Manufacturing process of arc-light-proof flame-retardant army green fabric and fabric

A production process, military green technology, applied in the field of textile printing and dyeing, can solve the problems of poor arc light resistance, etc., achieve good flame retardancy, improved level of arc light discoloration resistance, and good color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

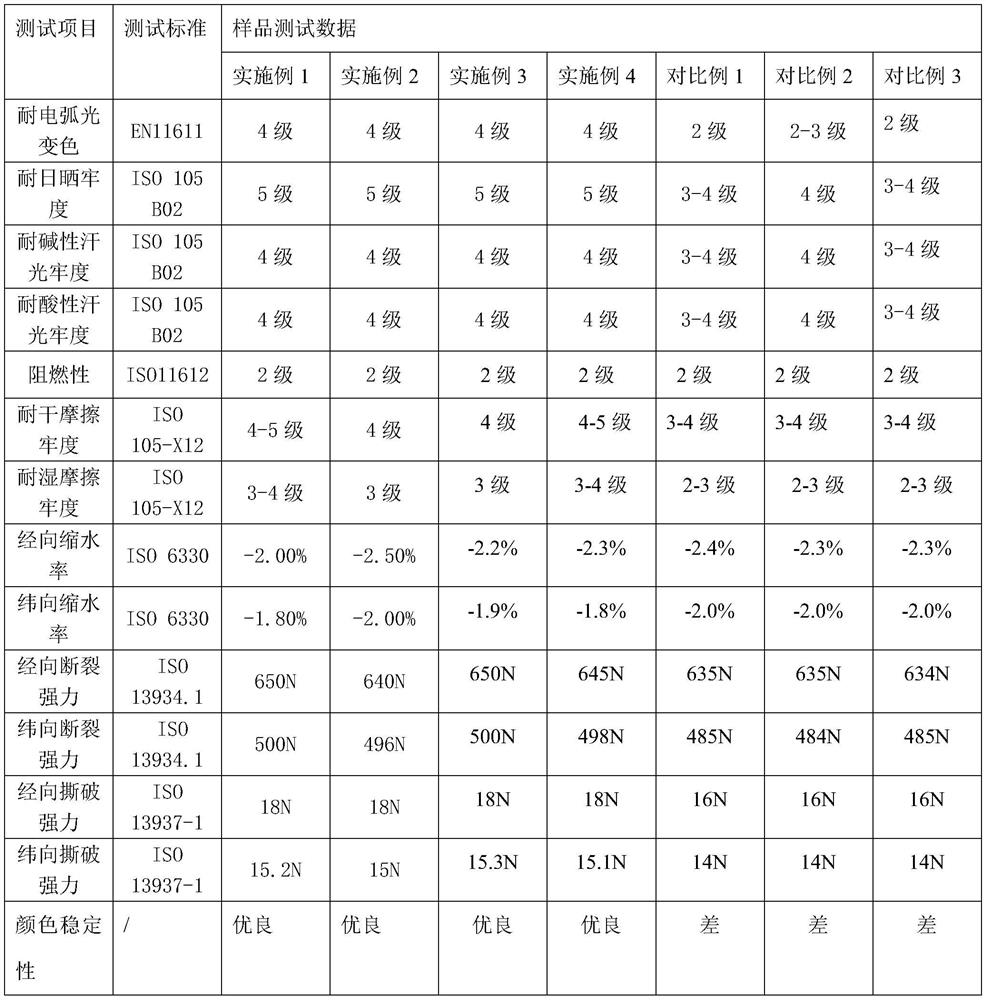

Examples

Embodiment 1

[0035] A kind of anti-arc light flame retardant military green fabric manufacturing process, comprising the following steps:

[0036] 1), scouring and bleaching: adopt the method of two dips and two rollings to soak and roll the scouring and bleaching working liquid, the crawler temperature is 98°C, the stacking time is 80 minutes, the vehicle speed is 55 m / min, and the liquid carrying rate is 95%; the formula of the scouring and bleaching working liquid is : Sodium sulfite 3g / l, refining agent MJ206 8g / l, chelating dispersant HS 2g / l, water glass 8g / l, sodium hydroxide 60g / l, hydrogen peroxide 2g / l;

[0037] 2), singeing: the speed of the vehicle is 80 m / min, the singeing method is performed under two burners, one positive and one reverse, and the effect is required to reach 4-5 grades, and the surface fluff of the shaped fabric is removed to obtain the singed fabric;

[0038] 3), mercerizing: the singeing fabric is padded with lye at a speed of 65 m / min and an alkali concent...

Embodiment 2

[0047] This embodiment is based on embodiment 1, and the difference with embodiment 1 is:

[0048] The formula of the vat dye solution is: 28 parts of vat olive T, 11 parts of vat olive green B, and 1.5 parts of vat yellow 3RT.

Embodiment 3

[0050] This embodiment is based on embodiment 1, and the difference with embodiment 1 is:

[0051] The formula of the vat dyeing solution is: 30 parts of reduced olive T, 12 parts of reduced olive green B, 2.0 parts of reduced vat yellow 3RT;

[0052] The reducing solution in the reduction steam color development is composed of the following components:

[0053] 45 parts of caustic soda, 45 parts of hydrosulfite.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap