Vernicia fordii seed husking equipment

A technology of tung seed and equipment, which is applied in the field of tung seed shelling equipment, can solve the problems of undesigned extrusion mechanism, unfavorable subsequent use, unfavorable shelling, etc., and achieve the effect of improving shelling efficiency and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

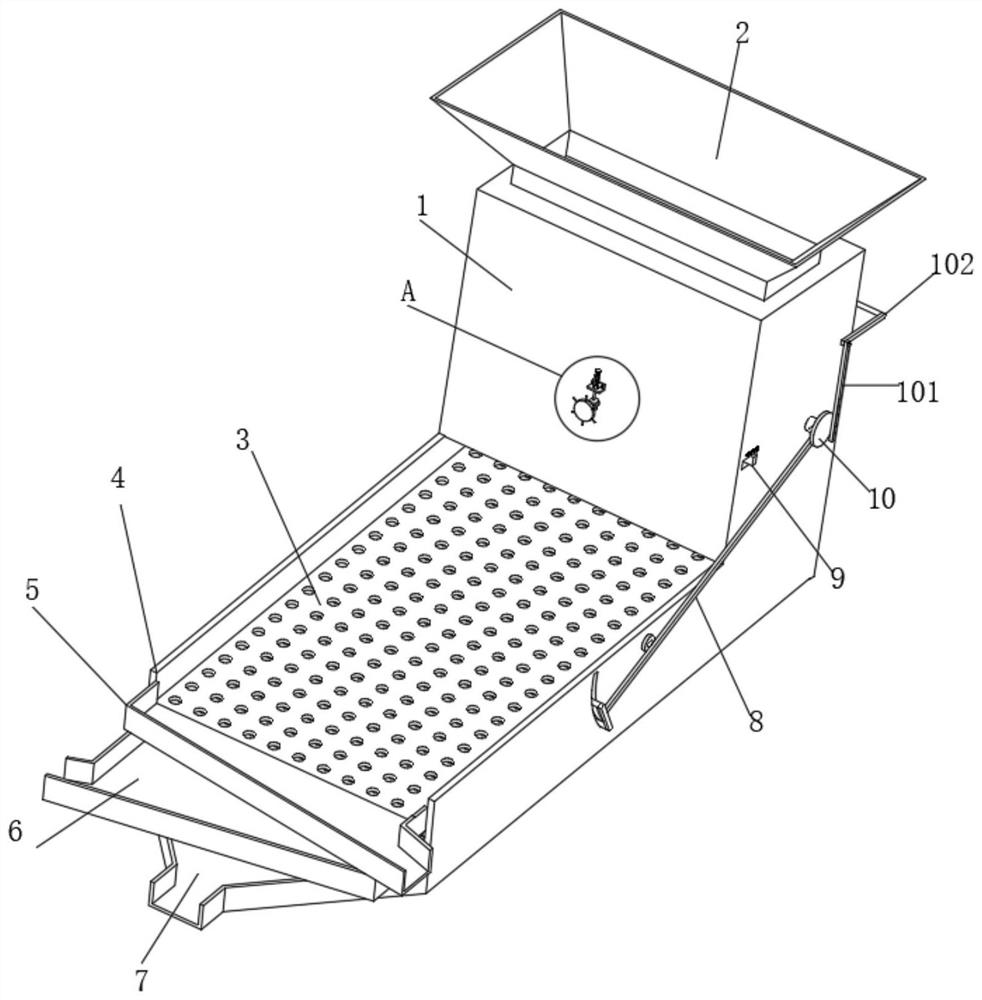

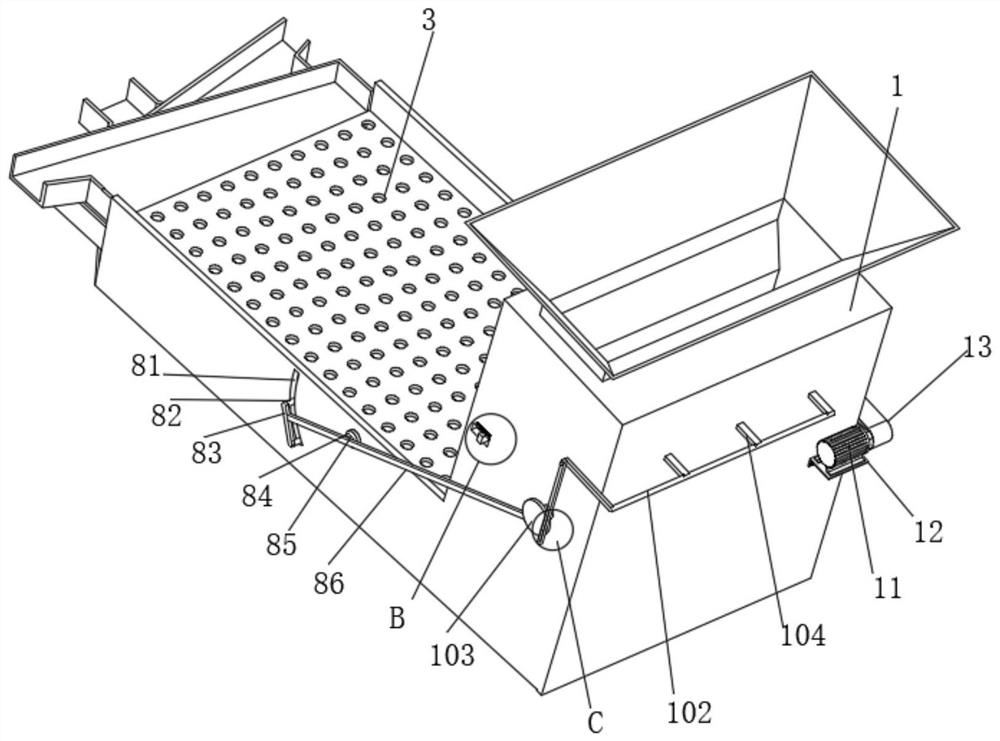

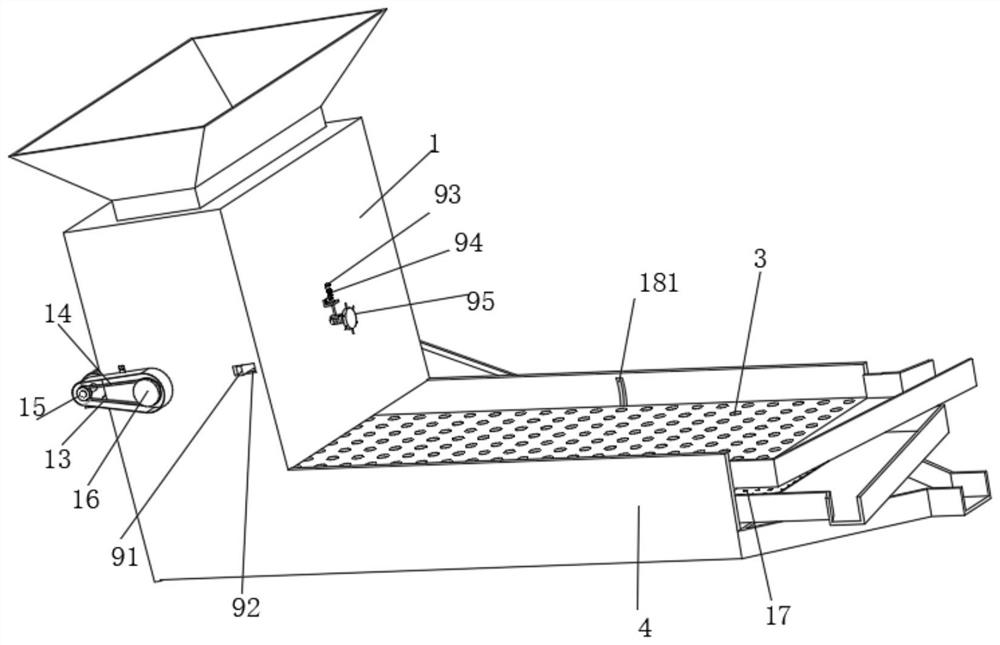

[0040] like figure 1 , 2, 3, 4, 5, 6, 9, and 10 show a kind of shelling equipment for tung oil seeds, comprising a shell breaking box 1, and the straight hole of the shell breaking box 1 is fixedly connected with a feed pipe 2, and the shell breaking box 1 is in the The lower part of the feed pipe 2 is provided with a broken shell structure, and the broken shell structure includes a driving motor 11, a belt 14, a driving pulley 15, a driven pulley 16, a shell breaking roller 18 and a fixed roller 19, and the shell breaking box 1 is fixedly connected with an installation Plate 12, driving motor 11 is fixedly installed on the mounting plate 12, and the output end of driving motor 11 is fixedly connected with driving pulley 15, and driving pulley 15 is movably connected with belt 14, and belt 14 is movably connected with driven pulley 16, shell breaking roller 18 The left and right ends of the shell are fixedly connected with connecting shaft 181, and the shell breaking box 1 is...

Embodiment 2

[0043] Embodiment 2 is a further improvement to Embodiment 1.

