Workpiece handling apparatus and method for batch processing planar workpieces

A technology for plate-shaped workpieces and operating equipment, which is applied in the destacking of objects, metal processing, and tool manufacturing, and can solve problems such as the efficiency limitation of processing machines and achieve low-complexity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

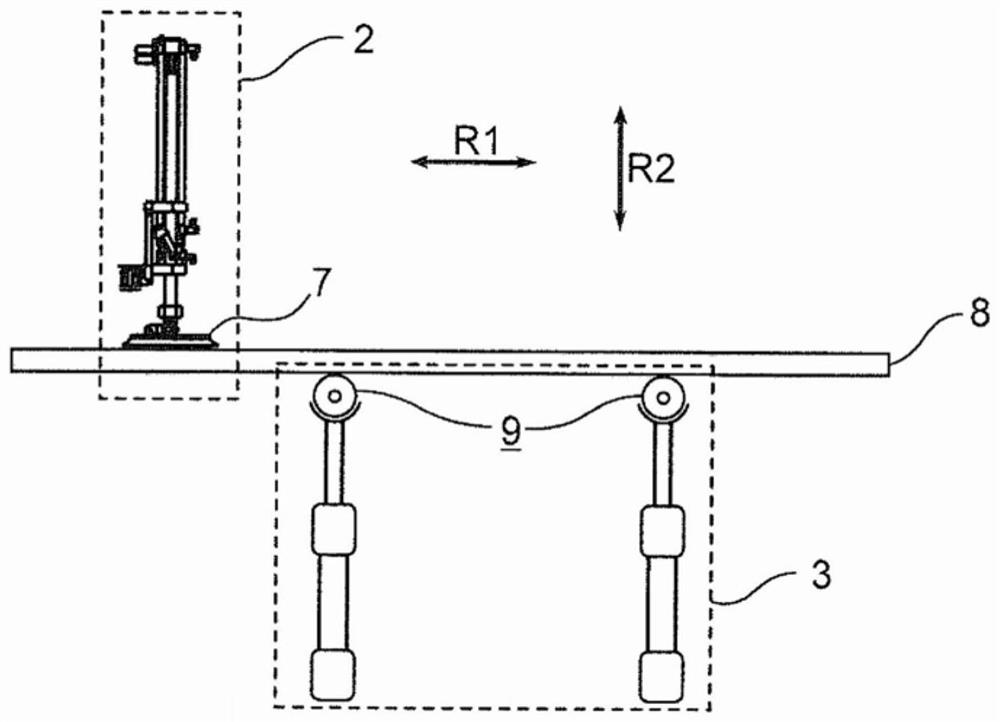

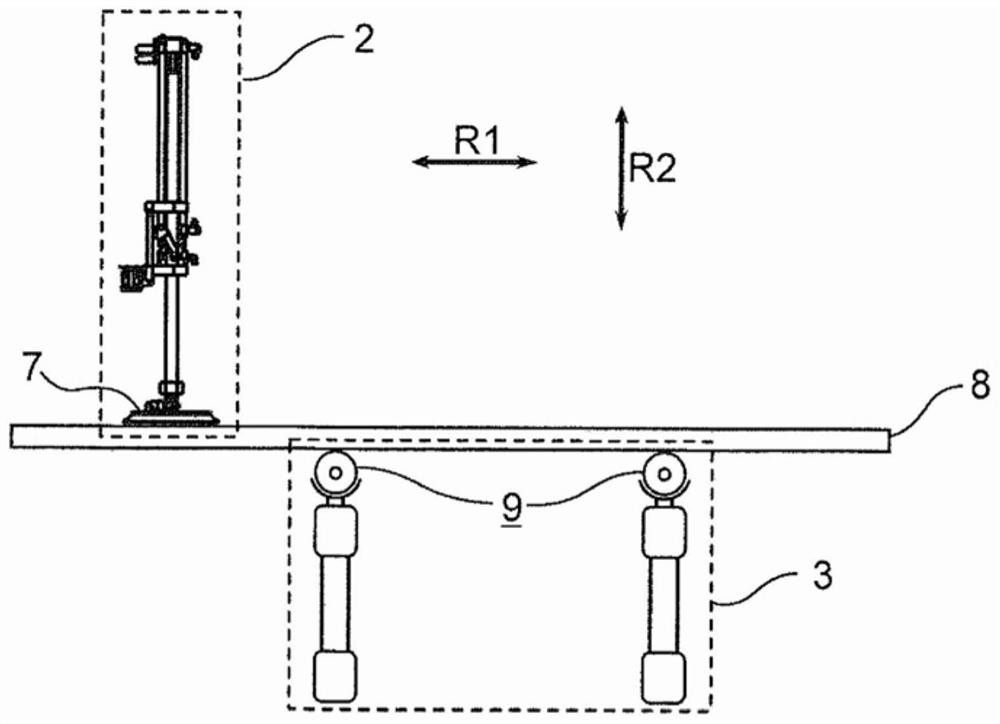

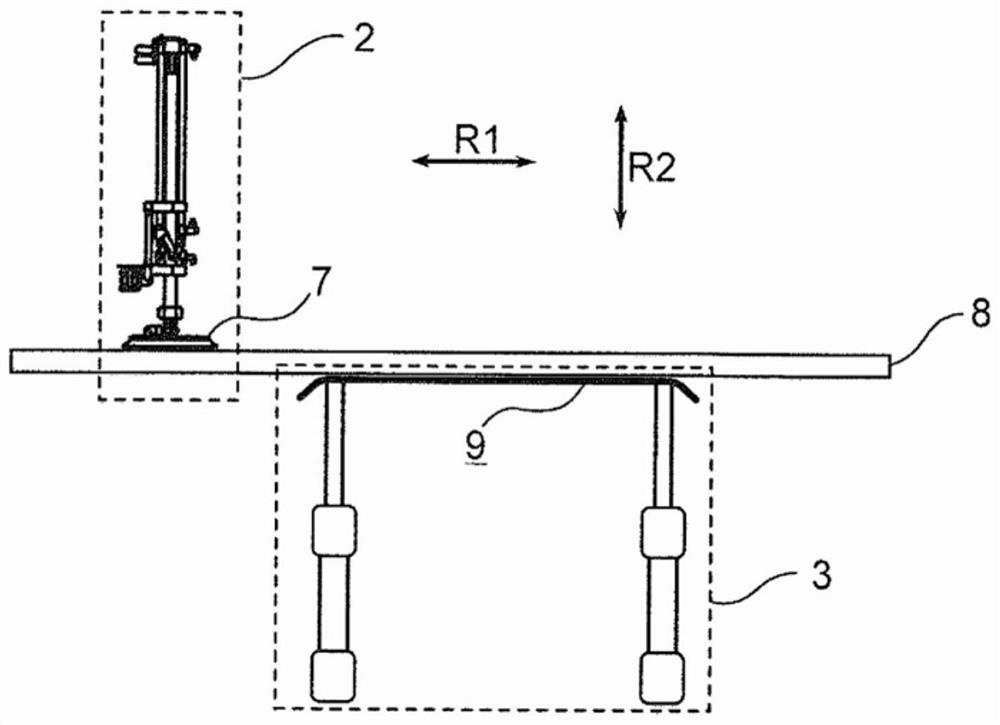

[0069] exist figure 1 A first preferred embodiment of the workpiece handling device 1 according to the invention is shown in a first state. The workpiece handling device can be used for handling plate-shaped workpieces 8 , such as solid wood boards or chipboards, and generally comprises a lifting unit 3 and a gripping unit 2 . The gripping unit 2 is set up to perform a displacement movement parallel to a first direction R1 , wherein, in the present case, the direction R1 extends linearly and horizontally.

[0070] The gripping unit 2 comprises a workpiece receptacle 7 which is designed as a suction gripper. In the state shown, the suction gripper is non-positively connected to the plate-like workpiece 8 . However, the suction gripper is designed such that it is also possible to disconnect it. Furthermore, the gripping unit 2 is designed such that the suction gripper can be moved parallel to the second direction R2 by means of a pneumatically or possibly hydraulically actuat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com