Molten slag surface tension prediction method based on melt structure analysis

A technology of surface tension and structure analysis, applied in surface tension analysis, surface/boundary effects, measurement devices, etc., can solve problems such as activity not being well treated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

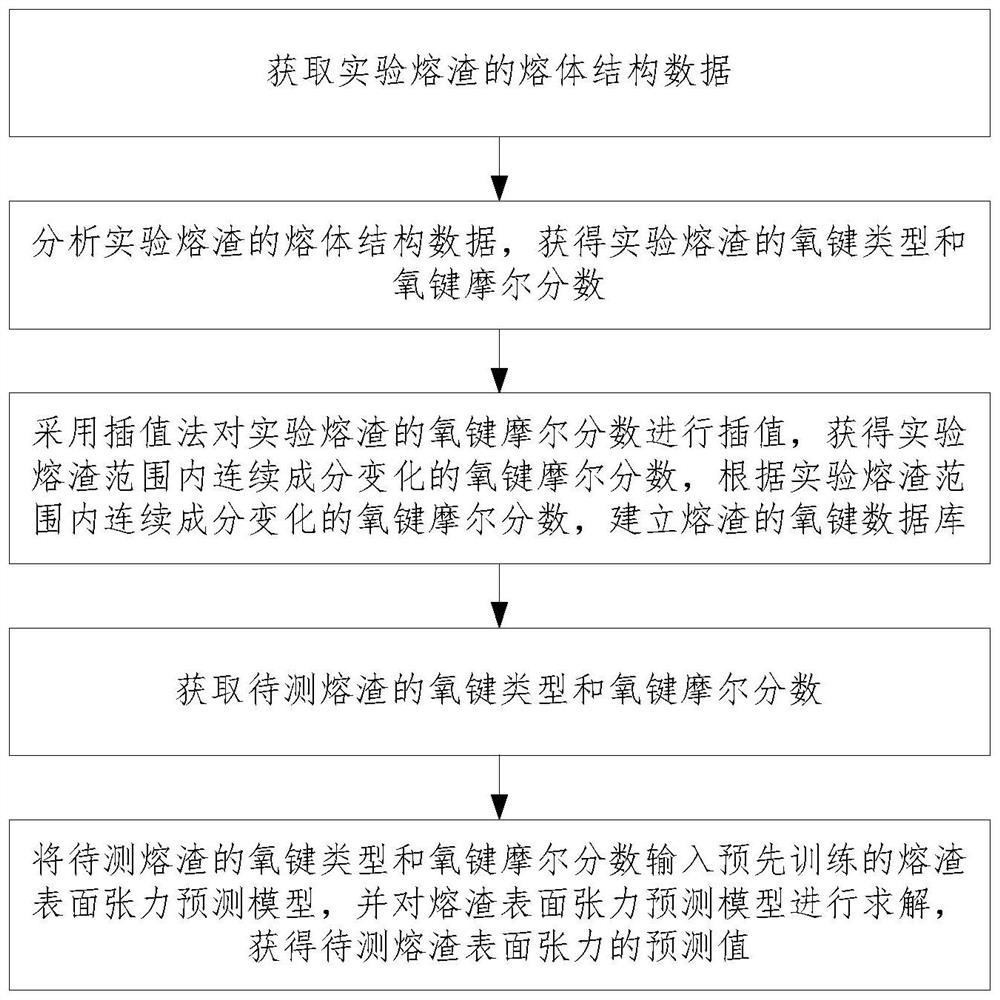

Method used

Image

Examples

Embodiment 1

[0081] Sample preparation: choose calcium oxide, magnesium oxide, silicon dioxide, ferrous oxalate dihydrate, and phosphorus pentoxide chemically pure reagents, and replace ferrous oxide with ferrous oxalate dihydrate. The experimental slags were prepared by changing the contents of calcium oxide, magnesium oxide, silicon dioxide, and phosphorus pentoxide, respectively, which were denoted as CMSFP1-CMSFP5. The specific components of the experimental slags were shown in Table 1, and the specific preparation methods were as follows:

[0082] Table 1 CaO-MgO-SiO 2 -Fe x O-P 2 o 5 Composition of experimental slag (mass fraction, %)

[0083]

[0084] 101. Put calcium oxide, magnesium oxide, and silicon dioxide pure reagents in Next calcined, spare.

[0085] 102. Weigh 3g of mixed chemical reagents as shown in Table 1, put them into a platinum crucible, and hang them in a high-temperature quenching furnace with a molybdenum wire, then feed 0.8L / min high-purity argon gas, an...

Embodiment 2

[0132] Sample preparation: choose calcium oxide, silicon dioxide, aluminum oxide, and ferrous oxalate dihydrate chemically pure reagents, in which ferrous oxide is replaced by ferrous oxalate dihydrate. The experimental slags were prepared by changing the contents of calcium oxide, silicon dioxide, aluminum oxide, and ferrous oxalate dihydrate, which were respectively recorded as CSAF1~CSAF10. The specific components of the experimental slags are shown in Table 2. The specific preparation methods are as follows:

[0133] Table 2 CaO-SiO 2 -Al 2 o 3 -Fe x The composition of O experimental slag (mass fraction, %)

[0134]

[0135] 101. Calcinate the pure reagents of calcium oxide, silicon dioxide and aluminum oxide at 600°C for later use.

[0136] 102. Weigh 3g of mixed chemical reagents as shown in Table 2, put them into a platinum crucible, and hang them in a high-temperature quenching furnace with a molybdenum wire, then feed 0.8L / min high-purity argon gas, and heat up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com