Novel compositions for bitterants

A composition and polymer technology, applied in applications, biocides, animal repellents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

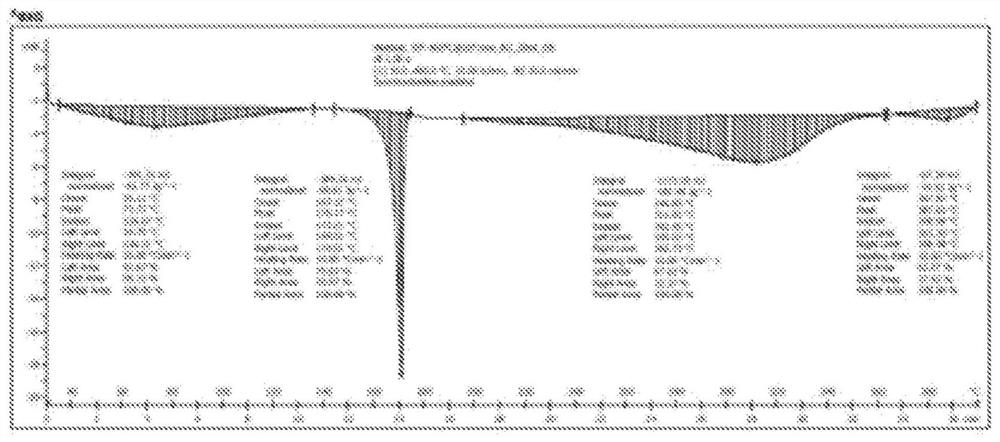

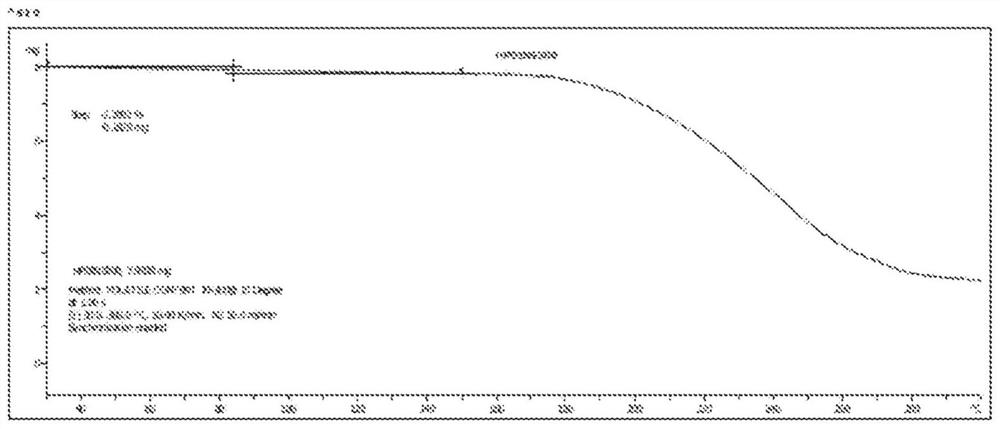

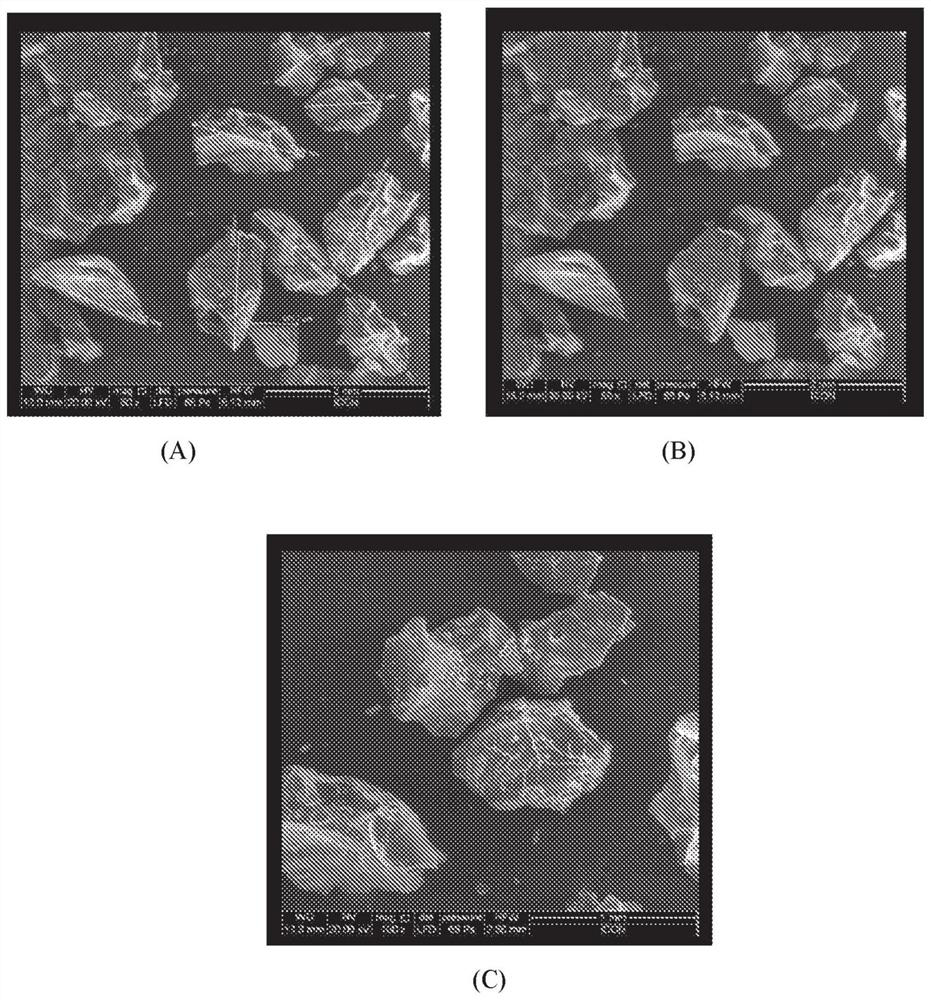

[0076] Example 1: Synthesis of Homopolymers of Poly(4-vinylpyridine) (PVP)

[0077]To boiling methanol (50 mL) drawn from a 250 mL three-necked flask equipped with a condenser and dropping funnel, a solution of 4-vinylpyridine (40 g) and AIBN (1 g) was added dropwise over 1 hour with stirring. The flask was maintained at 65°C to 70°C for an additional 3 hours. The solution was concentrated to half its volume under reduced pressure on a rotary evaporator at 65 °C. The solution was cooled to room temperature and gradually added to diethyl ether (100 mL) with stirring to precipitate a polymer. The polymer was washed 3-4 times with diethyl ether to remove traces of unreacted 4-VP. The polymer appeared as a pink powdery material.

Embodiment 2

[0079] Synthesis of poly(4-vinylpyridine) (PVP) homopolymer and 300 wt / wt% (relative In situ entrapment / blending of denatonium benzoate by weight of 4-VP .

[0080] Into a 250 mL glass kettle equipped with a condenser, dropping funnel and mechanical stirrer was added 60 g of denatonium benzoate and 60 mL of methanol. The reaction mass was heated to 65°C-70°C with stirring and held for 30 minutes. To