A kind of low carbonation washing steel with excellent formability and surface quality and production method

A technology of surface quality and formability, applied in the field of steel production, can solve problems such as poor thickness accuracy, rough surface, stamping cracking, etc., and achieve the effects of reducing production costs, high plastic strain ratio, and light aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

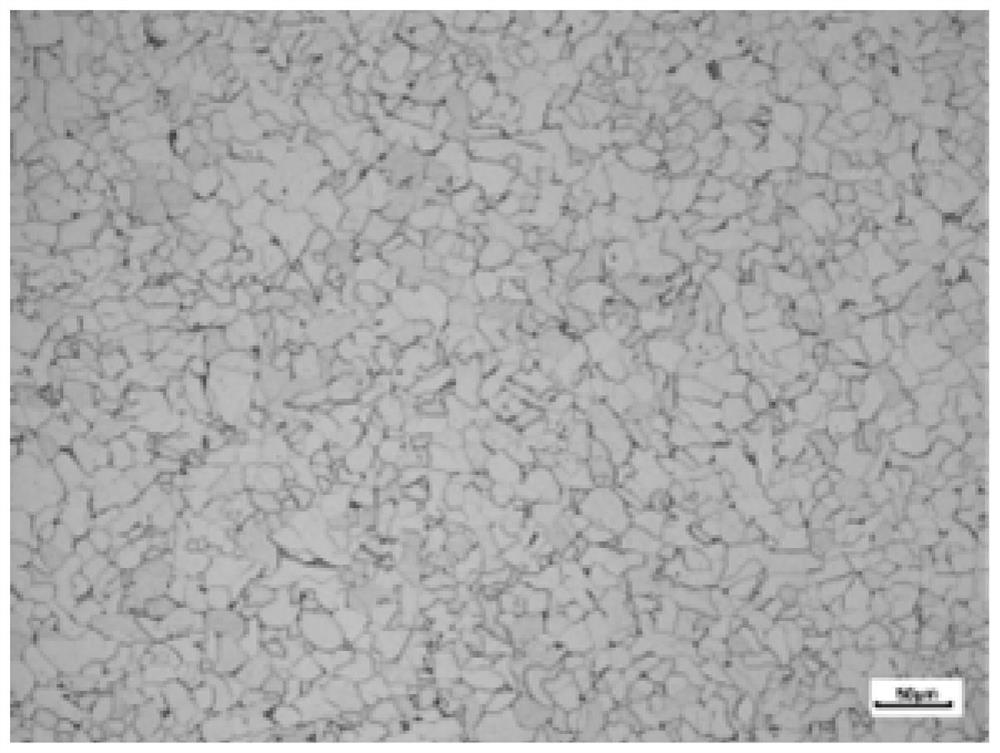

Image

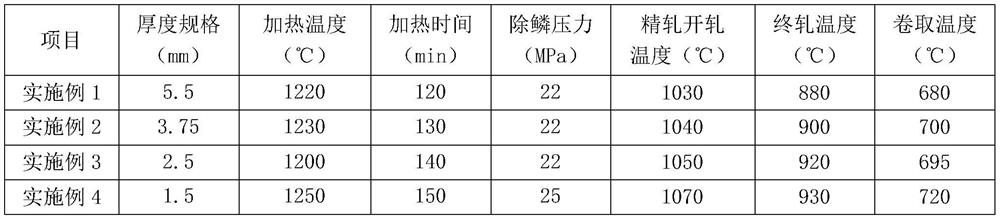

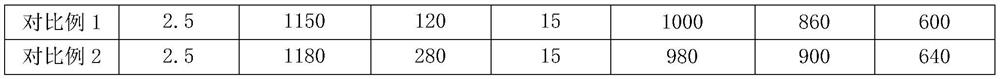

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0016] The composition design mass percentage of the low carbonation washed steel of the present invention is: C: 0.03-0.05%, Si: 0.035-0.08%, Mn: 0.1-0.3%, P≤0.015%, S≤0.008%, N≤0.005%, Alt : 0.020-0.045%, B: 0.001-0.003%, the rest is iron and unavoidable impurities. Where B / N: 0.7-1.4.

[0017] The compositional design is detailed as follows:

[0018] C is one of the main control elements of low-carbonated steel, which has an important influence on the structure and properties of low-carbon steel. If the C content is too high, the strength of the pickled steel plate will increase, the elongation will decrease, and its formability and weldability will deteriorate; but if the carbon content is less than 0.030%, it is necessary to increase the vacuum treatment process for decarburization and increase the cost. Therefore, the present invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com