Sensing control method of wide-range pressure wave sensor

A control method and pressure wave technology, applied in the field of sensors, can solve the problems of pressure wave sensors that are prone to zero point drift, the distance between capacitors should not be too large, and the zero point deviation is large, so as to achieve low sound pressure measurement with high sensitivity, expand the measurement range, The effect of wide frequency response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

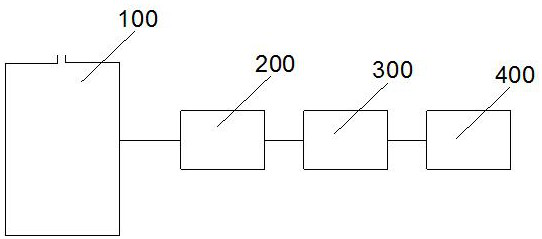

[0029] see figure 1 , a sensing control method for a wide-range pressure wave sensor, comprising a wide-range pressure wave sensor 100 , a signal converter 200 , a data processor 300 and a display 400 . The wide-range pressure wave sensor 100 has a power input end and a signal output end, and the power input end is used for connecting with a signal source. The input end of the signal converter 200 is connected to the output end of the wide-range pressure wave sensor 100 for obtaining the detection signal of the wide-range pressure wave sensor 100 and converting the detection signal. The input terminal of the data processor 300 is connected with the output terminal of the signal converter 200 for obtaining the converted detection signal. The output terminal of the data processor 300 is electrically connected with the display 400 . The obtained converted detection signal is processed by the data processor 300 and displayed by the display 400 .

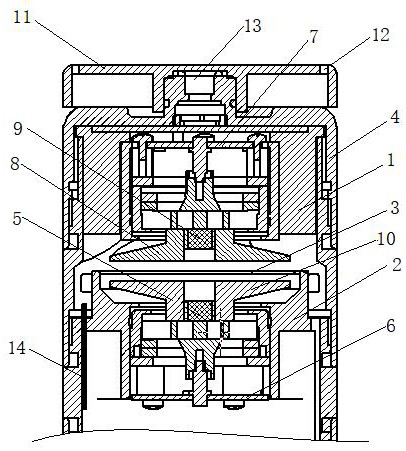

[0030] see figure 2, the wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com