Production process of down-like non-glue cotton

A production process, non-adhesive cotton technology, applied in the directions of adhesives, fiber mixing, non-woven fabrics, etc., can solve the problem of not considering the mixing and adding method of ingredients, affecting the quality structure of down imitation non-adhesive cotton, and non-adhesive cotton laying and Baking effect and other problems, to achieve the effect of increasing the contact surface, ensuring comprehensiveness and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

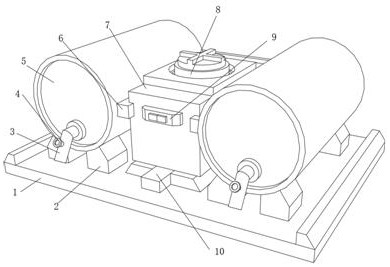

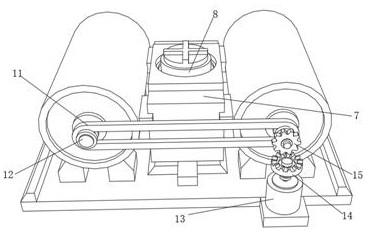

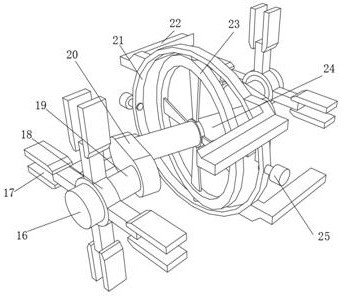

Image

Examples

Embodiment 1

[0034] A kind of production technology of down-like non-glued cotton, comprises the following steps:

[0035] S1: Prepare feather-like raw materials according to the mass ratio: 60% polyester fiber and 40% low-melting point fiber. At the same time, prepare non-glue cotton raw materials according to the mass ratio: 80% polymer fiber and 20% low-melting point fiber. The down-like raw material and the non-glued cotton raw material are mixed separately and divided into ingredient 1 and ingredient 2;

[0036] S2: Add the prepared ingredients 1 and 2 into the batching device at the same time at a ratio of 2:1 to configure the mixture, and add the finishing agent to the mixture;

[0037] S3: Put the prepared mixed material into the cotton production line equipment, and loosen and shape the cotton fabric through the cotton feeder, opener, cotton mixing box and carding machine in sequence, and loosen and shape the cotton fabric Put it into the net-laying machine to lay the net, and ge...

Embodiment 2

[0041] A kind of production technology of down-like non-glued cotton, comprises the following steps:

[0042] S1: Prepare feather-like raw materials according to the mass ratio: 60% polyester fiber and 40% low-melting point fiber. At the same time, prepare non-glue cotton raw materials according to the mass ratio: 80% polymer fiber and 20% low-melting point fiber. The down-like raw material and the non-glued cotton raw material are mixed separately and divided into ingredient 1 and ingredient 2;

[0043] S2: Add the prepared ingredient 1 and ingredient 2 intermittently into the batching device at the same time at a ratio of 2:1 to configure the mixture, and add a finishing agent to the mixture;

[0044] S3: Put the prepared mixed material into the cotton production line equipment, and loosen and shape the cotton fabric through the cotton feeder, opener, cotton mixing box and carding machine in sequence, and loosen and shape the cotton fabric Put it into the net-laying machine...

Embodiment 3

[0048] A kind of production technology of down-like non-glued cotton, comprises the following steps:

[0049] S1: Prepare feather-like raw materials according to the mass ratio: 60% polyester fiber and 40% low-melting point fiber. At the same time, prepare non-glue cotton raw materials according to the mass ratio: 80% polymer fiber and 20% low-melting point fiber. The down-like raw material and the non-glued cotton raw material are mixed separately and divided into ingredient 1 and ingredient 2;

[0050] S2: Add the prepared ingredient 1 and ingredient 2 into the batching device at the same time and continuously in the ratio of 2:1 to configure the mixture, and add the finishing agent to the mixture;

[0051] S3: Put the prepared mixed material into the cotton production line equipment, and loosen and shape the cotton fabric through the cotton feeder, opener, cotton mixing box and carding machine in sequence, and loosen and shape the cotton fabric Put it into the net-laying m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com