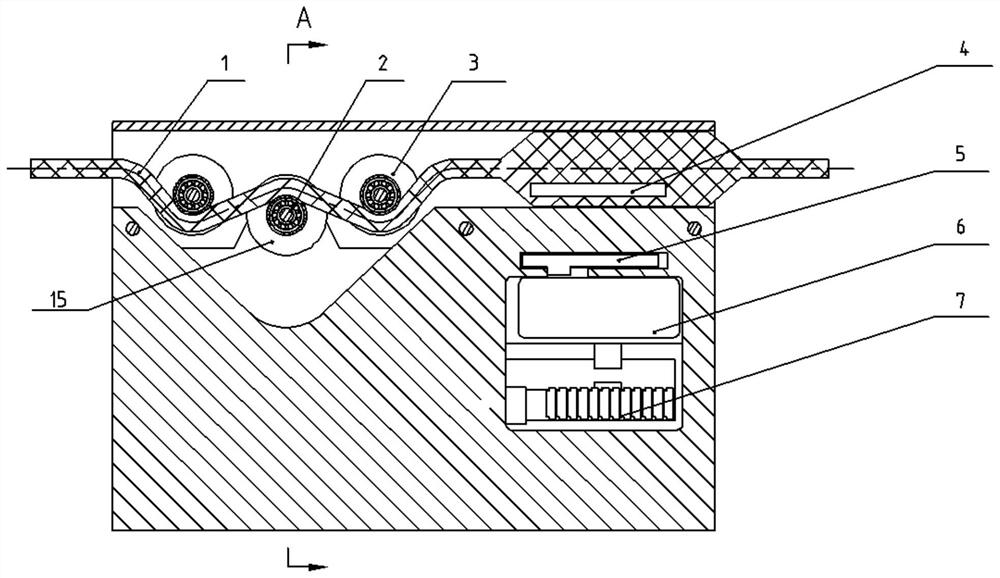

[0027] See attached figure 1 , 2 ,, a device for measuring drag force at the wet end of a towing system. The towing cable 1 in the towing system includes: a core wire for data transmission, a core wire for power supply, and a pair of twisted pairs. Twisted pair wires are used to communicate the measured wet end drag force data.

[0028] The first electromagnetic induction coil 4 is pre-embedded in the watertight layer at the wet end of the towing cable 1, and the first electromagnetic induction coil 4 and the towing cable 1 are vulcanized as one. After vulcanization, the diameter of this section of the towing cable 1 will become thicker. The electromagnetic induction coil 4 is connected in series with the twisted pair.

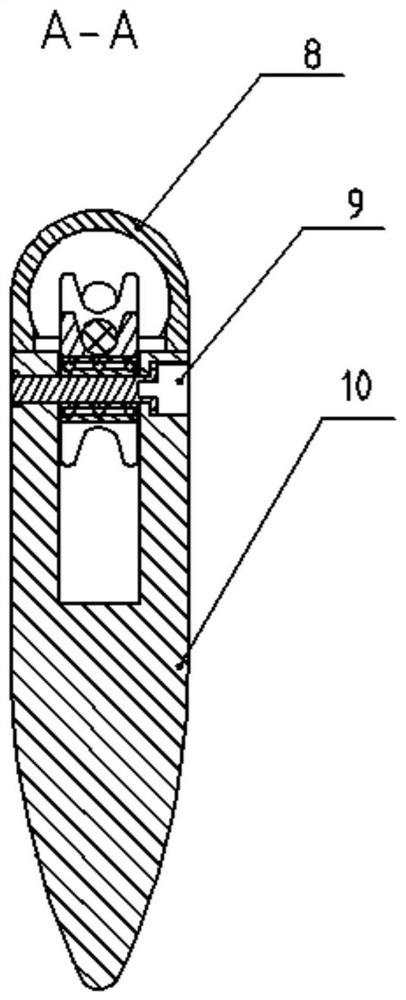

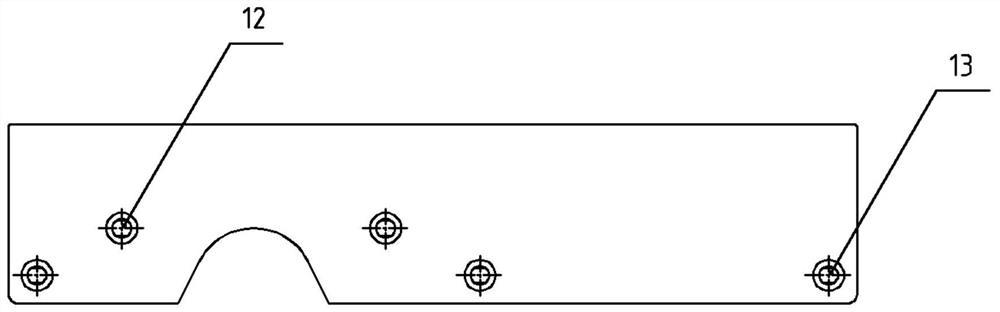

[0029] See attached Figure 3-8 , the tow cable 1 is arranged between the pad 8 and the guide vane 10; both the support pad 8 and the guide vane 10 have a guide shape to reduce the fluid force and the influence on the tension of the tow cable. The guide va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com