Composition and method of manufacture of multi-layer tube having polyamide outer layer

A multi-layer pipe and polyamide technology, applied in the field of multi-layer pipe, can solve problems such as joint leakage, reduced blasting strength, and pipeline failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

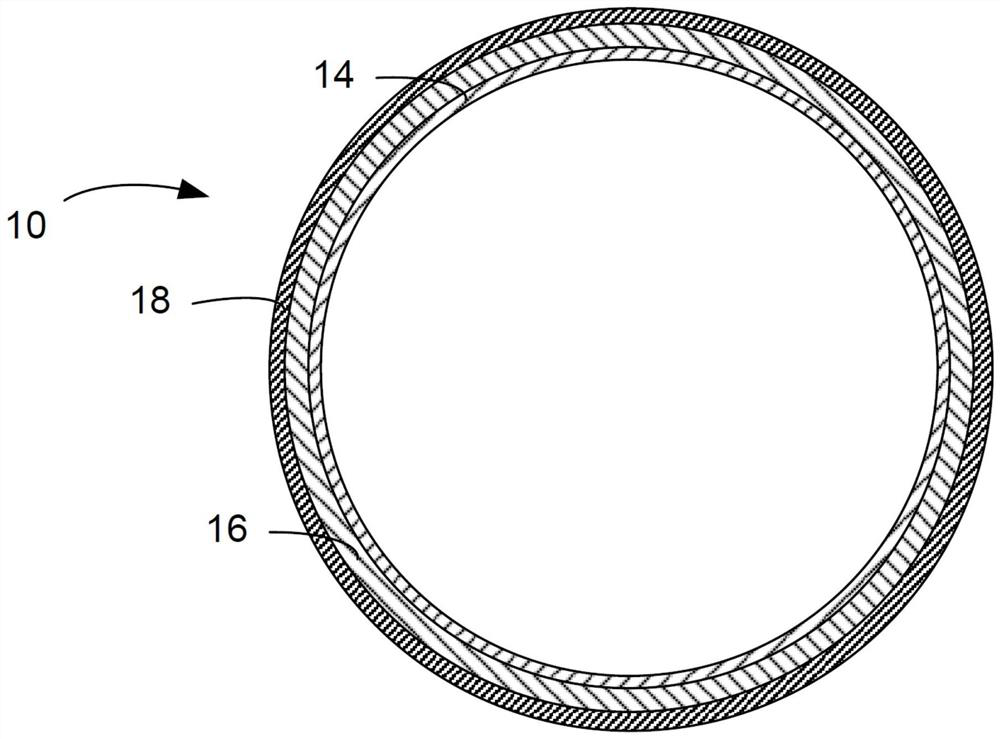

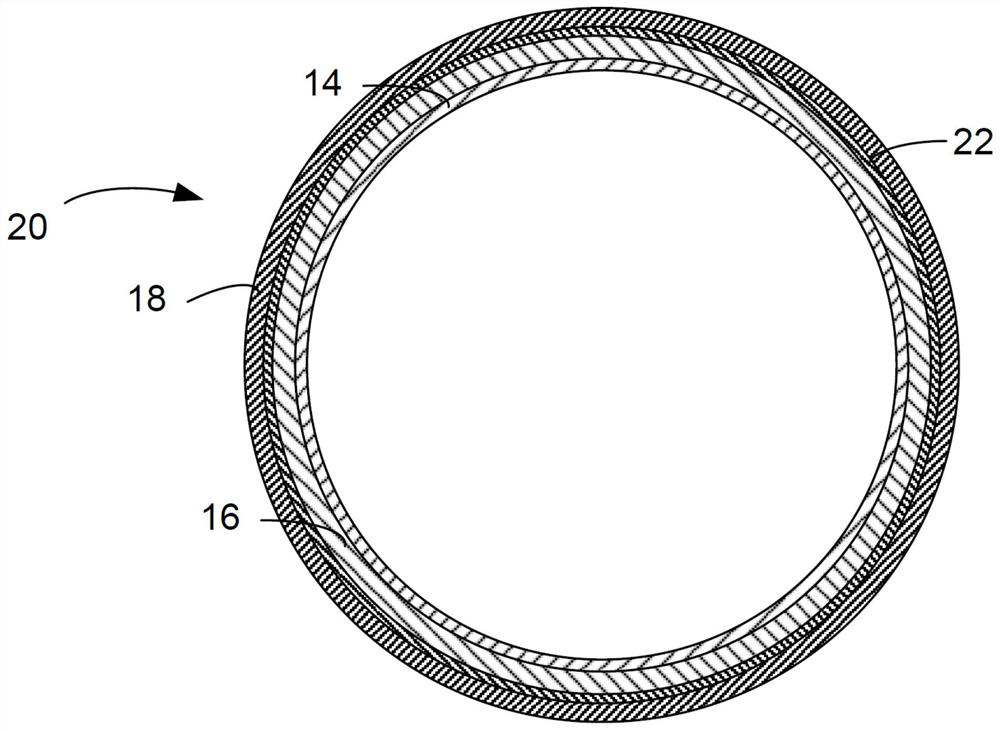

[0014] This disclosure is figure 1 and figure 2 The multilayer tube 10 is shown. Multilayer tubing is ideal for medium temperature coolant line applications, but can be used in other applications as well. Tube 10 has at least one inner or first layer 14 , at least one middle or second layer 16 and at least one third or outer layer 18 . The tube 10 may have a polyamide outer layer 18 , a polyolefin middle layer 16 and a thermoplastic elastomer inner layer 14 . The polyamide outer layer 18 provides sufficient mechanical strength and the polyolefin middle layer 16 protects the polyamide from contact with water from hydrolytic degradation. The present disclosure proposes a thermoplastic elastomer inner layer 14 to prevent creep stress cracking in the polyolefin intermediate layer 16 and to provide a superior seal with connectors or other tubing.

[0015] The multilayer tube 10 is preferably manufactured by coextruding thermoplastic materials simultaneously in a conventional c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com