Film-covered aerobic fermentation special multi-functional high-efficiency turning device

An aerobic fermentation and compost turning device technology, which is applied in the direction of fertilization device, application, bio-organic part treatment, etc., can solve the problem of losing the environmental protection advantages of film-covered aerobic fermentation technology, greenhouse gas and odor gas emissions, and the inability of materials to be directly processed Overturning and other issues to achieve the effect of improving space utilization efficiency, reducing hazards, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

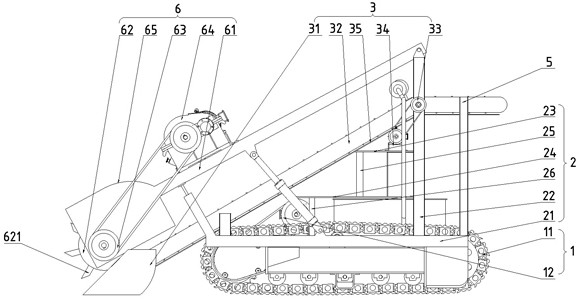

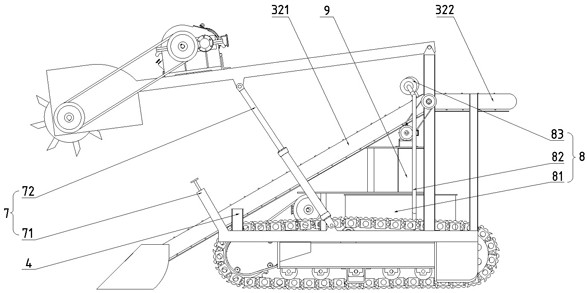

[0024] Such as figure 1 and figure 2As shown, the present invention provides a kind of film-covered aerobic fermentation special-purpose multifunctional high-efficiency turning device, comprising: traveling device 1, and traveling device 1 comprises crawler belt 11 and the crawler belt power unit 12 that is connected with crawler belt 11, and crawler belt power unit 12 uses Drive the crawler belt 11 to rotate to realize the walking and turning of the whole machine; the main body bracket 2, the main body bracket 2 includes two horizontal load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com