Storage device for preventing sludge from caking, and operation method

A material and sludge storage technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of low efficiency, poor working environment, time-consuming, etc., to prevent arching or hardening, prevent rewetting and fermentation, Effect of raising time to touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The following description is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

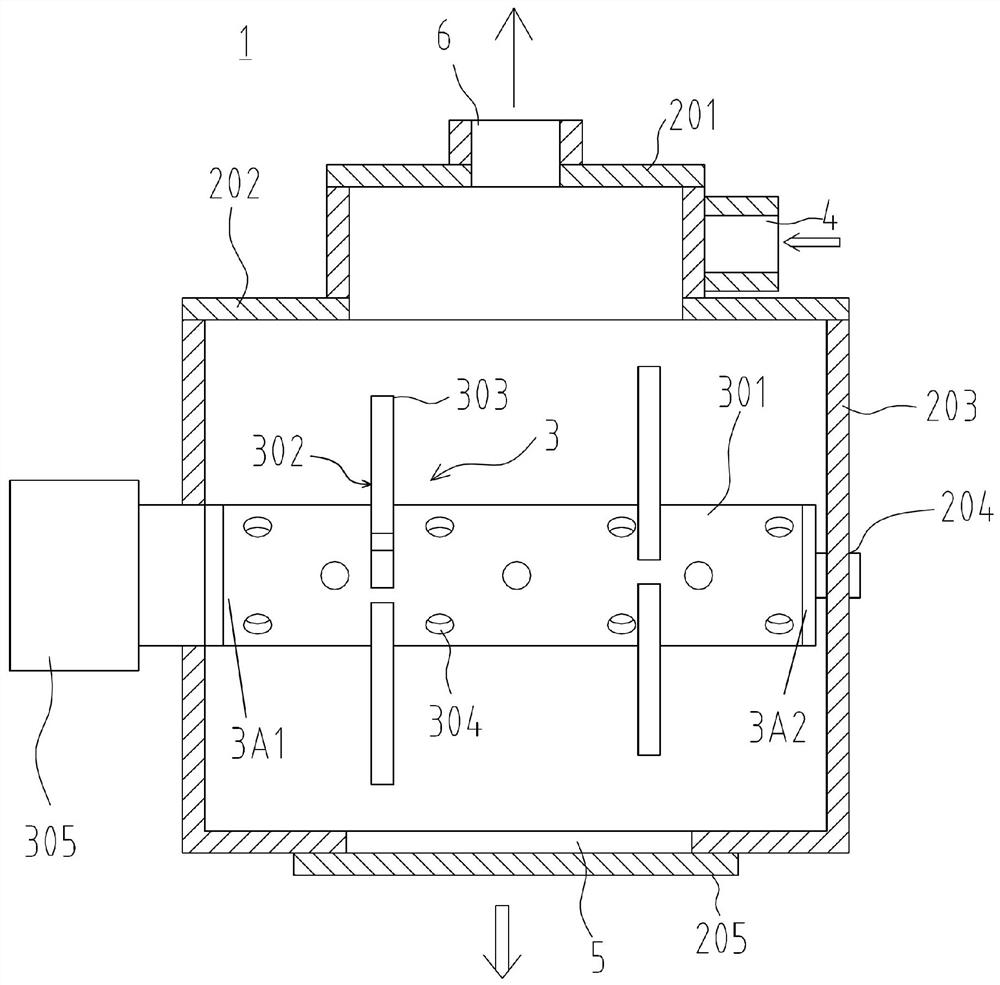

[0063] Such as figure 1 As shown, according to an example of the present invention, the storage device 1 has an inner space defined by a casing, and the casing includes an upper cover 202 and a main body 203 . The upper cover of the storage device is provided with at least one feed port 4 for transporting the dried sludge into the storage device, and at least one discharge port 5 is provided at the bottom of the housing for the The dried sludge is discharged from the storage device. exist figure 1 Only one feed opening 4 and one discharge opening 5 are shown in . It should be understood that the housing may comprise multiple feed ports 4 and / or multiple discharge ports 5 without going beyond the scope of the present invention. In another embodiment, the main body may further include a side wall and a bottom plate, and the feed inlet m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com