Method for quantifying coal lattice stripe length based on HRTEM

A fringe and lattice technology, which is applied in high-resolution transmission electron microscope testing and image processing in coal chemistry, can solve the problems of relying on manual extraction, heavy workload errors, etc., and achieve good matching degree of lattice fringe distribution, improve efficiency, and match good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

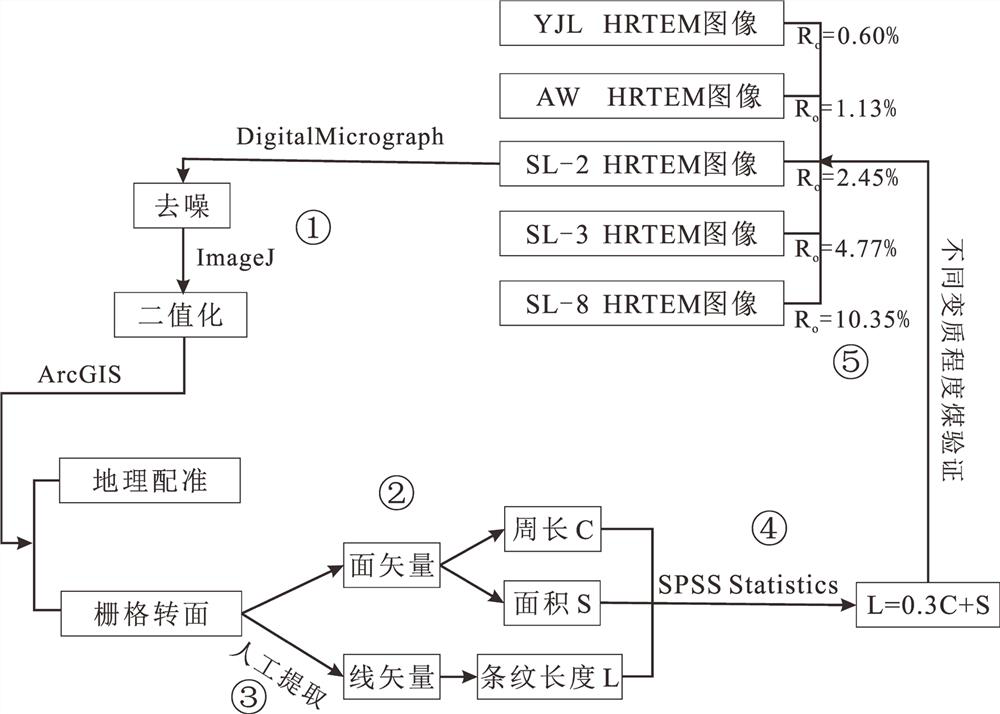

[0027] In this example, the high-resolution transmission electron microscope image processing process of Shuoli No. 2 coal (SL-2) is illustrated. The verified coal samples include Yujialiang coal (YJL), Aiweiergou coal (AW), and Shuoli No. 3 coal. Coal (SL-3), Shuoli No. 8 coal (SL-8). The degree of metamorphism of YJL, AW, SL-2, SL-3, and SL-8 increases in turn, and the reflectance of vitrinite is 0.60%, 1.13%, 2.45%, 4.77%, and 10.35%, respectively; to test the formula in turn for different coal For grade coal suitability, repeat steps 1,2,3,5.

[0028] Get 5g Shuoli No. 2 coal, and then carry out the following steps:

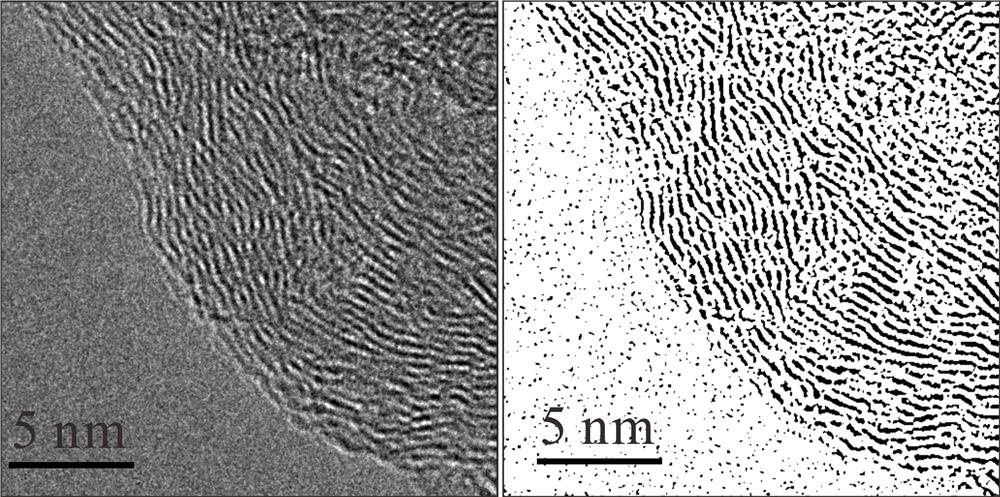

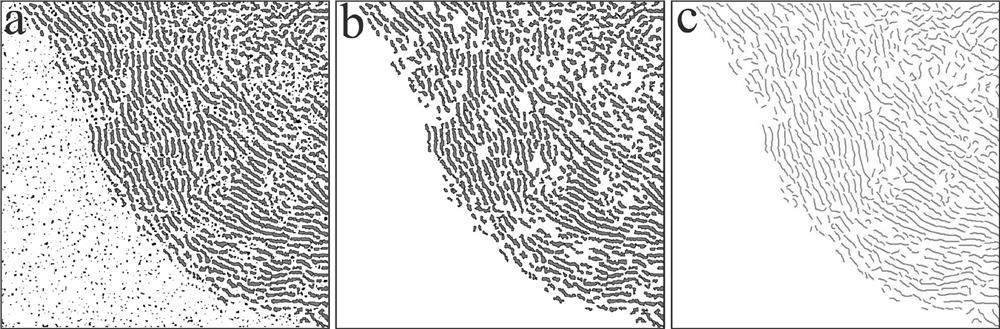

[0029] In step 1), the original coal sample was crushed and ground to below 200 mesh. After the sample was prepared, a high-resolution transmission electron microscope test was carried out, and the original electron microscope image obtained was subjected to preliminary processing: denoising based on DigitalMicrograph software, binarization by ImageJ softwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com