Underground diaphragm wall reinforcement cage manufacturing and hoisting construction method

An underground diaphragm wall and steel cage hoisting technology, which is applied in excavation, sheet pile walls, and foundation structure engineering, can solve problems such as difficulty in finding space conflicts in drawings, lack of guidance for workers to explain, and difficulty in ensuring the accuracy of steel cages, etc., to achieve Clear and intuitive inspection and prediction, easy inspection and prediction, and the effect of improving construction accuracy and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the techniques, innovative features of the present invention, the purpose and efficacy are readily understood, and the present invention is further illustrated below.

[0053] The embodiments described herein are intended embodiments of the invention, and are intended to illustrate the embodiments of the present invention, and should not be construed as limiting the embodiments of the invention and the scope of the invention. In addition, according to the implementation exceptions described herein, those skilled in the < Replacement and modification of technical solutions.

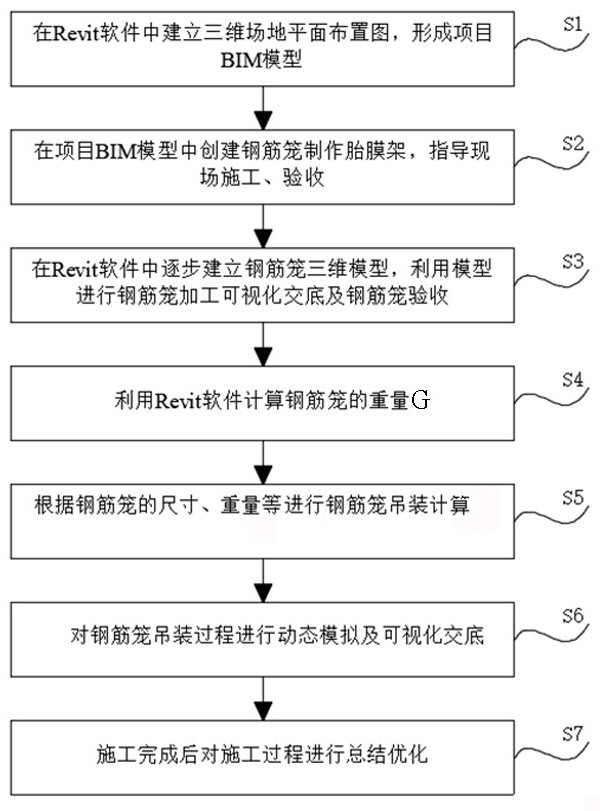

[0054] figure 1 A flow chart of a preference for the production and lifting construction method of the underground continuous wall steel cage of the present invention.

[0055] In this preferred example, a sub-continuous wall steel cage is made and lifting construction method, including the following steps:

[0056] S1, establish a three-dimensional field plane arrangement in the Revi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap