A kind of bifunctional catalyst for oxygen evolution and oxygen reduction and preparation method thereof

A dual-function catalyst and oxygen precipitation technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of large reserves, low cost of binary nickel-cobalt-based catalysts, and binary nickel-cobalt The problem of poor catalyst conductivity and long-term stability, to achieve the effect of good methanol tolerance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

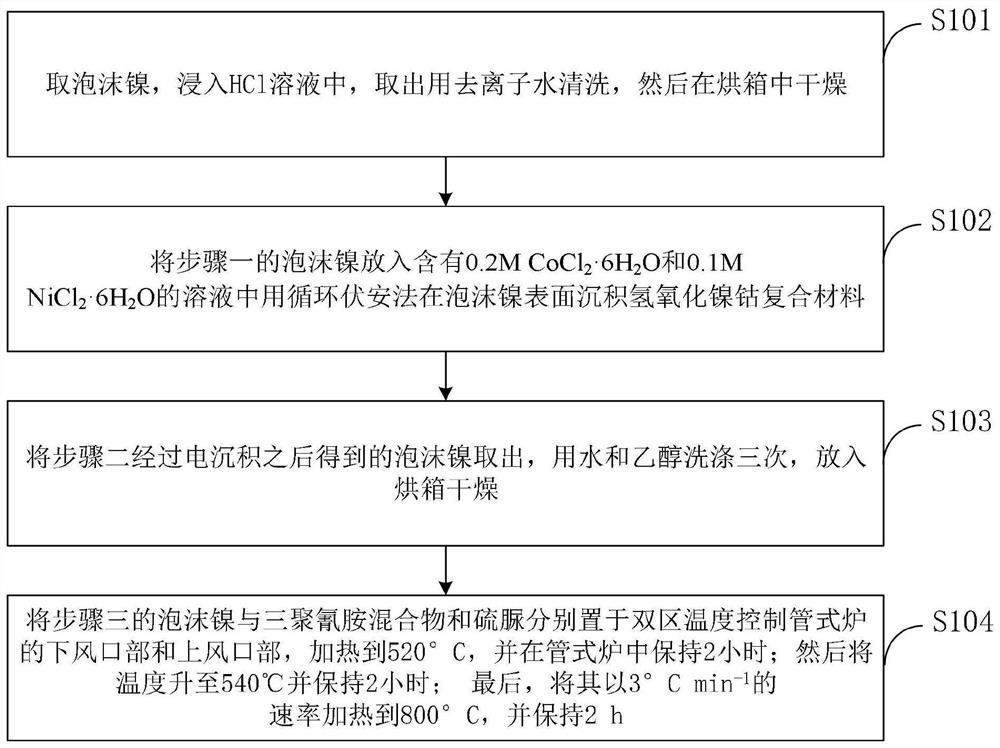

[0033] like figure 1 As shown, the preparation method of the bifunctional catalyst for oxygen evolution and oxygen reduction provided by the embodiment of the present invention includes:

[0034] S101, take foamed nickel, immerse it in HCl solution, take it out, wash it with deionized water, and then dry it in an oven;

[0035] S102, put the nickel foam of step 1 into a layer containing 0.2M CoCl 2 ·6H 2 O and 0.1M NiCl 2 ·6H 2 The nickel-cobalt hydroxide composite was deposited on the surface of nickel foam by cyclic voltammetry in a solution of O;

[0036] S103, taking out the nickel foam obtained after electrodeposition in step 2, washing with water and ethanol three times, and putting it into an oven to dry;

[0037] S104, the nickel foam of step 3 and melamine mixture and thiourea are respectively placed in the lower tuyere part and the upper tuyere part of the double-zone temperature control tube furnace, heated to 520 ° C, and kept in the tube furnace for 2 hours; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com