Method for reducing ethyl acetate in white spirit

A technology for medium ethyl acetate and liquor, which is applied in the preparation of alcoholic beverages, can solve the problems of high energy consumption, poor wine quality, and large loss of alcohol substances, and achieves low energy consumption, good effect and short production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

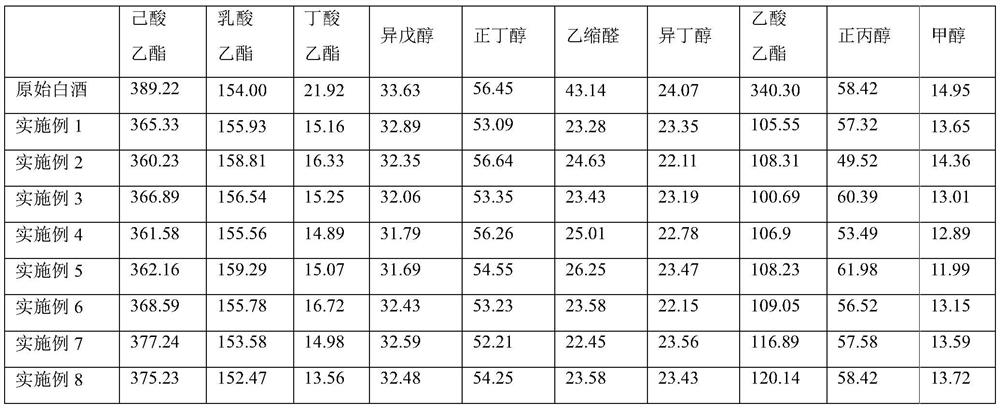

Embodiment 1

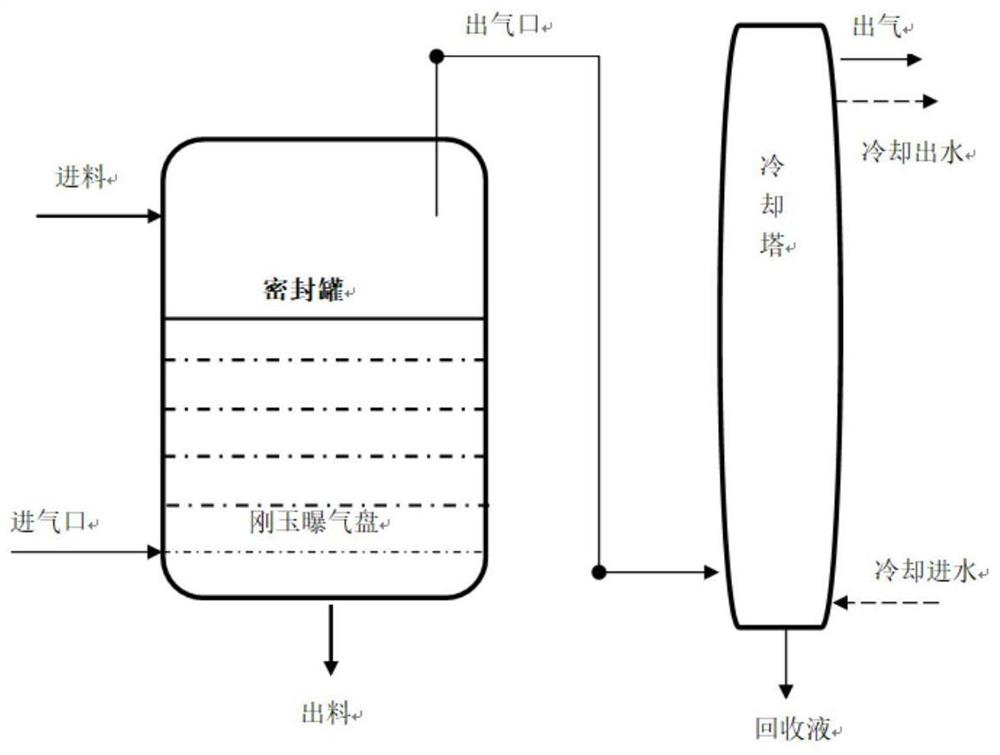

[0040] Embodiment 1 adopts the inventive method to reduce ethyl acetate in liquor

[0041] At 26°C, put 2.5L of brewed liquor into a 5L airtight tank (such as figure 1 Shown), through the air inlet of the sealed tank, with the speed of 0.8 times the liquid phase volume, that is, 2L / min, the nitrogen gas with a purity of 99.9% is continuously fed into the sealed tank for 40 minutes. After the nitrogen flows through the liquor, it is discharged from the outlet, and then flows into the cooling tower. In the cooling tower, the nitrogen is separated from the ethyl acetate. After the separation, the nitrogen is directly discharged into the air, and the liquid ethyl acetate can be reused.

