Polymer composite solid electrolyte, preparation method thereof and lithium ion battery

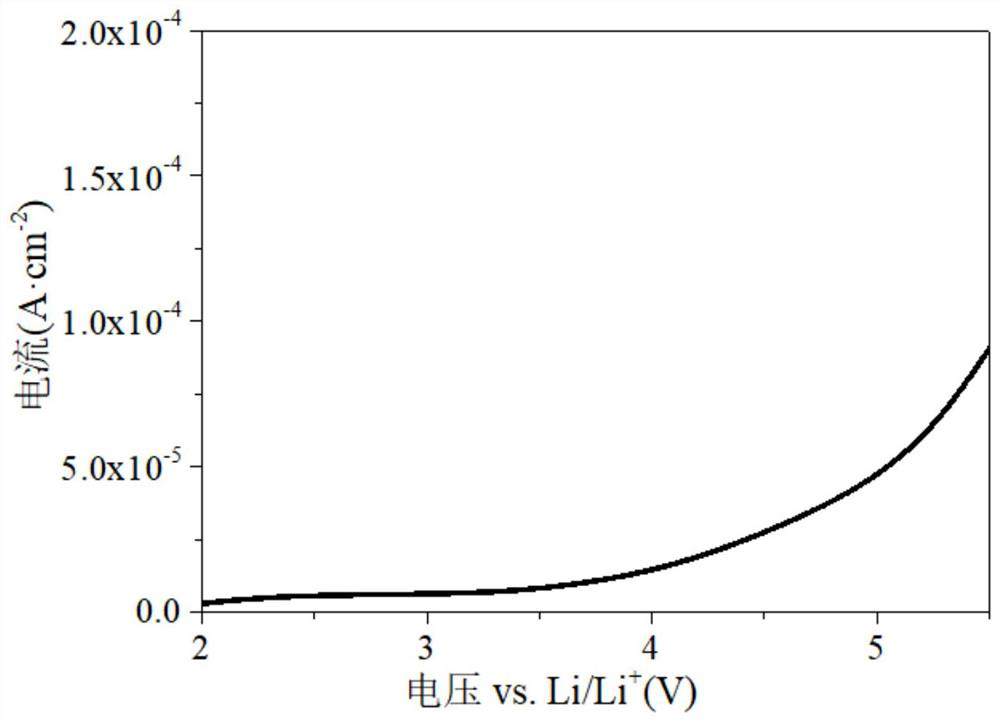

A solid electrolyte and polymer technology, applied in solid electrolytes, electrolytes, non-aqueous electrolytes, etc., can solve the problems of complex preparation methods of composite solid electrolytes, inability to fully utilize inorganic electrolytes, etc., to inhibit the growth of lithium dendrites and achieve high mechanical Strength, the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

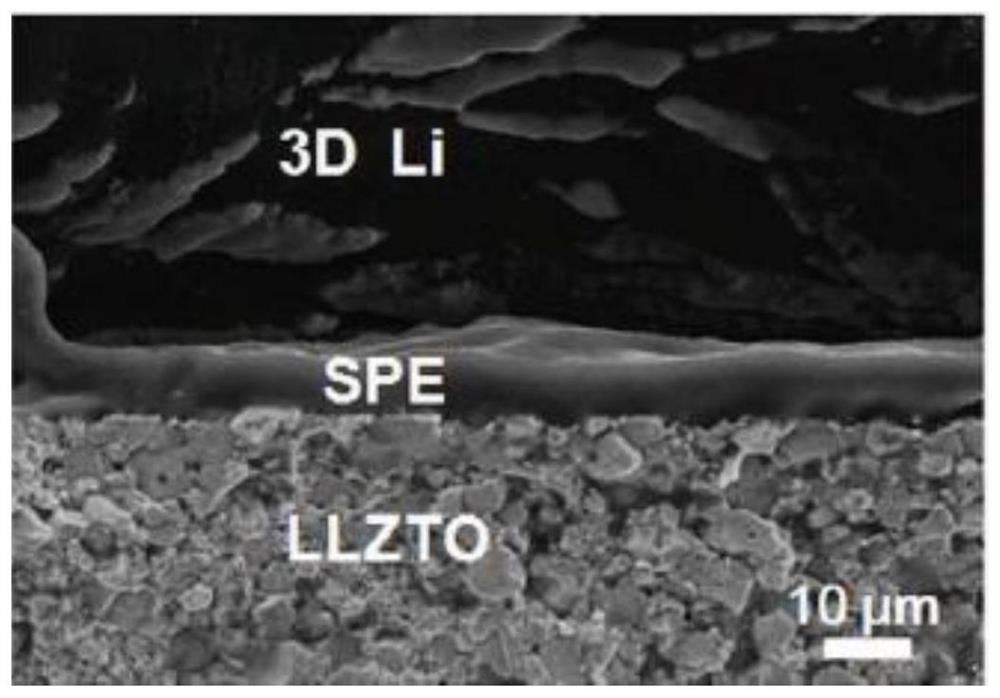

[0034] In another typical embodiment of the present application, a method for preparing any one of the above-mentioned polymer composite solid electrolytes is provided, the preparation method comprising: step S1, preparing a dispersion liquid in which polymers and lithium salts are dispersed; Step S2, disposing the dispersion liquid on the surface of the inorganic solid electrolyte layer, and removing the solvent in the dispersion liquid to obtain a polymer composite solid electrolyte.

