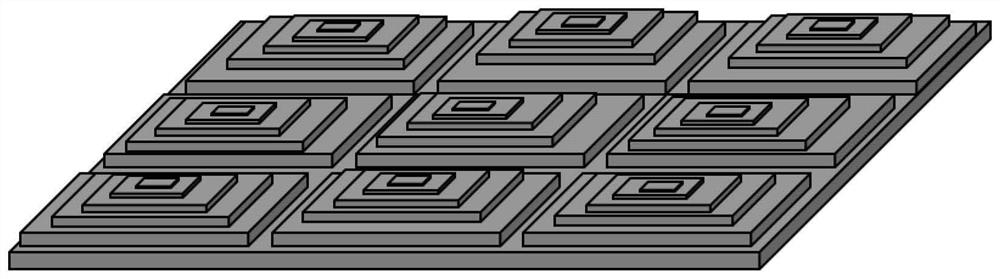

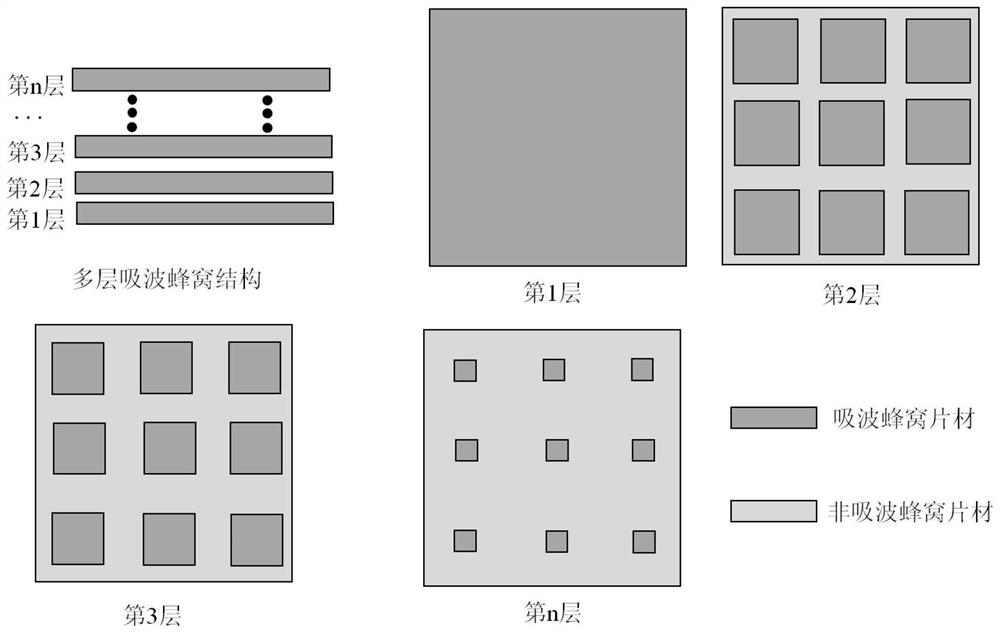

Wave-absorbing honeycomb with pyramid-like structures and preparation method of wave-absorbing honeycomb

A pyramid and honeycomb technology, which is applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problem that the wave absorbing honeycomb pyramid cannot be used as a structural load-bearing member, etc., and achieves easy process control and stable performance. , the effect of high absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

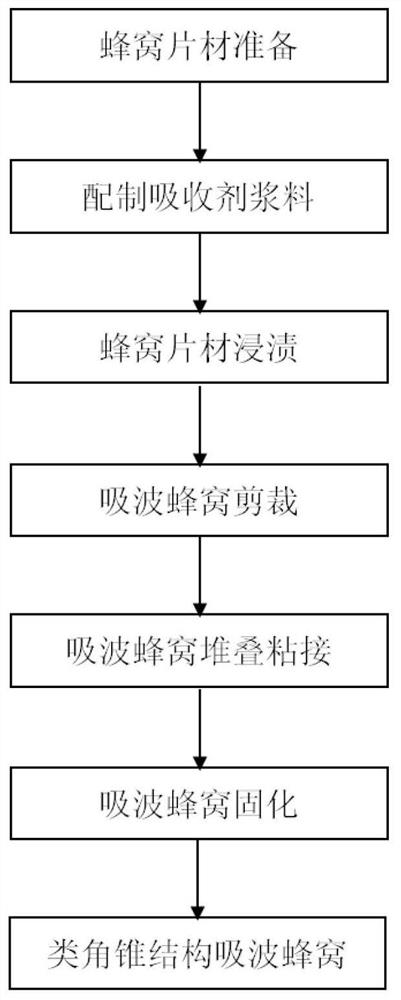

[0057] Step 1: Select a density of 48kg / m 3 , a honeycomb block with a cell size of 3.2mm, which is sliced into a honeycomb sheet of 300mm×300mm×5mm by a cutting machine.

[0058] Step 2: Take a certain quality of conductive carbon black, water-soluble honeycomb modified epoxy resin, curing agent and deionized water, wherein the total mass of conductive carbon black and resin (containing curing agent) is 500g, and conductive carbon black and resin The weight ratio (including curing agent) is 1:1, and the plasma water is 5000g. Put the conductive carbon black, resin, curing agent and a small amount of plasma water into the container for high-speed mechanical stirring for 10 minutes, then gradually add the remaining plasma water into the container, and get the absorbent slurry after stirring evenly. After the foam on the surface of the slurry is eliminated, use the Tu-4 cup to monitor the viscosity of the absorbent slurry, and the viscosity value is 12-13s. Pour the configur...

Embodiment 2

[0065] Choose a density of 48kg / m 3 A honeycomb block with a cell size of 4.8 mm is used as the base material. A total of 8 honeycomb pyramids were impregnated and dried, and the rest were the same as in Example 1 to obtain a microwave-absorbing honeycomb with a pyramid-like wave-absorbing structure. The reflectivity test curve of the absorbing honeycomb is as follows Figure 5 shown.

Embodiment 3

[0067] Step 1: Select a density of 80kg / m 3 , a honeycomb block with a cell size of 3.2mm, which is sliced into a honeycomb sheet of 500mm×500mm×10mm by a cutting machine.

[0068] Step 2: Take a certain quality of conductive carbon black, water-soluble honeycomb modified epoxy resin, curing agent and deionized water, wherein the total mass of conductive carbon black and resin (containing curing agent) is 1200g, and conductive carbon black and resin The weight ratio (including curing agent) is 1:3, and the plasma water is 6000g. Put the conductive carbon black, resin, curing agent and a small amount of plasma water into the container for high-speed mechanical stirring for 10 minutes, then gradually add the remaining plasma water into the container, and get the absorbent slurry after stirring evenly. After the foam on the surface of the slurry is eliminated, use the Tu-4 cup to monitor the viscosity of the absorbent slurry, and the viscosity value is 10-11s. Pour the config...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com