Flow heat transfer and automatic control research platform and method

A platform and temperature sensor technology, applied in the testing of machine/structural components, instruments, electrical digital data processing, etc., can solve the problems of non-repeatability, difficult to accurately control the cooling process, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

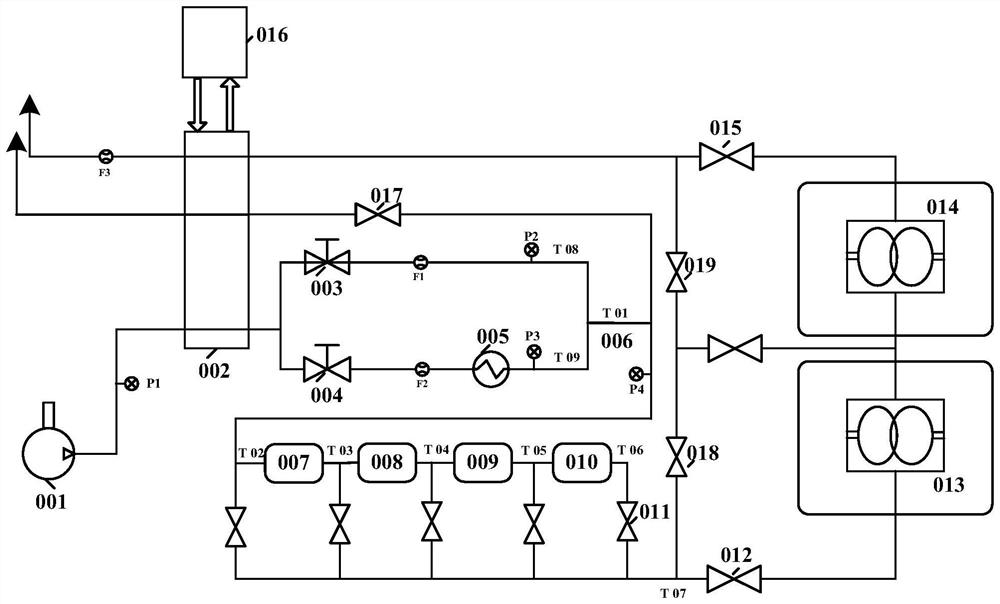

[0035] The schematic flow chart of the flow heat transfer and automatic control research platform of the present invention is as follows figure 1 shown in figure 1 Medium, mainstream working medium: air; pressure source: mobile screw air compressor (1.3MPa); heating method: electric heater; cooling method: water chiller + water / air shell-and-tube heat exchanger (cooling water tower); heat insulation Method: aluminum silicate cotton; pipe: DN25 304 stainless steel electropolished tube, which is a long spiral type, wrapped with heat insulating material; pipe connection method: welding and flange, temperature measurement method: PT100 thermal resistance; pressure measurement method: pressure sensor and differential pressure sensor; flow measurement method: vortex flowmeter*2+mass flowmeter*1; measurement and control method: PC upper computer+PLC to control the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com