Automatic loading and unloading equipment and automatic cargo loading and unloading method

A technology of automatic loading and unloading and equipment, which is applied in the direction of loading/unloading, transportation and packaging, conveyor objects, etc. It can solve the problems of inability to dock with docks, etc., and achieve the effects of not being easily damaged, long service life, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

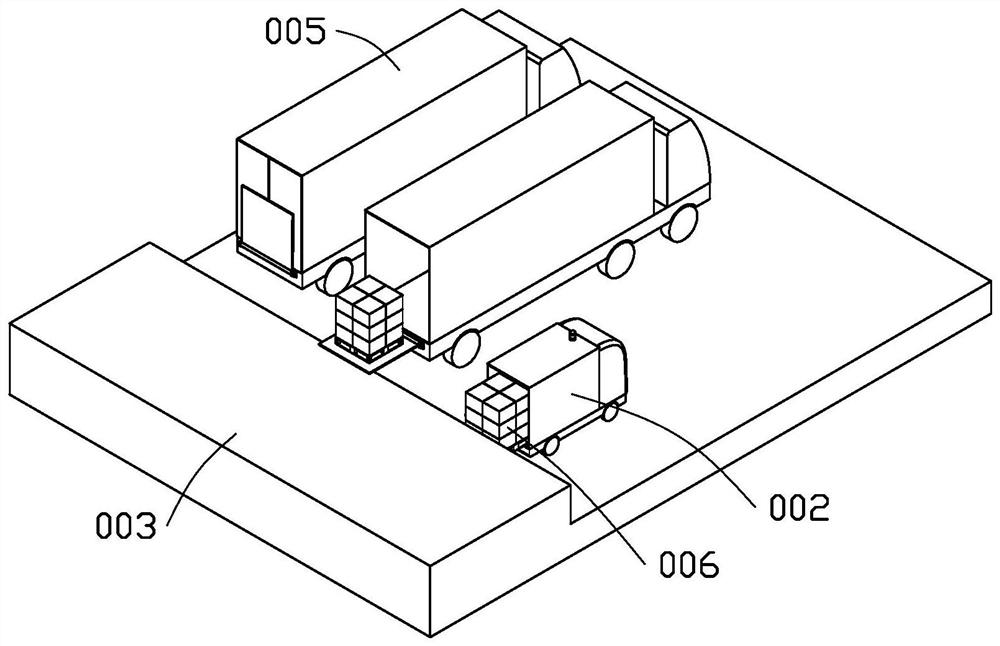

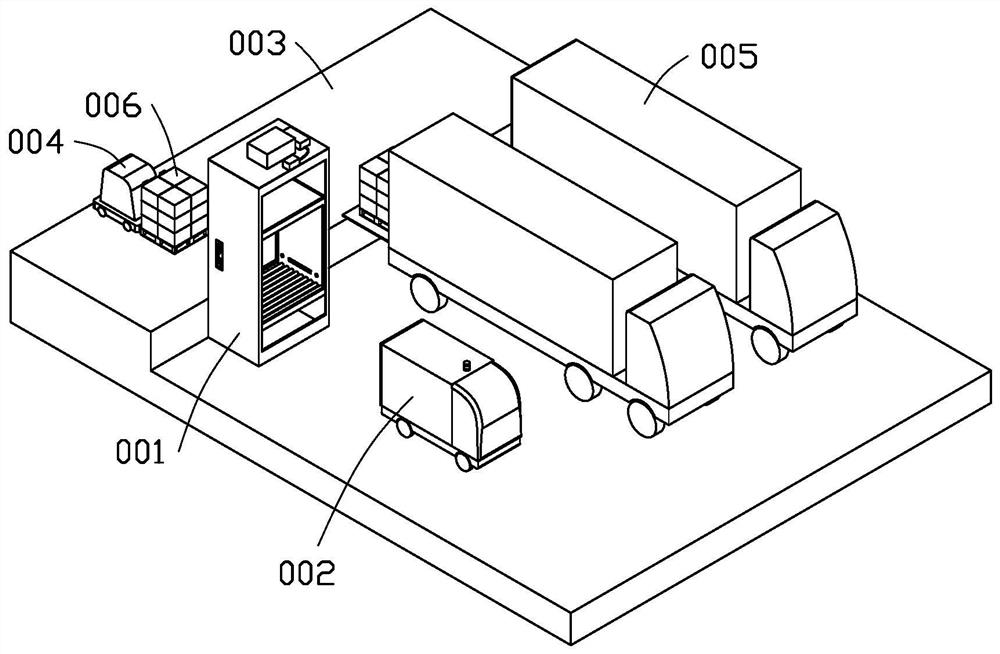

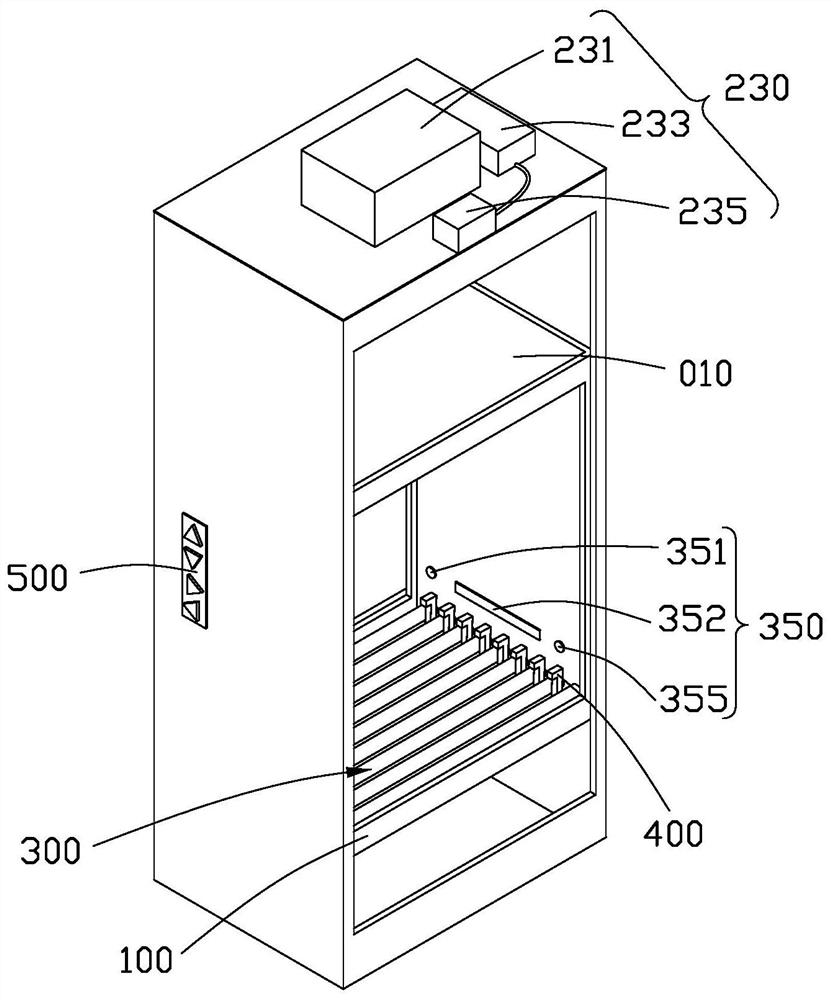

[0130] see figure 2 and image 3 , the first embodiment of the present application provides an automatic loading and unloading device 001, which is used for transferring goods 006 between unloading positions and loading positions with height differences such as wharf 003. This automatic loading and unloading device 001 includes a lifting plate 100 and a transmission device. The lifting plate 100 has a load-bearing surface 101 for carrying goods 006. The transmission device transmits the goods 006 on the load-bearing surface 101 between the unloading position and the loading position with a height difference. Displacement, the transmission device includes a lifting part 200 and a traverse part 300; the lifting part 200 includes an outer frame 210 and a lifting drive device 230, the lifting plate 100 is accommodated in the outer frame 210, and the driving end of the lifting drive device 230 drives the lifting plate 100 outside The inner frame 210 is raised and lowered, and the...

Embodiment 2

[0156] see Figure 15 , the second embodiment of the present application provides an automatic loading and unloading method, using the transportation device 002 and the automatic loading and unloading equipment 001 provided in Embodiment 1 to realize unloading of the cargo 006 on the wharf 003 and loading the cargo 006 into the transportation device 002 ,include:

[0157] S101 : The transportation device 002 initiates a docking command to the wireless communication unit 235 electrically connected to the lifting driving device 230 .

[0158] S102: The lifting drive device 230 drives the lifting plate 100 to rise to the height of the wharf 003.

[0159] S103: The wireless communication unit 235 sends an instruction to start loading to the transportation device 002 and the forklift 004.

[0160] S104: The forklift 004 sends the goods 006 on the wharf 003 to the carrying surface 101 and contacts the traverse unit 300, such as Figure 9 , Figure 10 and Figure 11 shown.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com