Geometric error modeling and separating method for five-axis AC rotating and swinging head gantry machine tool

A technology of geometric error and gantry machine tool, which is used in metal processing mechanical parts, measuring/indicating equipment, metal processing equipment, etc., can solve the geometric error of five-axis AC swing head gantry machine tool, etc., to improve measurement efficiency and reduce measurement. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0034] A geometric error modeling and separation method of a five-axis AC rotary head gantry machine tool, comprising the following steps:

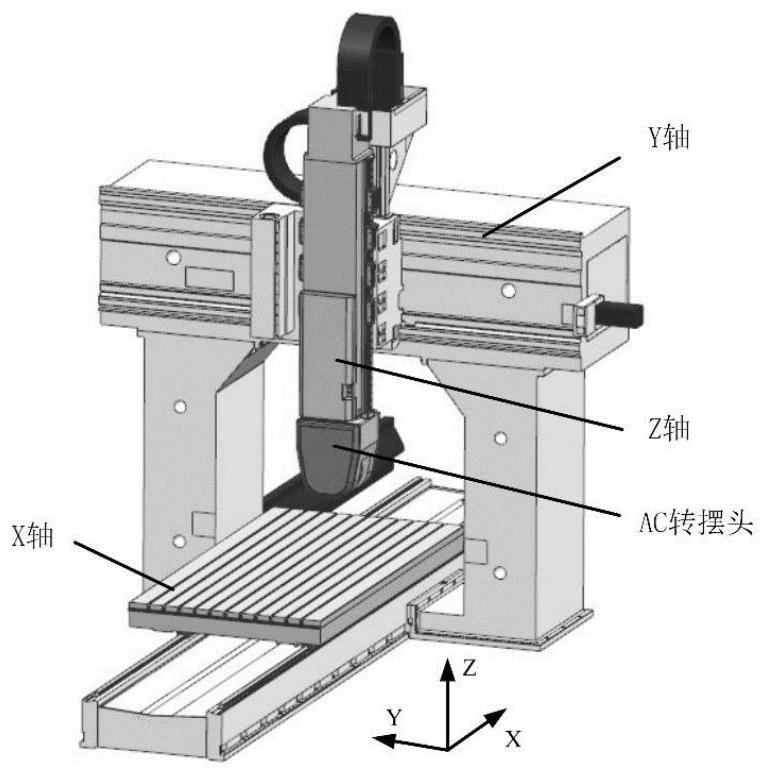

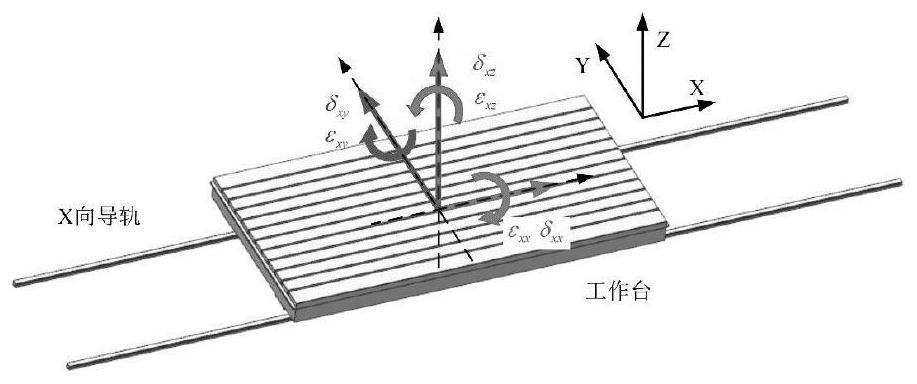

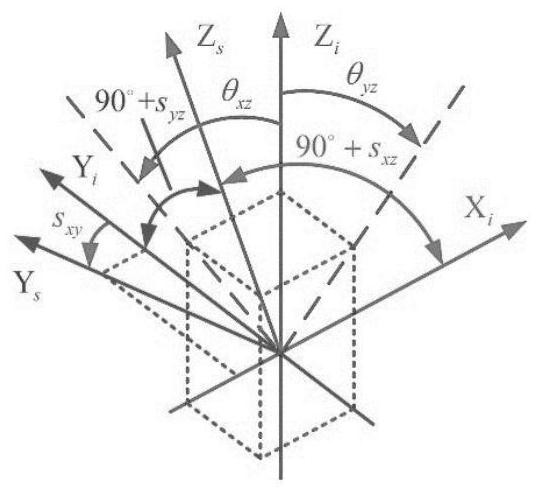

[0035] Step 1) Refer to figure 1 According to the structure and transmission form of the five-axis AC rotary head gantry machine tool, according to the multi-body kinematics theory and the homogeneous coordinate transformation theory, the relative motion conversion matrix between axes is obtained, and the kinematics of the machine tool from the tool coordinate system to the workpiece coordinate system is established Model;

[0036] 1.1) Establish the kinematics model of the five-axis machine tool:

[0037] According to the relative motion relationship between the machine tool axes, the machine tool is defined as XFYZCA type, the letters X, Y, Z, A, and C represent the linear axis and the rotary axis respectively, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com