[0035] The above preparation method does not require complex mixing process and molding means, is simple to operate and easy to implement, and is beneficial to industrial popularization and application.

[0036] In one embodiment, in order to improve the uniformity of dispersion of the polymer and the lithium salt, the above-mentioned step S1 preferably includes: step S11, dispersing the polymer in a solvent to form a polymer solution; step S12, dissolving the lithium salt in the polymer A dis...

Embodiment 1

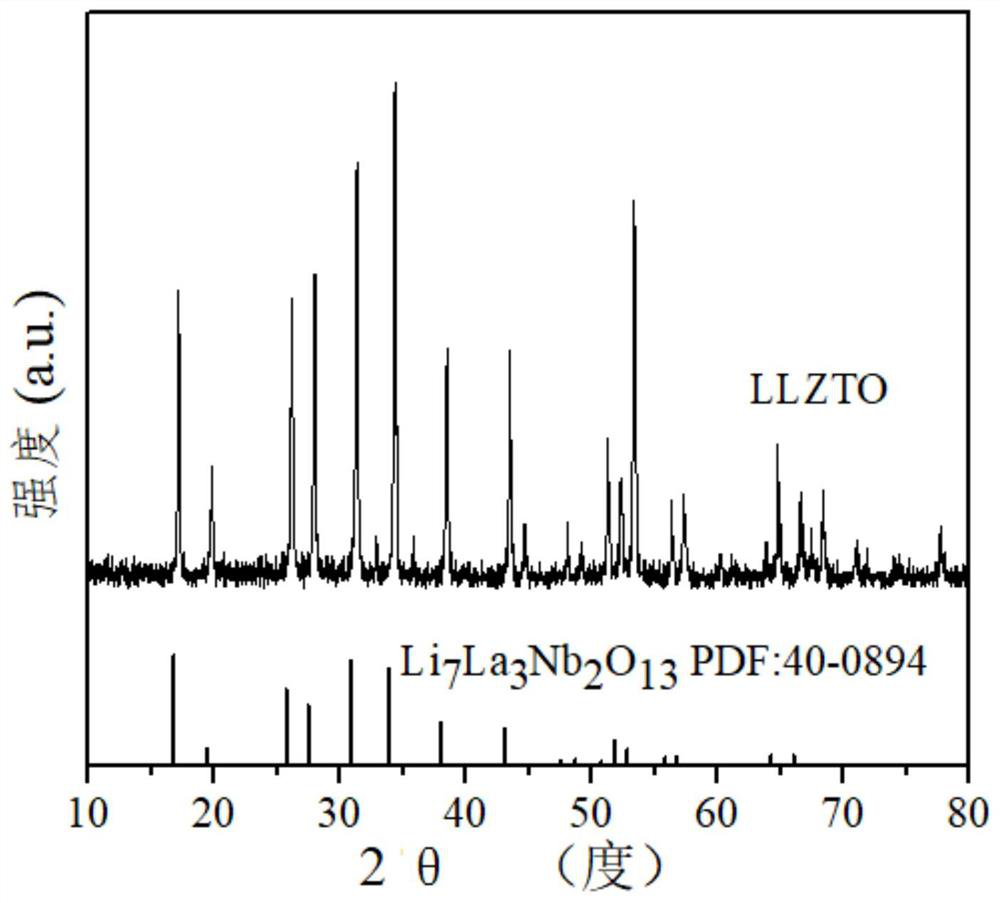

[0048] Mix 1g of polyurethane (TPU1190 from Yantai Wanhua) with 5.67g of N,N-dimethylformamide (DMF), heat to 60°C, and stir at 800rpm for 60min to fully dissolve to obtain a polyurethane solution. Subsequently, the above polyurethane solution was transferred to a glove box, maintained at 60°C, and 0.6 g of bistrifluoromethanesulfonimide lithium salt was added, and stirred at a speed of 800 rpm for 60 min to achieve full dissolution to obtain a dispersion. The dispersion liquid was uniformly drop-coated on one side of the prepared LLZTO sheet with a thickness of about 200 μm, and vacuum-dried (60°C, -0.1MPa) to obtain a polymer composite solid electrolyte sheet LLZTO-PU.

Embodiment 2

[0050] 1 g of polyurethane was mixed with 5.67 g of N,N-dimethylformamide (DMF), heated to 60° C., and stirred at a speed of 800 rpm for 60 min to fully dissolve to obtain a polyurethane solution. Subsequently, the above polyurethane solution was transferred to a glove box, maintained at 60°C, and 1 g of bistrifluoromethanesulfonimide lithium salt was added, and stirred at a speed of 1000 rpm for 80 min to achieve full dissolution to obtain a dispersion. The dispersion liquid was uniformly drop-coated on one side of the prepared LLZTO sheet with a thickness of about 200 μm, and vacuum-dried (60°C, -0.1MPa) to obtain a polymer composite solid electrolyte sheet LLZTO-PU.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com