Bridge protective guard metallic paint raw material production equipment

A technology for production equipment and guardrails, which is applied in the field of raw material production equipment for metal paint for bridge guardrails. It can solve the problems of increasing the hardness of the metal paint, sticking in the mixing tank, and being difficult to clean, and achieve the effect of increasing the vibration force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

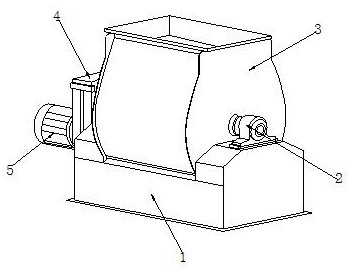

[0026] as attached figure 1 To attach Figure 4 Shown:

[0027] The invention provides a kind of raw material production equipment for metal paint of bridge guardrail, its structure includes base 1, runner 2, mixing bucket 3, linkage box 4, motor 5, described linkage box 4 is connected with mixing bucket 3, described The runner 2 is fixed on the upper right end of the base 1, and the motor 5 is fixed on the left end of the linkage box 4 for transmission cooperation.

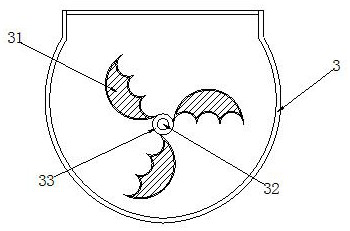

[0028] Wherein, the mixing bucket 3 is provided with a knife rest 31, a rotating column 32, and a support ring 33, the knife rest 31 is fixed on the outer end of the rotating column 32 for rotational cooperation, and the support ring 33 is connected with the rotating column 32, The knife rest 31 is divided into four and distributed in parallel, and the lower end of the knife rest 31 is distributed in three semicircles, which is better for stirring evenly.

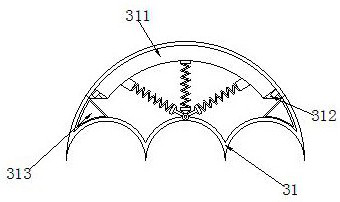

[0029] Wherein, the said tool holder 31 is provided w...

Embodiment 2

[0034] as attached Figure 5 To attach Figure 7 Shown:

[0035] The present invention provides a kind of raw material production equipment for metal paint of bridge guardrail. The rolling ball a2 is provided with a pulley a21, a gravity block a22, a support block a23, and a connecting plate a24. The pulley a21 is connected with the support block a23. The connecting plate a24 is connected with the support block a23, the gravity block a22 is fixed on the upper and lower ends of the support block a23, the pulley a21 is semicircularly distributed on the four sides, and the gravity block a22 is fixed on the support block in the form of a cube. The lower left corner of the block a23 and the upper right corner are diagonally distributed to increase the scrolling speed.

[0036] Wherein, the gravity block a22 is provided with a magnetic block b1, a slider b2, a slide rail b3, a fixed plate b4, and a block b5, the magnetic block b1 is fixed on the left and right ends of the slide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com