Organic amine phosgenation reactor and process

A technology for reactors and organic amines, applied in the field of organic amine phosgenation reactors and processes, to achieve the effects of solving solid problems, significant economic benefits, and easy regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

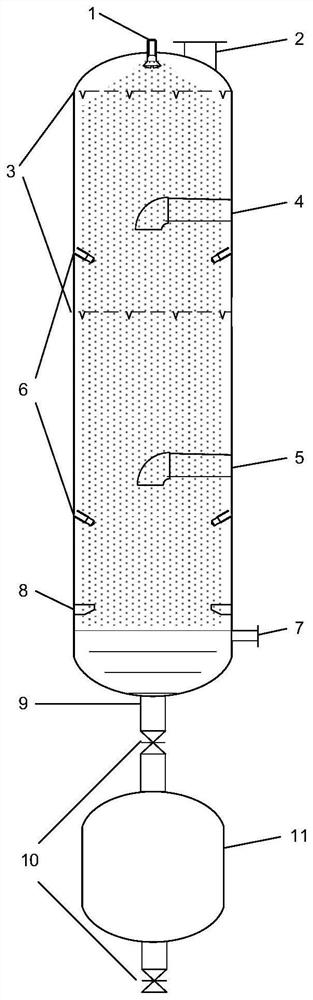

[0082] Refer below figure 1 Specific description according to the specific mode of operation of the preparation process of the present disclosure:

[0083] 1) The prepared organic amine solution has a mass concentration of 10-70%, preferably 20-50%, and after heat exchange, the feed temperature is 0-65°C, and is sprayed downwards into the reactor from the feed atomizing nozzle 1, The spraying angle is 20-160°, preferably 40-120°, more preferably 60-100°. The sprayed liquid mist is in the shape of a solid cone and is evenly distributed in the cross section of the reactor. The droplet size is 10-400 μm, preferably 10-200 μm, more preferably 20-100 μm;

[0084] 2) Passing phosgene through the cold phosgene tube 4, the molar ratio of phosgene to organic amine is 2-15, preferably 3-6, and the phosgene inlet temperature is -10-65°C. In the reactor, phosgene and the organic amine solution liquid mist in the step 1) come into reverse contact reaction to form formyl chloride and ami...

Embodiment 1

[0101] 1) The mass concentration of the chlorobenzene solution of toluene diamine (TDA) is 17%, the feed flow rate is 40kg / h, and the feed temperature is 50°C. It is sprayed into the reactor interior by the feed atomizing nozzle 1, and the spray angle is 60°. uniformly distributed across the reactor cross-section.

[0102] 2) Phosgene is fed into the cold phosgene pipe 4, the flow rate is about 35kg / h, and the inlet temperature is 20°C. In the reactor, the phosgene and the mist of the amine solution come into reverse contact, react rapidly and release heat, and the temperature of the cold phosgenation reaction section is about 90°C.

[0103] 3) The secondary phosgene feed pipe 5 is fed with phosgene, the flow rate is about 33kg / h, and the inlet temperature is 20°C. , step 2) in the droplet falling in the high temperature reverse further phosgenation reaction, this section is called high temperature phosgenation reaction section, the main reaction is phosgenation of amine hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com