Outer ring grinding device for bearing production

A technology of bearing production and outer ring, which is applied in the field of bearing processing, can solve the problems of low grinding efficiency and only one grinding, and achieve the effect of improving grinding efficiency, improving work efficiency and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

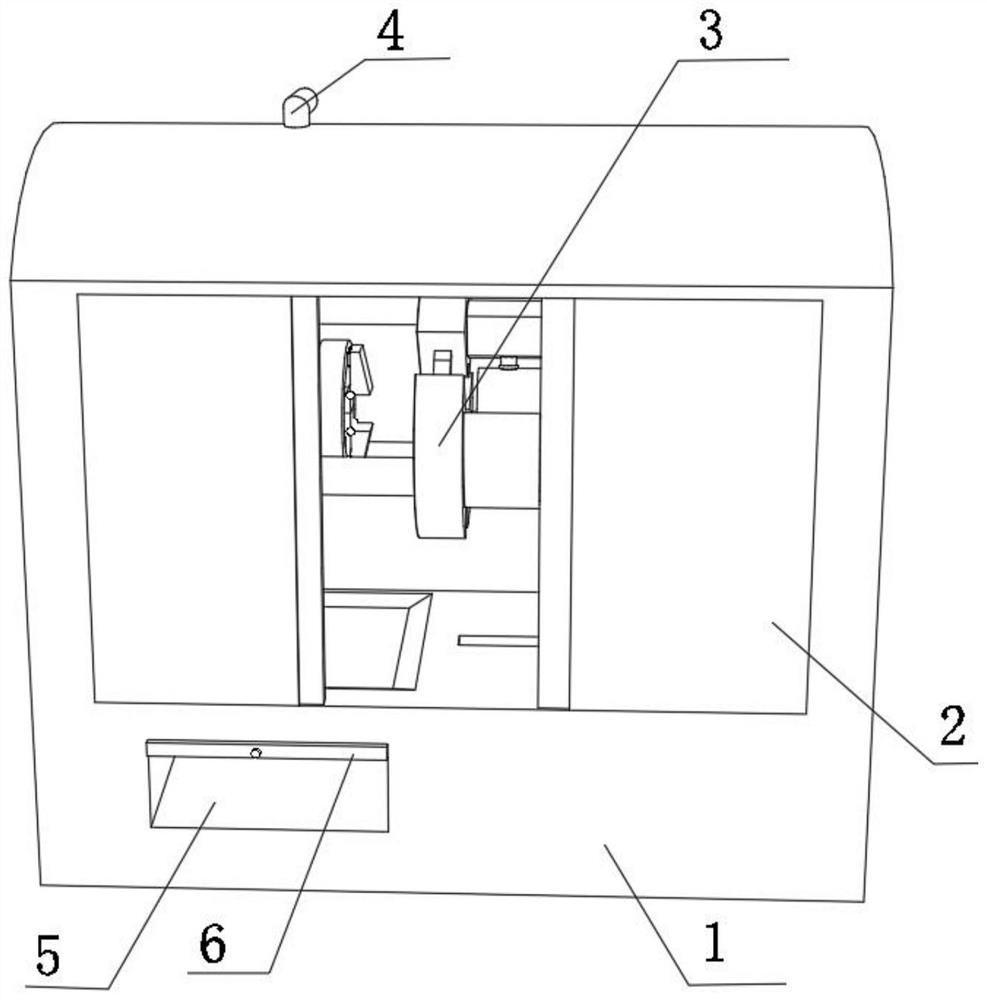

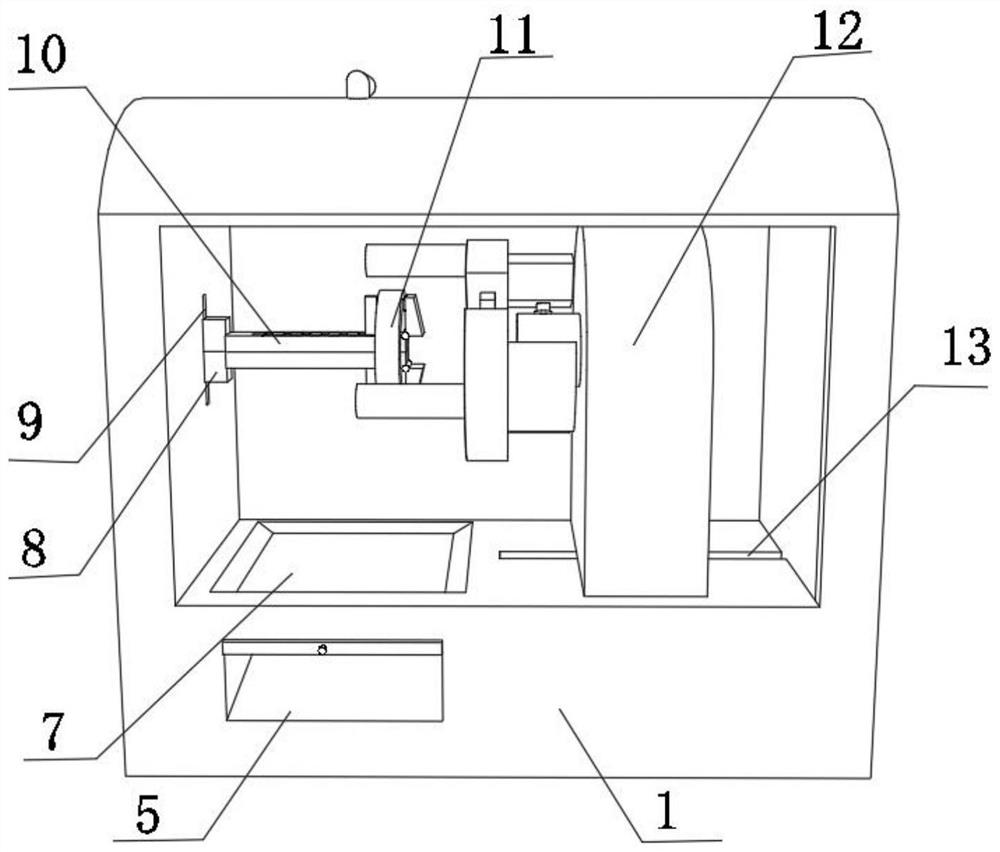

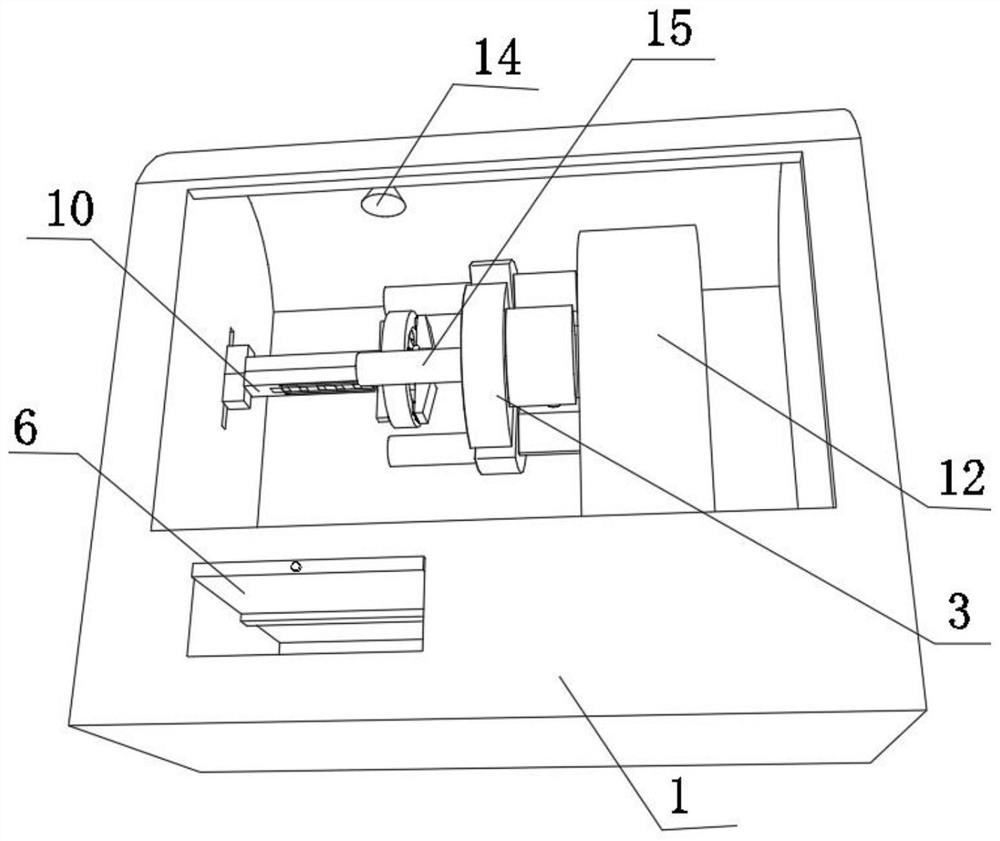

[0036] An outer ring grinding device for bearing production, such as Figure 1-5As shown, including the body 1, the inner wall of one side of the body 1 is provided with an adjustment groove 9, and the inner wall of the adjustment groove 9 is slidably connected with two connecting seats 8 through a slider, and the outer walls of one side of the two connecting seats 8 are all connected by bolts. The clamping seat 10 is fixed, and the top outer wall of one of the clamping seats 10 and the bottom outer wall of the other clamping seat 10 are provided with elongated grooves, and the inner walls of the two elongated grooves are slidably connected with the second clip through the slider. Holder plate, one side inner wall of two elongated slots are all welded with second spring 27, the other end of two second springs 27 is all welded on one side outer wall of two second clamping plates, two elongated slots are close to A side inner wall of the second spring 27 is fixed with a folded p...

Embodiment 2

[0043] An outer ring grinding device for bearing production, such as figure 1 and image 3 As shown, in order to facilitate the cleaning of waste; this embodiment makes the following improvements on the basis of embodiment 1: the inner wall of the discharge port 5 is inserted with a filter plate 6; the inner wall of the bottom of the body 1 is fixed with a nozzle by bolts 14. The input end of the nozzle 14 is welded with a water inlet 4. After grinding, waste debris needs to be cleaned or during grinding, in order to avoid sparks, an external water pipe is connected through the water inlet 4, and the nozzle 14 is opened for flushing. The waste debris after flushing is filtered to Staying on the filter plate 6 is convenient for unified treatment in the later stage, and the flushing water flows out through the bottom of the discharge port 5, which is convenient for collection and secondary use.

[0044] When this embodiment is in use, closing the retractable door 2 is convenien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com