Control method for backflow and dissolved oxygen of mixed liquid of MBR system

A technology of dissolved oxygen control and control method, which is applied in the field of mixed liquid reflux and dissolved oxygen control of MBR system, can solve the problems of consuming a large amount of sewage, affecting the denitrification effect of the system, and increasing the cost of sewage treatment, so as to reduce the energy consumption of the system and reduce Investment cost, effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] DETAILED DESCRIPTION OF THE INVENTION The technical solutions of the present invention will be further clarified and detailed in detail. This example is a preferred embodiment of the present invention, but the scope of the invention is not limited to the following examples.

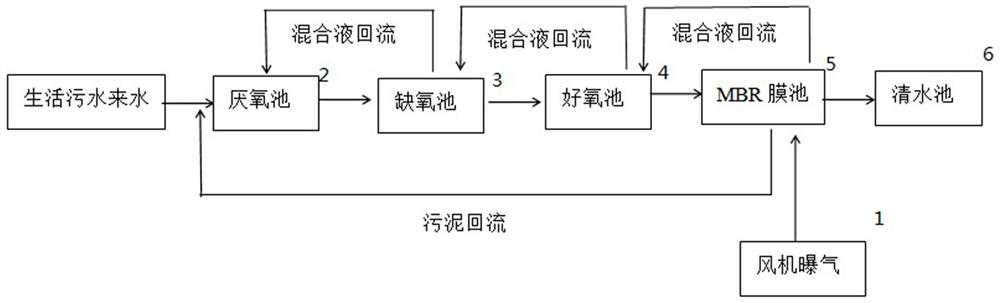

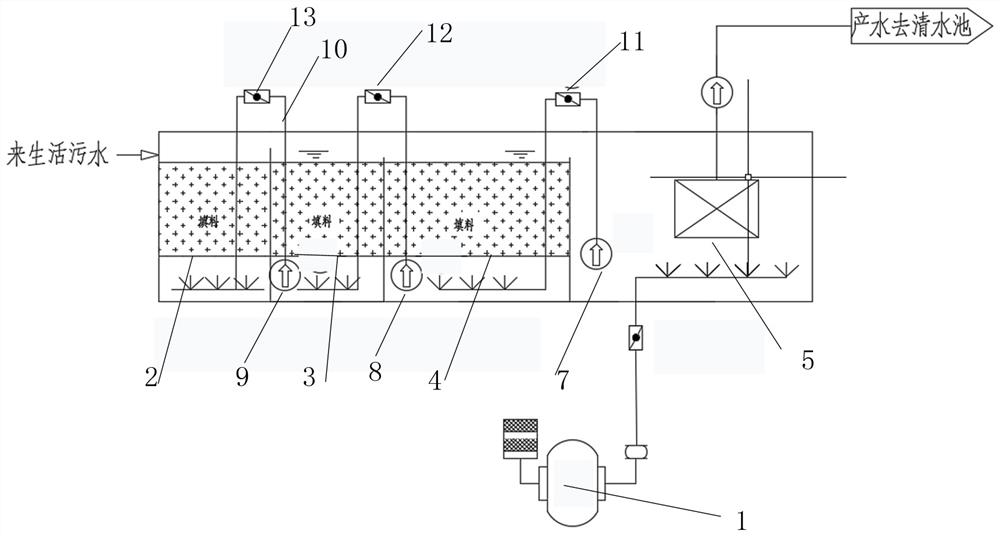

[0031] An MBR system mixture reflow and dissolved oxygen control method, the control method based on the control system includes: a fan 1, anaerobic pool 2, an oxygen pool 3, a good oxygen pool 4, an MBR film, a clear tank 6, and the first A refining pump 7, the second reflow pump 8, the third reflow pump 9, reflow pipe 10; the anaerobic pool 2, the oxygen pool 3, the aerobic pool 4, the MBR film pool 5, the water pool 6 in turn, The fan 1 is connected to the MBR film pond, and the MBR film pool 5 is provided with a first reflow pump 7, and a second reflow pump 8 is provided in the oxygen pool 4, and a third reflow pump 9 is provided in the hypoxic pool 3. The MBR film pool 5, the oxygen pool 4, the ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com