Equipment for continuously preparing polyglycolic acid granules

A technology of polyglycolic acid and granules, which is applied in the direction of cleaning hollow objects, chemical instruments and methods, cleaning methods and utensils, etc., can solve the amplification effect, has no cold solidification granulation, and cannot be directly applied to continuous industrialized polyglycolic acid. Production equipment and other problems, to avoid hydrolysis degradation, uniform product size, and improve the overall processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

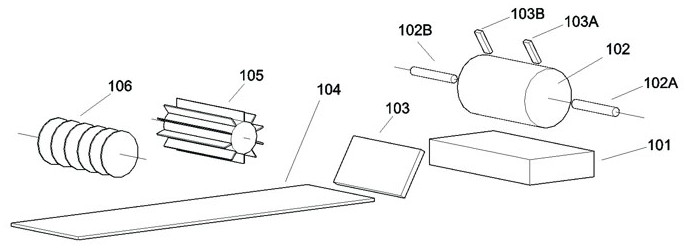

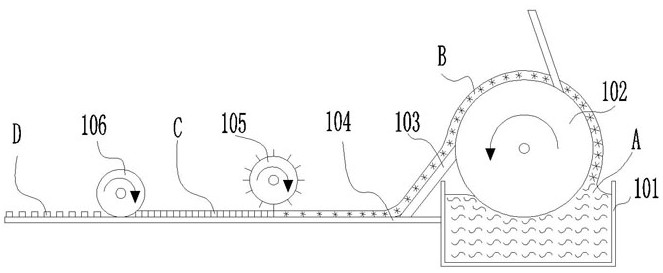

[0020] like figure 1 and figure 2 Shown is an equipment for continuously preparing finished polyglycolic acid pellets. The equipment has a nominal capacity of 100,000 tons / year and is equipped with a production line with a single-line nominal capacity of 100,000 tons / year. Among them, A represents polyglycolic acid melt, B represents polyglycolic acid flakes, C represents polyglycolic acid strips, and D represents polyglycolic acid pellets. In this embodiment, the drum cooler 102, scraper 103, first cutter 105, and second cutter 106 are arranged from right to left. The drum cooler 102 is placed in the molten material storage tank 101, and the drum is cooled and fixed A first scraper 103A and a second scraper 103B are respectively arranged above the device 102. One end of the scraper 103 is closely connected with the drum cooler 102, and the other end is connected with the bottom plate 104. The first cutter 105 and the second cutter 106 is fixedly arranged on the bottom plat...

Embodiment 2

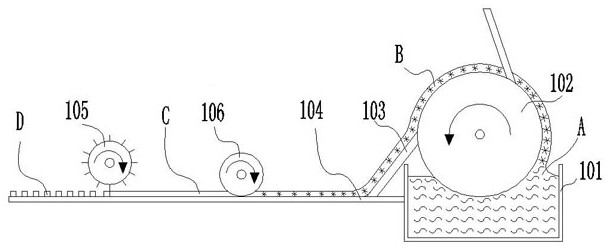

[0024] like figure 1 and image 3 Shown is an equipment for continuously preparing finished polyglycolic acid pellets. The equipment has a nominal capacity of 100,000 tons / year and is equipped with a production line with a single-line nominal capacity of 100,000 tons / year. Among them, A represents polyglycolic acid melt, B represents polyglycolic acid flakes, C represents polyglycolic acid strips, and D represents polyglycolic acid pellets. In this embodiment, the drum cooler 102, scraper 103, second cutter 106, and first cutter 105 are arranged from right to left. The drum cooler 102 is placed in the molten material storage tank 101, and the drum is cooled and fixed. A first scraper 103A and a second scraper 103B are respectively arranged above the device 102, one end of the scraper 103 is closely connected with the drum cooler 102, and the other end is connected with the bottom plate 104, the second cutter 106 and the first cutter 105 is fixedly arranged on the bottom plat...

Embodiment 3

[0028] The specific operation process is the same as in Example 1, except that the process parameters are changed. The process parameters of this embodiment after the change are as follows: the operating temperature of the molten material storage tank 101 is 245° C.; the outer surface of the drum cooler 102 and the scraper 103 After the outer surface and the outer surface of the bottom plate 104 are mirror polished, the roughness of the outer surface is 0.50 μm≦Ra≦0.60 μm; the outer wall below the drum cooler 102 is immersed in the molten polyglycolic acid molten material A liquid in the molten material storage tank 101 The height of the surface is 10.0-20.0mm.

[0029] Using the method described in this example, the melted polyglycolic acid material A is indirect heat exchanged with cooling water and then solidified into a polyglycolic acid sheet B, which is sequentially cut into polyglycolic acid strips C and polyglycolic acid pellets D, This avoids the hydrolytic degradatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com