Intelligent inspection and quality inspection robot for biomass material warehouse

A technology of intelligent inspection and material storage, applied to thermometers, instruments, manipulators, etc. that use electric/magnetic elements that are directly sensitive to heat, can solve the problem that smoke detectors and combustible gas detectors cannot ensure full coverage and increase biomass Solve problems such as labor costs of direct-fired power plants, inability to monitor safety of material warehouses, etc., to achieve the effects of saving labor costs, ensuring timeliness, and ensuring fuel supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

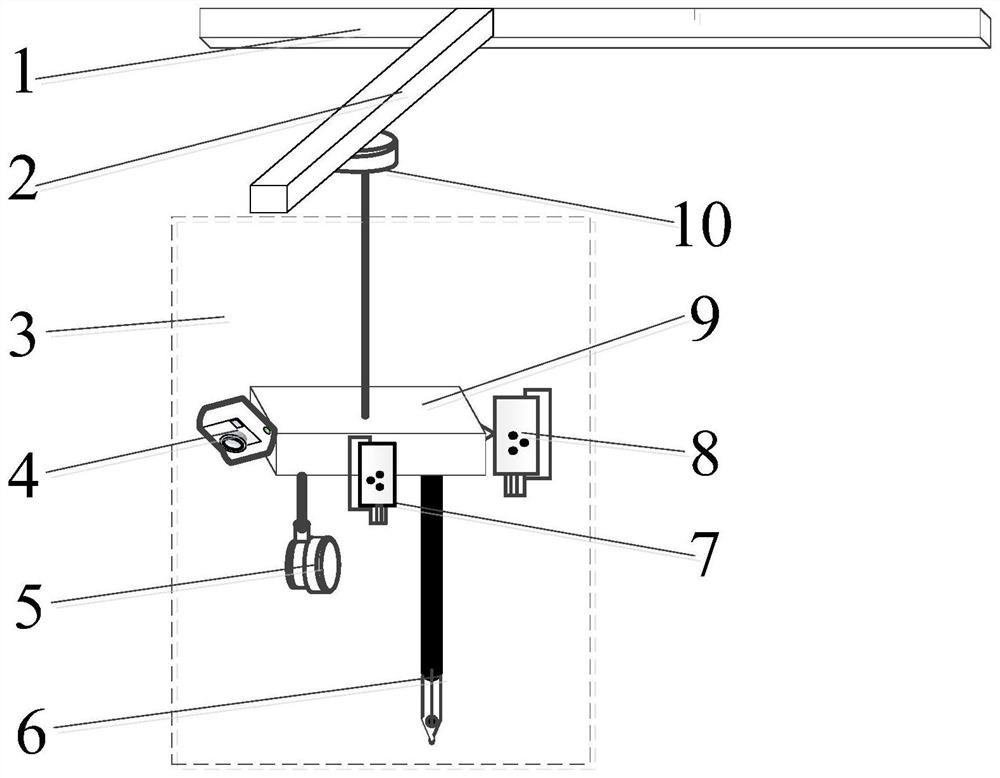

[0032] Such as figure 1As shown, an intelligent inspection and quality inspection robot for a biomass material warehouse includes: a biomass warehouse driving vehicle 1, a sliding guide rail platform 2, an intelligent inspection and quality inspection robot 3 and a mobile hanging rail 10; a sliding guide rail platform 2 The two ends of the two sides are respectively connected to the guide grooves on both sides of the vehicle 1 of the biomass material warehouse, and the sliding guide rail platform 2 is slidably connected to the mobile suspension rail 10; the intelligent inspection and quality inspection robot 3 is provided with a control platform 9, and the four sides of the control platform 9 It is equipped with 3D camera 4 (structured light camera, binocular camera or TOF camera), gas detector 5, temperature measuring thermocouple 6 (armored thermocouple with steel pipe: T type, E type, N type, S type, etc. Thermocouple), positioning camera 7 (two-dimensional code positioning...

Embodiment 2

[0034] Taking agricultural and forestry waste direct-fired power plants as an example, it is first necessary to understand the number of warehouses, warehouse sizes, driving configuration, smoke detector configuration, safety risk points, manual quality inspection mode, and manual fuel stacking inspection of the agricultural and forestry waste material yard. Temperature cycle, fuel type, daily inventory management mode and other information.

[0035] Taking an agricultural and forestry waste direct-fired power plant with an installed capacity of 30MW as an example, there are four dry biomass storages, two of which are equipped with cranes (116 meters long, 66 meters wide, and 12 meters high) ); the warehouse of the power station is equipped with a fire alarm system including smoke detectors, and the stacking temperature of the warehouse is checked twice a day in the morning and in the afternoon; It is carried out manually, and the work content includes fuel type identification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com