A self-heating methanol reforming hydrogen production micro-reactor with both sealing and disassembly

A technology of reforming reaction and reforming hydrogen production, which is applied in the fields of hydrogen, chemical instruments and methods, hydrogen/synthesis gas production, etc., and can solve the problems such as difficulty in ensuring the airtightness of microreactors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

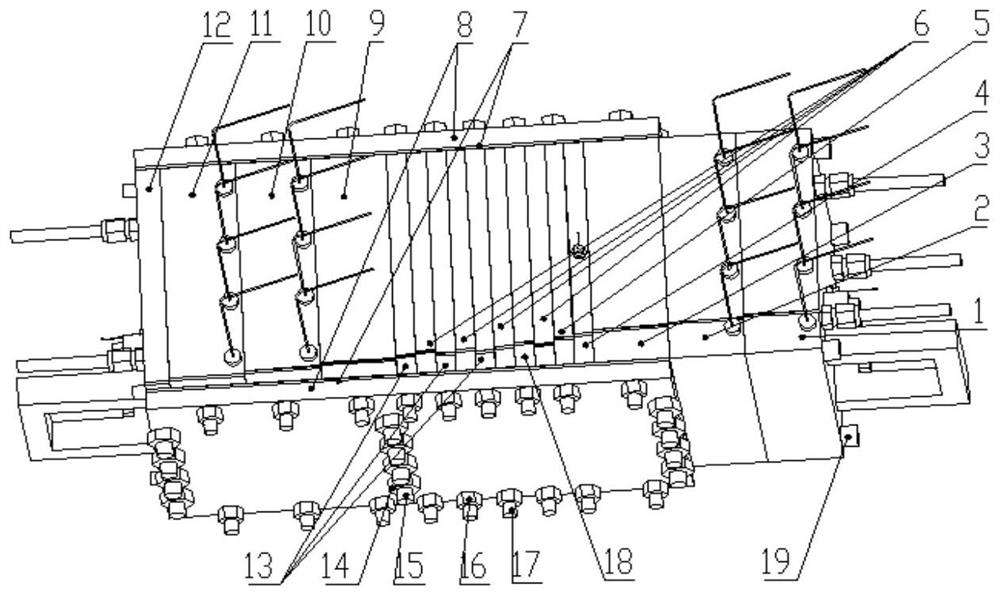

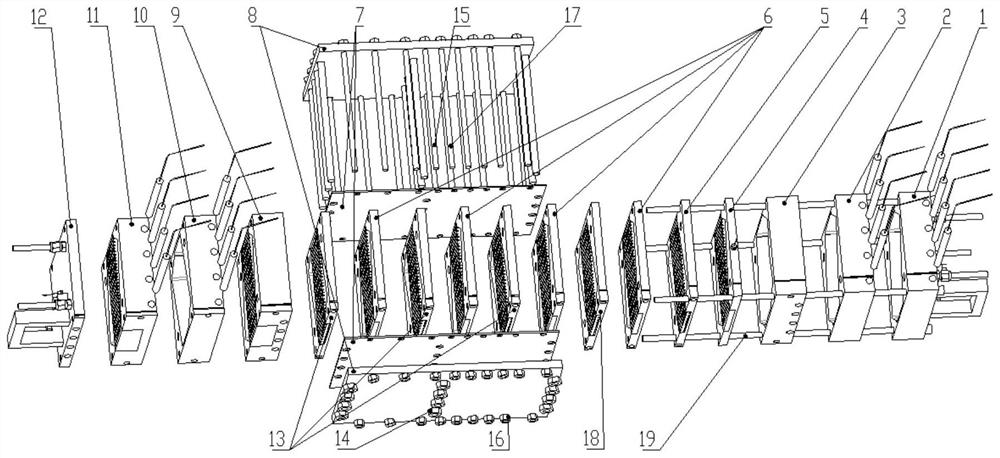

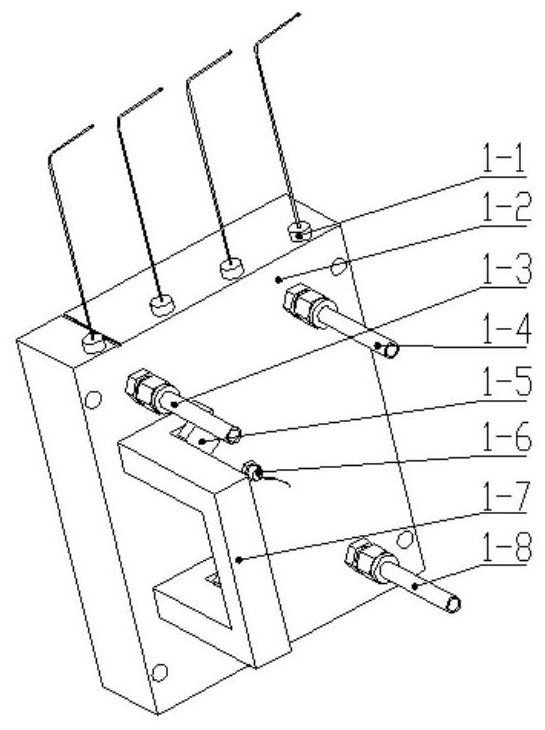

[0033] Such as Figure 1~2 As shown, a self-heating type methanol reforming hydrogen production micro-reactor with both sealing and disassembly properties of the present invention is mainly composed of an inlet combustion evaporation module (1), a combustion evaporation module (2), a combustion mixing chamber plate ( 3), combustion reaction module A (4), reforming reaction module A (5), combustion reaction module B (6), outlet cavity plate module (12), etc.; the cavity plates are: the entrance combustion evaporation cavity plate ( 1-2), combustion evaporation chamber plate (2-2), combustion mixing chamber plate (3), combustion reaction chamber plate A (4-2), reforming reaction chamber plate A (5-1), combustion reaction chamber plate B (6-1), reforming reaction chamber plate B (18-1), combustion reaction chamber plate B (6-1), reforming reaction chamber plate C (13-1), combustion reaction chamber plate B (6- 1), reforming reaction chamber plate C (13-1), combustion reaction ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com