hollow ceo 2 Sphere@co-n/c nanocomposite material and its preparation method and application

A nanocomposite material and hollow technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, fuel cells, etc., can solve the problem of high price, stability and methanol tolerance of cathode catalyst platinum-based catalysts Poor performance, hindering commercial application and other problems, to achieve excellent oxygen reduction catalytic performance, good methanol tolerance, and improve the effect of oxygen reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

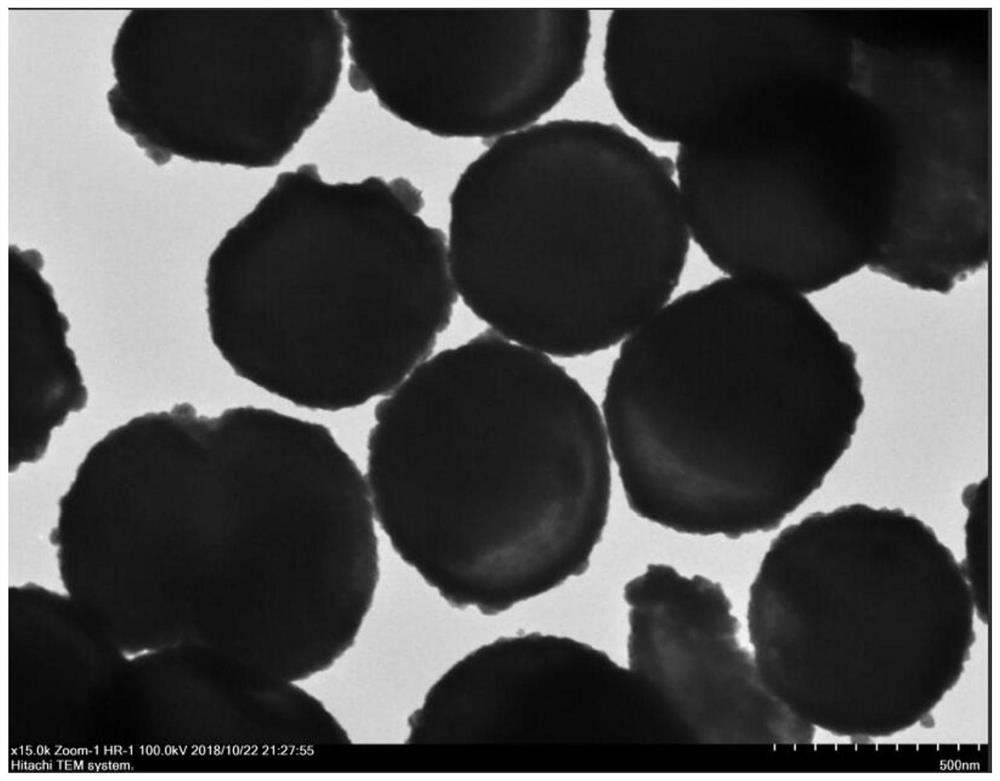

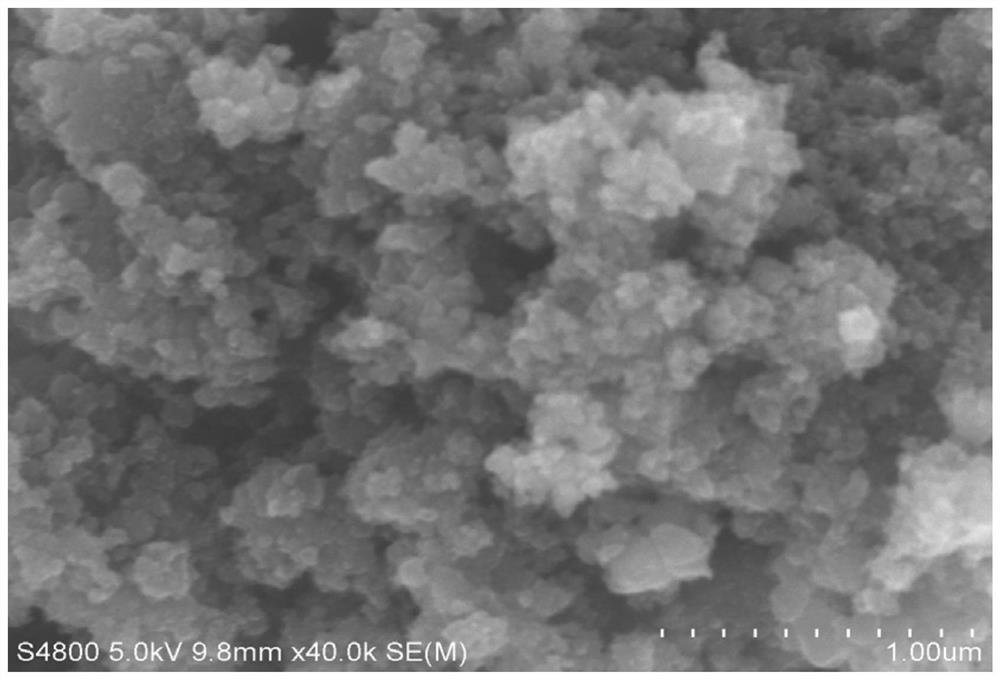

[0022] The invention provides a hollow CeO 2 The preparation method of the ball@Co-N / C nanocomposite material comprises the following steps: (1) contacting and reacting the heated cerium salt dispersed in the first solvent with polydopamine nanospheres, washing and drying the obtained product, After air gradient calcination, the hollow CeO 2 (2) In the second solvent, the hollow CeO 2 Contact reaction of spheres, cobalt source, and D-(+)glucosamine hydrochloride to prepare hollow CeO 2 spheres@Co-N / C precursor; (3) the hollow CeO 2 The sphere@Co-N / C precursor was calcined under nitrogen atmosphere to obtain the hollow CeO 2 Sphere@Co-N / C nanocomposite.

