Cooling system of thermal forming hydraulic machine

A technology of cooling system and hydraulic press, applied in the direction of press, fluid pressure actuation system components, punching machine, etc., can solve the problems of high temperature heat conduction, high temperature overflow, equipment shutdown and cooling, etc., to achieve compact overall layout and stable cooling effect. , the effect of high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

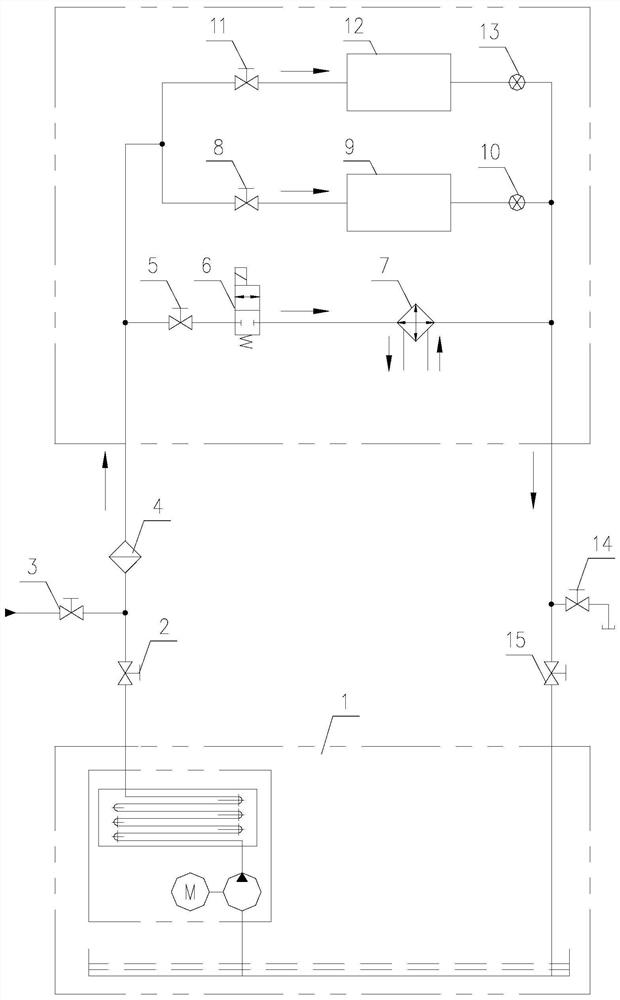

[0029] The cooling system of the thermoforming hydraulic press, the cooling system of the thermoforming hydraulic press includes: chiller 1, gate valve A2, gate valve B3, Y-type filter 4, gate valve C5, electromagnetic water valve 6, cooler 7, gate valve D8, lower platform Cold water plate 9, flow temperature sensor A10, gate valve E11, upper platform cold water plate 12, flow temperature sensor B13, gate valve F14, gate valve G15;

[0030] The gate valve E, the upper platform cold water plate and the flow temperature sensor B are serially connected in series to form a branch A; the gate valve D, the lower platform cold water plate and the flow temperature sensor A are connected in series to form a branch B; the gate valve C, electromagnetic The water valve and the cooler are connected in series in sequence to form a branch C. The branch A, branch B and branch C are connected in parallel and then connected in series with gate valve G, water chiller, gate valve A and Y-type filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com