Embodiment 2

[0042] Embodiment 2 adopts the inventive method to reduce ethyl acetate in liquor

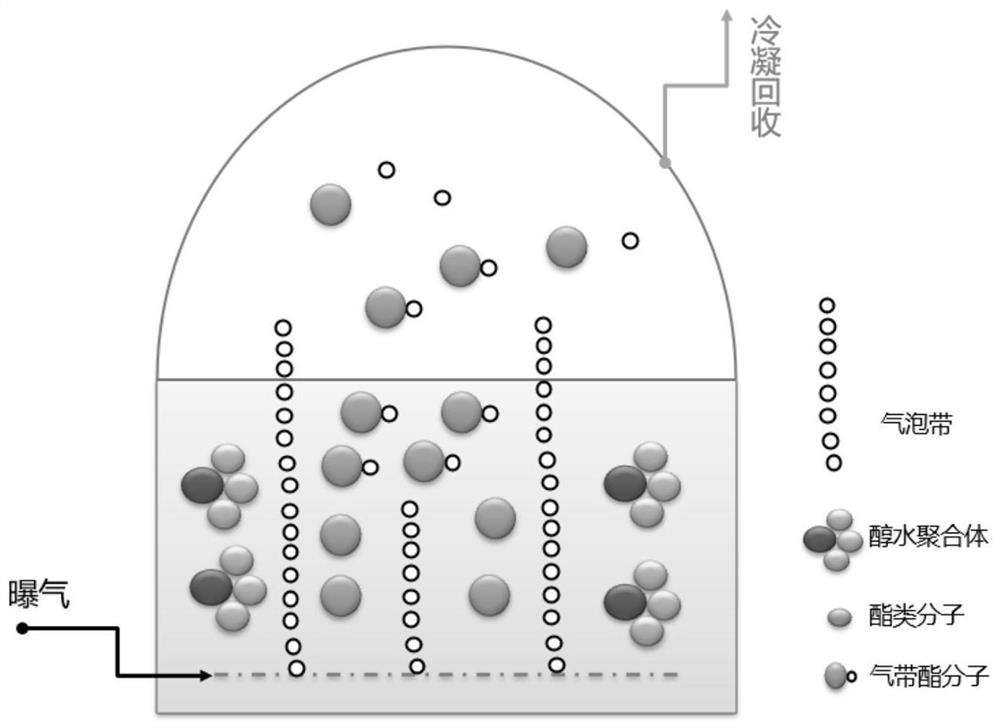

[0043] At 25°C, put 3L of brewed liquor into a 5L sealed tank, and through the air inlet of the sealed tank, an aeration plate is arranged at the bottom of the sealed tank; min speed, continuously feed nitrogen into the sealed tank, nitrogen enters the liquor through the aeration pan, and disperses evenly in the liquor, as the nitrogen is continuously injected into the liquor, the ethyl acetate in the liquor out, and exits the gas outlet together with the nitrogen, and then enters the cooling tower where the nitrogen is separated from the ethyl acetate. In this embodiment, the nitrogen gas is introduced for 60 minutes.

Embodiment 3

[0044] Embodiment 3 adopts the inventive method to reduce ethyl acetate in liquor

[0045] At 35°C, put 2.5L of brewed liquor into a 5L airtight tank, through the air inlet of the airtight tank, with 0.8 times the liquid phase volume, that is, at a speed of 2L / min, to the airtight tank continuously Into the nitrogen, through the time of 40min. After the air flows through the liquor, it is discharged from the air outlet, and then flows into the cooling tower. In the cooling tower, the nitrogen is separated from the ethyl acetate. After the separation, the nitrogen is directly discharged into the air, and the liquid ethyl acetate can be reused.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com