System and method for industrially producing PGA product

A technology for products and melting materials, applied in the field of systems for producing degradable polyglycolide products, can solve the problems of accelerated polyglycolide hydrolysis and degradation, large loss of pellet products, and easy degradation reactions, and avoid hydrolysis. The effect of degradation, good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

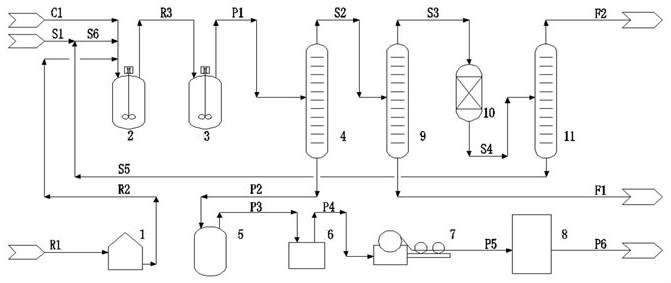

[0027] Such as figure 1 As shown in the schematic diagram of the process flow, the nominal capacity of the PGA industrial production plant is 100 thousand tons per year, and one production line is set up, and the nominal capacity of the single line is 100 thousand tons per year. Among them, R1 represents the glycolide raw material, R2 represents the glycolide raw material, R3 represents the glycolide intermediate material, C1 represents the catalyst, S1 represents the fresh solvent, S2 represents the solvent volatilized in the polymerization reactor, and S3 represents the treatment in the PGA devolatilizer The obtained solvent, S4 represents the solvent obtained by the solvent regenerator, S5 represents the circulating solvent, S6 represents the mixed solvent, P1 represents the reaction product, P2 represents the reaction product after the PGA devolatilizer, P3 represents the PGA powder, P4 represents the PGA Melt material, P5 means PGA pellets, P6 means PGA product, F1 means ...

Embodiment 2

[0032] The process flow is the same as in Example 1, except that the process parameters are changed. The changed process parameters of this embodiment are as follows: the catalyst C1 includes a main catalyst and a co-catalyst, wherein the main catalyst is a zinc organic compound, and the co-catalyst is tert-butanol , the mixed solvent S6 is ethanol; the polymerization reaction pressure of the first polymerization reactor 2 and the second polymerization reactor 3 is normal pressure, the polymerization reaction temperature is 60 ° C, the reaction residence time is 120 minutes, the main catalyst and glycolide The mass ratio of raw materials is 1.0:10000, the mass ratio of cocatalyst to main catalyst is 1.2:1, and the mass ratio of solvent to glycolide raw material is 4.0:1; the operating temperature of PGA crystallizer 5 is 15°C, and PGA melter 6 The operating temperature was 215°C.

[0033] Thus, this embodiment has achieved the technical goal of large-scale commercial continuou...

Embodiment 3

[0035] The process flow is the same as in Example 1, except that the process parameters are changed. The changed process parameters of this embodiment are as follows: the catalyst C1 includes a main catalyst and a co-catalyst, wherein the main catalyst is an aluminum organic compound, and the co-catalyst is isobutanol , the mixed solvent S6 is ethanol; the polymerization reaction pressure of the first polymerization reactor 2 and the second polymerization reactor 3 is normal pressure, the polymerization reaction temperature is 240 ° C, the reaction residence time is 10 minutes, the main catalyst and glycolide The mass ratio of raw materials is 9.0:10000, the mass ratio of cocatalyst to main catalyst is 8.0:1, and the mass ratio of solvent to glycolide raw material is 20.0:1; the operating temperature of PGA crystallizer 5 is 45°C, and PGA melter 6 The operating temperature is 245°C.

[0036] Thus, this embodiment realizes the technical goal of large-scale commercialized contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com