Industrial solid waste whole-process real-time monitoring system and method

A solid waste, real-time monitoring technology, applied in closed-circuit television systems, logistics, time registers, etc., can solve the problems of incomplete information acquisition, low level of information processing, and difficulty in illegal evidence collection, so as to improve work efficiency and management level. , the effect of reducing legal risks and labor costs, and preventing integrity risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

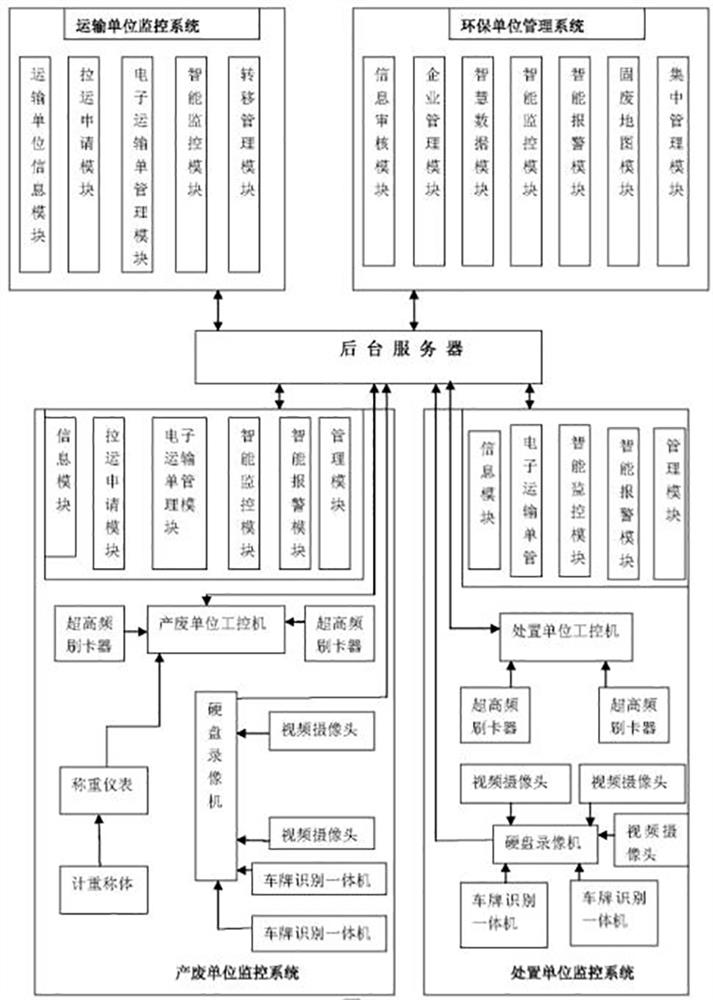

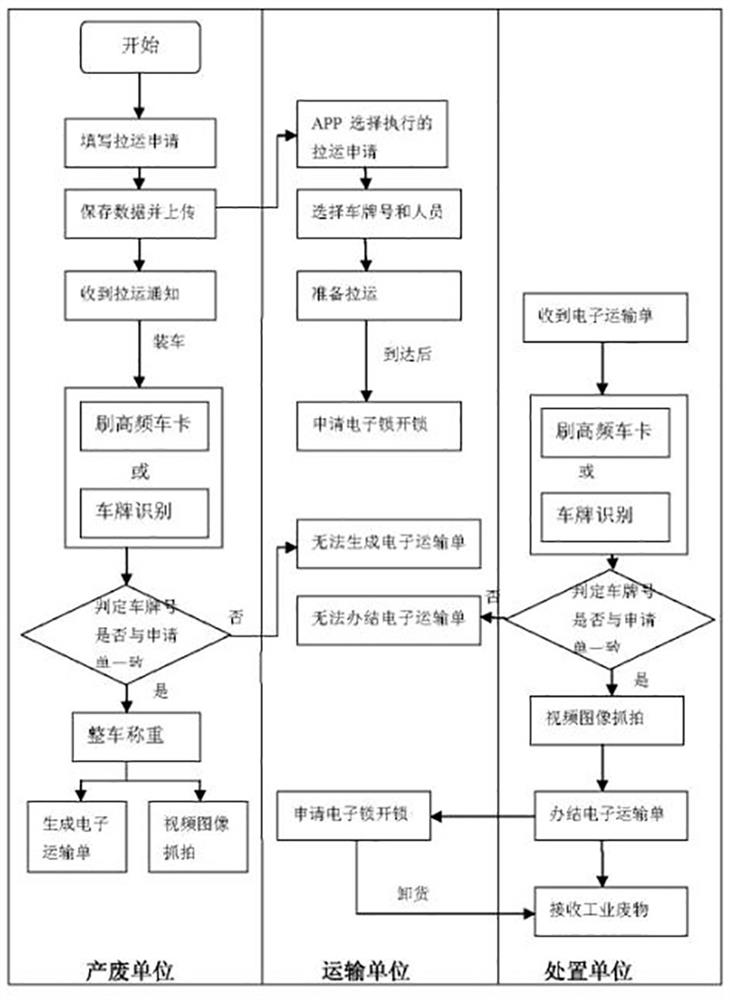

[0034] The invention provides a real-time monitoring system for the whole process of industrial solid waste, such as figure 1As shown, it includes the background server and the monitoring system of the waste production unit, the monitoring system of the transportation unit, the monitoring system of the disposal unit, and the management system of the environmental protection unit.

[0035] Among them, the waste production unit monitoring system includes a waste production unit information module, a delivery application module, an electronic transport order management module, an intelligent monitoring module, an intelligent alarm module and a generation source management module. These modules are the webpage management terminals of the waste production unit monitoring system . The intelligent monitoring module of the waste production unit also includes a video camera installed in the storage area and loading area of the waste production unit, and the signal output end of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com