Numerical control rotary workbench for laser processing

A technology of rotary worktable and worktable, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of unsatisfactory application status of worktable motion accuracy and carrying capacity, limited supporting carrying capacity, difficult maintenance and adjustment, etc. , to achieve the effect of low cost, improved bearing capacity, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

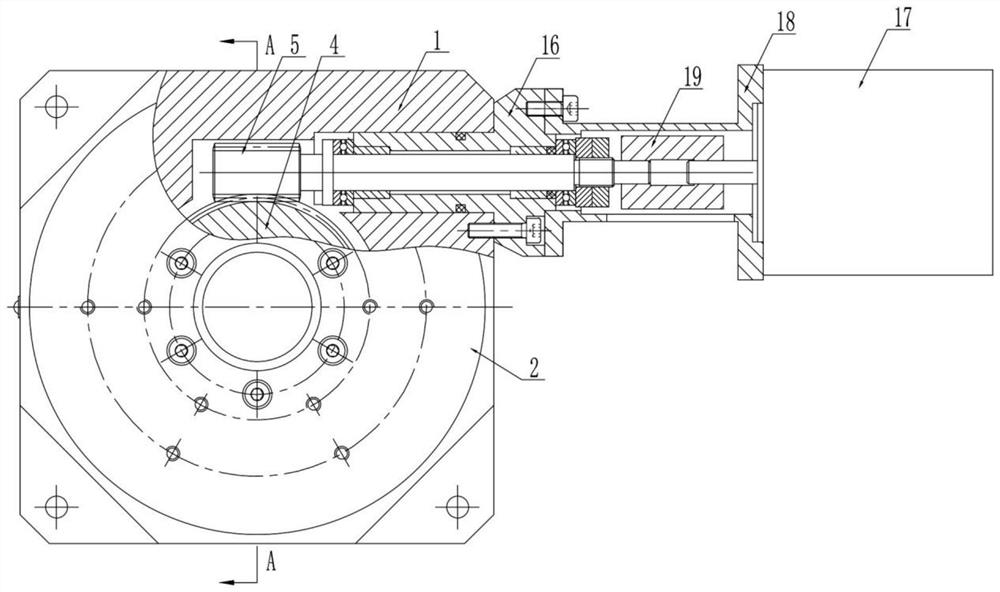

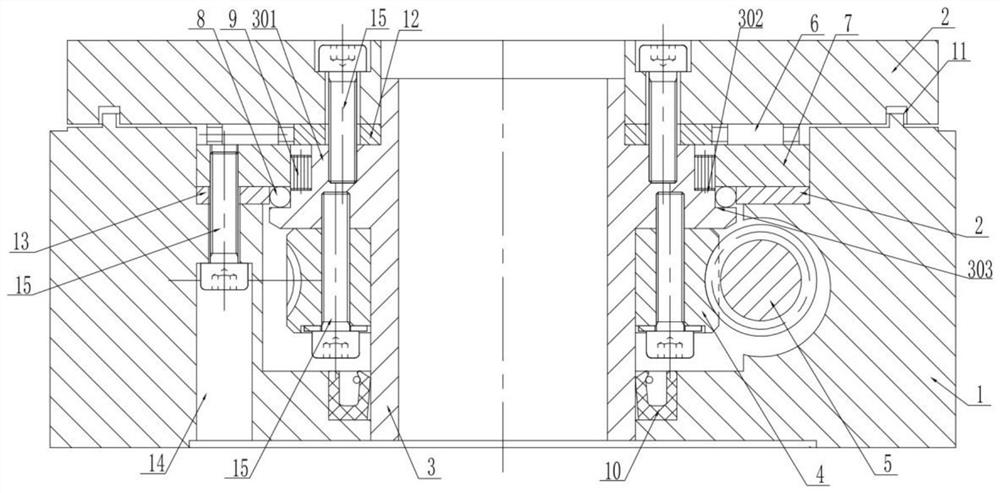

[0031] Such as figure 1 and figure 2 As shown, a CNC rotary table for laser processing includes a table base 1, a table 2 arranged on the table base, a rotating shaft 3, a support ring 7, a plurality of support balls 8 and a plurality of needle rollers 9. The inside of the rotating shaft is provided with a through hole, and the rotating shaft rotates under the action of the driving mechanism. The driving mechanism includes a driving motor, a worm 5 and a worm wheel 4, and the worm wheel is installed on the rotating shaft. The worm is rotatably mounted on the base of the workbench, one end of the worm is connected to the output shaft of the drive motor, and the other end is engaged with the worm wheel;

[0032] The base of the worktable is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com