Online monitoring method for fatigue crack damage propagation of sintered neodymium iron boron

A technology for fatigue damage and fatigue cracks, applied in the field of non-destructive testing, can solve the problems of high environmental requirements, high monitoring costs, and difficult application of optical instrument monitoring methods, and achieve the effects of low requirements, saving monitoring costs, and wide application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The stress energy increased in the step S4 can be expressed as:

[0058]

[0059] Among them, σ is the stress, r1, r2, r3 are the direction cosines of the stress action, α1, α2, α3 are the direction cosines of the magnetization intensity, λ 100 , lambda 111 is the magnetostriction coefficient;

[0060] The sintered NdFeB sample without loading fatigue load history is magnetostrictive and isotropic, then λ 100 =λ 111 =λ σ ; where λ σ is the magnetostriction coefficient under the stress σ, then the increased stress can be expressed as:

[0061]

[0062] Among them, θ is the angle between the stress direction and the magnetization vector direction;

[0063] Assuming that the stress is parallel to the direction of magnetization in the uniaxial tensile test, then there is cos 2 θ=1, then the stress energy is:

[0064]

[0065] According to the energy balance theory based on the basic theory of ferromagnetism, in the geomagnetic field environment where the ma...

Embodiment 2

[0073] The electromagnetic constitutive relation under the air medium obtained in step S5 during the on-line monitoring of fatigue damage is expressed as:

[0074] B=μ 0 H (7)

[0075] Among them, μ σ is the vacuum permeability, B is the magnetic induction of the earth's magnetic field;

[0076] The electromagnetic constitutive relation of a ferromagnetic medium in a magnetic field environment is:

[0077]

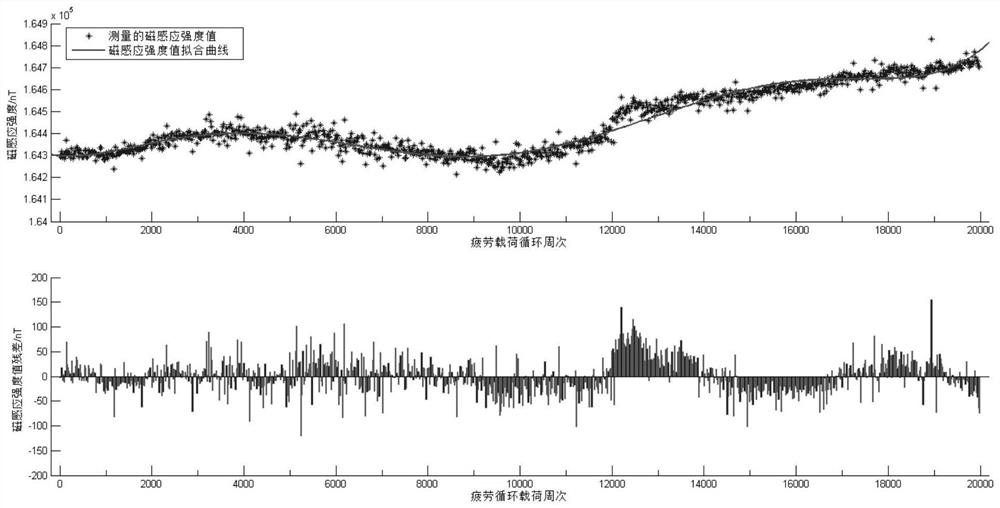

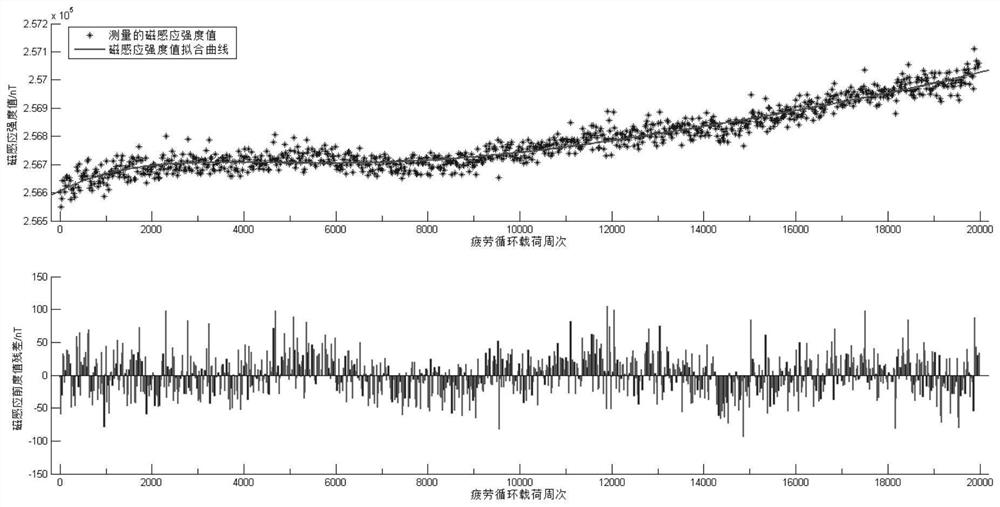

[0078] Among them, M(H, σ) is the magnetization change of sintered NdFeB under the action of force-magnetic coupling, and the magnetic induction value B of sintered NdFeB T Analysis of the variation of sintered NdFeB relative permeability μ σ With the evolution process of fatigue damage, the online monitoring of the fatigue damage expansion process of sintered NdFeB is realized.

Embodiment 3

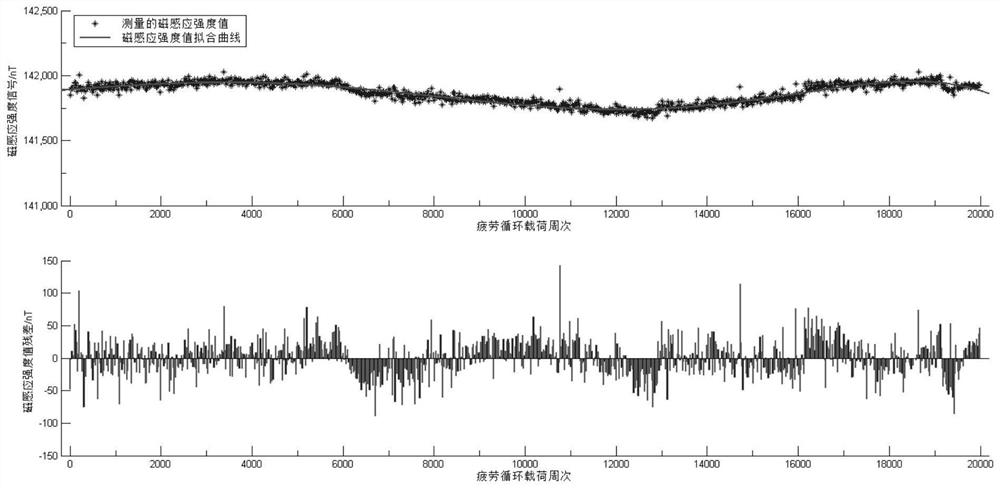

[0080] The judgment phenomenon of fatigue damage accumulation and fatigue fracture in the step S7 is as follows: when the residual value of magnetic induction fluctuates up and down in a small range, it indicates that it is in the process of fatigue damage accumulation; when the residual value of magnetic induction has an obvious upward trend, It shows that fatigue fracture occurs, and after the fatigue fracture behavior ends, the residual value of magnetic induction intensity shows a negative growth phenomenon, and the magnetic induction intensity value drops significantly. is caused by stress relief due to fatigue fracture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com