the above clear solution was slowly added a mixture of 4-vinylpyridine (20 g) and AIBN (0.5 g) while stirring for 1 hour. After addition of the mixture, the reaction mass was maintained at the same temperature for an additional 3 hours. The hot reaction mass was then transferred to a petri dish and evaporated at room temperature (25°C-30°C) followed by vacuum evaporation at 50°C to obtain the DB-PVP blend mass. 73 g of polymer are obtained; product colour: dark brown. The polymer has a bitter taste.

Embodiment 3

[0082] Synthesis of poly(4-vinylpyridine) (PVP) homopolymer and 100 wt / wt% (relative In situ blending of DB in 4-VP by weight .

[0083] Into a 250 mL glass kettle equipped with a condenser, dropping funnel and mechanical stirrer was added 20 g of denatonium benzoate and 60 mL of methanol. The reaction mass was heated to 70°C with stirring and held for 30 minutes. To the above clear solution was slowly added a mixture of 4-vinylpyridine (20 g) and AIBN (0.5 g) while stirring for 1 hour. After the mixture was added, the reaction mass was maintained at the same temperature for an additional 3.0 hours. The hot reaction mass was then transferred to a petri dish and evaporated at room temperature (25°C-30°C) followed by vacuum evaporation at 50°C to obtain the DB-PVP blend mass. The powder is then stored in a container at room temperature. 38 g of polymer matrix are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com