Plastic laser transmittance detection equipment

A technology of laser transmission and laser transmitter, applied in transmittance measurement and other directions, to achieve the effect of improving portability and stability, accurate and stable laser transmittance, and reducing defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

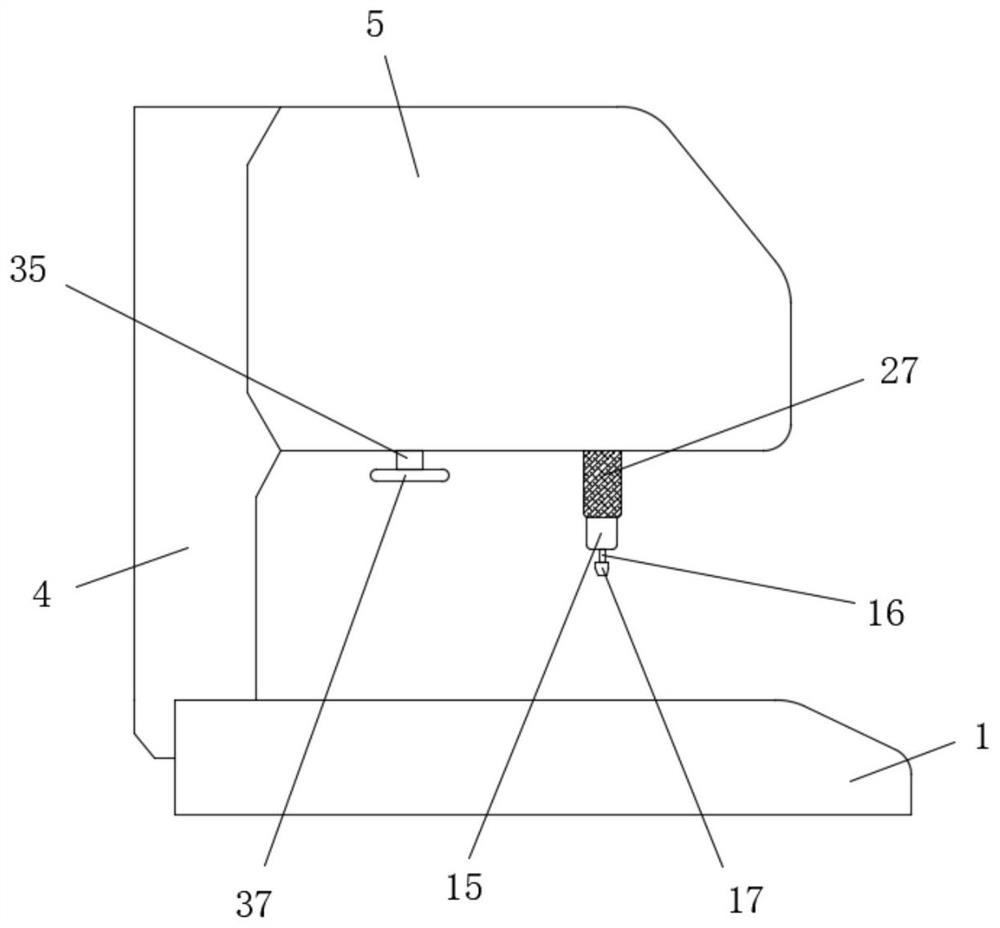

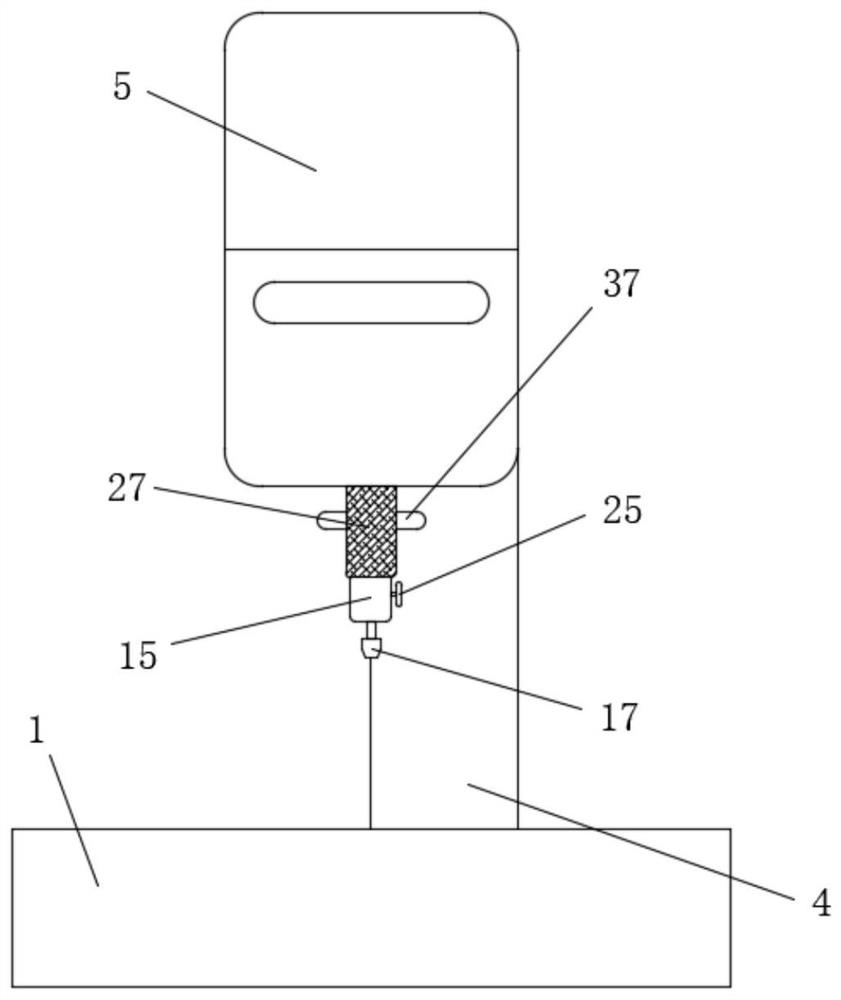

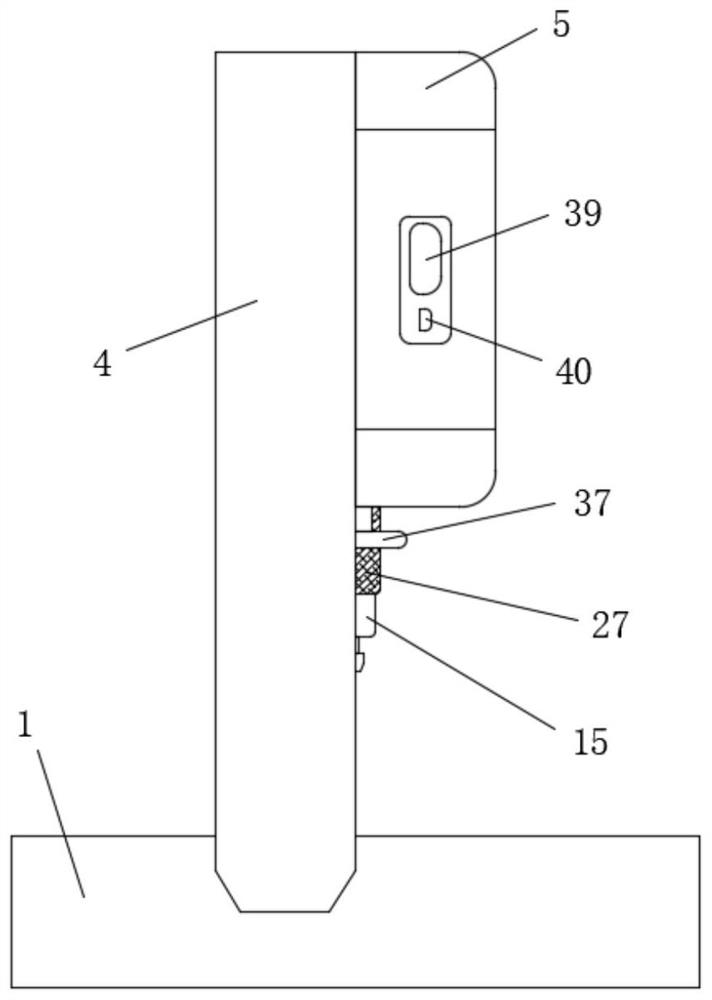

[0043] refer to Figure 1-11 , a plastic laser transmittance detection equipment, including a hardware system 100 and a software system 200, and a test platform 1 and a support column 4 for installing the hardware system 100, and the support column 4 is fixedly connected to the top side of the test platform 1, The top of the measuring platform 1 is provided with a sample placement slot 2, and the hardware system 100 includes a CPU module 1001, a power supply module 1002, a laser output module 1003, a power detection module 1004, a handheld module 1005, a data output module 1006, and a man-machine interface 1007, software The system 200 includes a real-time operating system 2001, a calibration system 2002, a data acquisition program 2003, a signal display program 2004, a data reading and writing program 2005, and a communication system 2006. The CPU module 1001 uses an imported semiconductor single-chip microcomputer, and the power supply module 1002 is the entire circuit Provi...

Embodiment 2

[0045] Further improvement on the basis of the first embodiment: the bottoms of the four support plates 9 are provided with chute 10, and the four chute 10 are slidingly connected with sliders 11, and the bottoms of the four sliders 11 respectively extend to the corresponding The bottom of the support plate 9 is connected with connecting rods 12 in rotation, and the ends of the four connecting rods 12 extending close to each other are respectively connected to the top of the movable plate 13 in equidistant rotation, through the cooperation of the slider 11 and the connecting rods 12, it is easy to move. Any movement of the plate 13 in the horizontal position, two rollers 38 are symmetrically rotated on both sides of the four sliders 11, and a plurality of rollers 38 are respectively connected to the inner wall of the chute 10 by rolling, and the rollers 38 are used to facilitate the movement of the sliders 11. The sliding of the movable plate 13 improves the flexibility of move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com