[0044] like figure 1 , 2 A kind of tung seed peeling equipment shown in , 3, 6, comprises cracking case 1, and feed pipe 2 is fixedly connected in the straight hole of breaking case 1, and breaking case 1 is at the place below feed pipe 2 A shell breaking structure is provided, and the shell breaking structure includes a drive motor 11, a belt 14, a driving pulley 15, a driven pulley 16, a shell breaking roller 18 and a fixed roller 19, and the shell breaking box 1 is fixedly connected with a mounting plate 12, and the driving motor 11 is fixed Be installed on the mounting plate 12, the output end of drive motor 11 is fixedly connected with driving pulley 15, and driving pulley 15 is movably connected with belt 14, and belt 14 is movably connected with driven pulley 16, and the left and right ends of shell breaking roller 18 are fixedly connected with Connecting shaft 181, breaking case 1 is fixedly connected wi...

Embodiment 3

[0046] Embodiment 3 is a further improvement to Embodiment 2.

[0047] like figure 1 , 2A kind of oil tung seed shelling equipment shown in , 6, comprises broken shell case 1, is fixedly connected with feed pipe 2 in the straight hole of broken shell case 1, and broken shell case 1 is provided with at the place below feed pipe 2 Shell-breaking structure, the shell-breaking structure includes drive motor 11, belt 14, driving pulley 15, driven pulley 16, shell-breaking roller 18 and fixed roller 19, shell-breaking box 1 is fixedly connected with mounting plate 12, and driving motor 11 is fixedly installed on On the mounting plate 12, the output end of the driving motor 11 is fixedly connected with a driving pulley 15, the driving pulley 15 is movably connected with a belt 14, the belt 14 is movably connected with a driven pulley 16, and the left and right ends of the shell breaking roller 18 are fixedly connected with a connecting shaft 181, the shell breaking box 1 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com