Preparation method of fermented chrysanthemum cold dressing sauce with alpha-glucosidase inhibitory activity

A technology of glucosidase and inhibitory activity, which is applied in the field of preparation of fermented chrysanthemum cold sauce, can solve the problems of restricting the health effect of food and low bioavailability of active ingredients, and achieve the improvement of α-glucosidase inhibitory activity and high-quality taste and flavor , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Take dried chrysanthemum as a raw material, wash the skin of chrysanthemum, and then carry out over-flow immersion sterilization in ozone water for 5-15 minutes, and divide the chrysanthemum into several chrysanthemum petals after draining.

[0043] 2. Take dried Cornus officinalis as raw material, wash the epidermis of Cornus officinalis, then immerse and sterilize it in ozone water for 5-15 minutes, and obtain Cornus officinalis after draining.

[0044] 3. Take dried longan meat as a raw material, wash the skin of the longan meat, and then carry out flow-type immersion sterilization in ozone water for 5-15 minutes. After draining, divide the longan meat into several small pieces to obtain longan meat pieces.

[0045] 4. Mix water, chrysanthemum, dogwood and longan meat together at a mass ratio of 20:5:3:2, then add 0.2g each of bifidobacteria, 0.2g of fruit and vegetable fermentation bacteria and 4g of sucrose each, at 30°C, in a shaker Anaerobic fermentation was car...

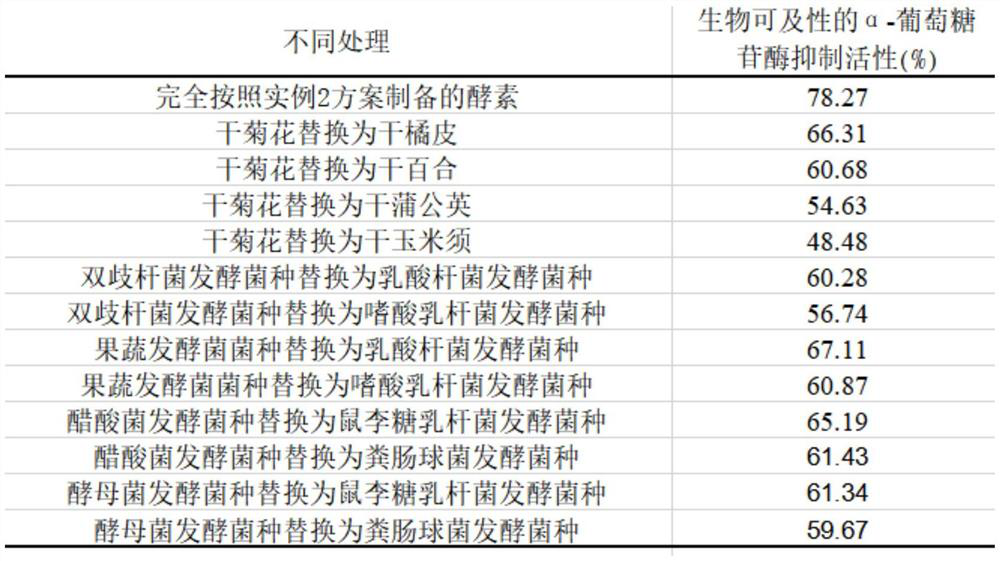

Embodiment 2

[0054] 1. Take dried chrysanthemum as raw material, wash the chrysanthemum epidermis, and then carry out over-flow immersion sterilization in ozone water for 5-15 minutes, and divide the chrysanthemum into several chrysanthemum petals after draining.

[0055] 2. Take dried Cornus officinalis as raw material, wash the epidermis of Cornus officinalis, then immerse and sterilize it in ozone water for 5-15 minutes, and obtain Cornus officinalis after draining.

[0056] 3. Take dried longan meat as a raw material, wash the skin of the longan meat, and then carry out over-flow immersion sterilization in ozone water for 5-15 minutes. After draining, divide the longan meat into several small pieces to obtain longan meat pieces.

[0057] 4. Mix water, chrysanthemum, cornus officinalis and longan meat at a mass ratio of 20:7:3.5:2.5, then add 0.2g of bifidobacterium, 0.2g of fruit and vegetable fermentation bacteria and 4g of sucrose, at 30°C, in a shaker Anaerobic fermentation was carr...

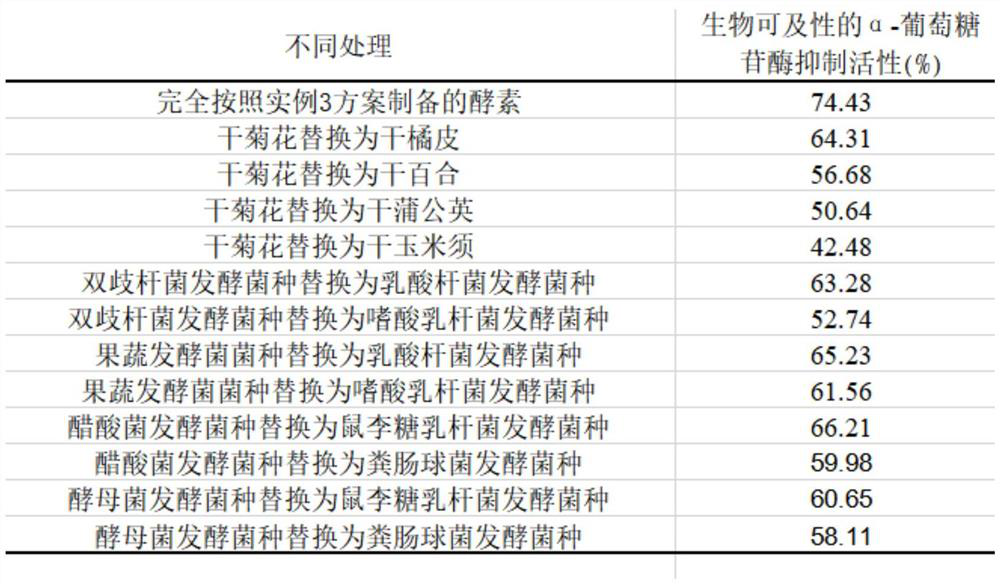

Embodiment 3

[0066] 1. Take dried chrysanthemum as raw material, wash the chrysanthemum epidermis, and then carry out over-flow immersion sterilization in ozone water for 5-15 minutes, and divide the chrysanthemum into several chrysanthemum petals after draining.

[0067] 2. Take dried Cornus officinalis as raw material, wash the epidermis of Cornus officinalis, then immerse and sterilize it in ozone water for 5-15 minutes, and obtain Cornus officinalis after draining.

[0068] 3. Take dried longan meat as a raw material, wash the skin of the longan meat, and then carry out over-flow immersion sterilization in ozone water for 5-15 minutes. After draining, divide the longan meat into several small pieces to obtain longan meat pieces.

[0069] 4. Mix water, chrysanthemum, dogwood and longan meat together in a mass ratio of 22:9:4:3, then add 0.2g of bifidobacteria, 0.2g of fruit and vegetable fermentation bacteria and 4g of sucrose, in a shaker at 28°C Perform anaerobic fermentation for 5 da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com