[0023] Through the above technical scheme, in the present invention, the hollow CeO 2 Contact reaction of spheres, cobalt source, and D-(+)glucosamine hydrochloride to prepare hollow CeO 2 spherical@Co-N / C precursor; the hollow CeO 2 The sphere@Co-N / C precursor was calcined under nitrogen atmosphere to obtain the hollow...

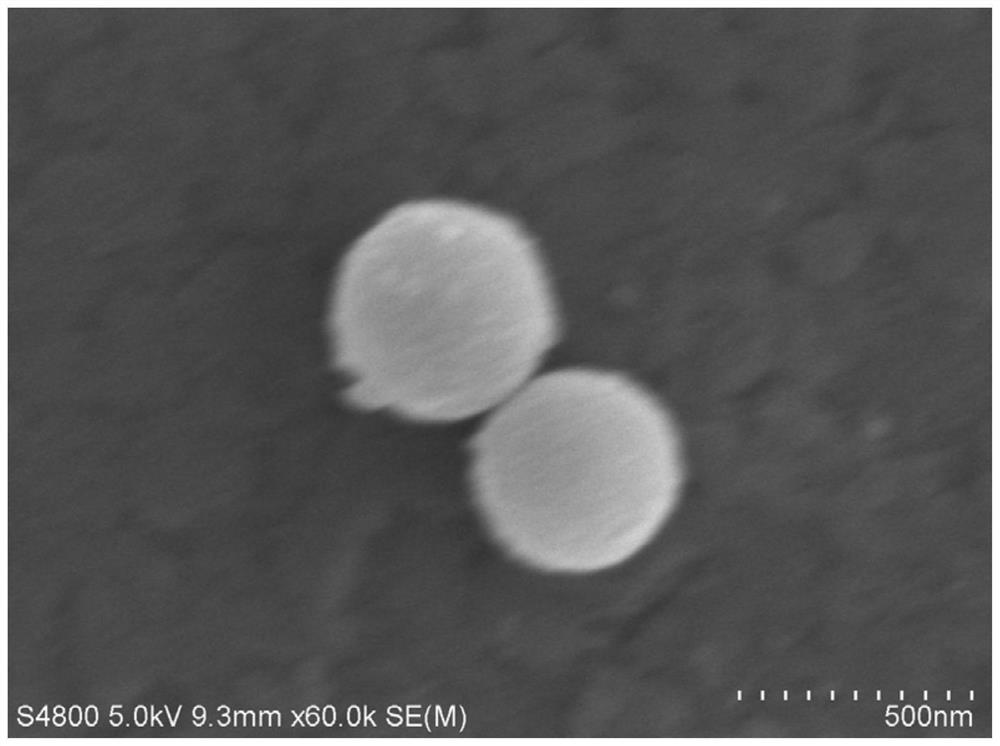

preparation example 1

[0042] CeO 2 Preparation of nanospheres: add 0.5mmol cerium nitrate hexahydrate to 20ml of ethanol, stir at 70°C for 1h for heat treatment, add 0.05g of polydopamine nanosphere solution (containing 5mL of deionized water) after ultrasonic dispersion dropwise and move to room temperature for reaction 16h, washed 3 times, and dried overnight. Then carry out gradient calcination: calcine in air at 550°C for 3h, cool down to 400°C at 1°C / min, and maintain it for 1h, and finally get a white powder that is CeO 2 small ball. Denote it as D1.

preparation example 2

[0044] Prepare CeO according to the method of Preparation Example 1 2 , denoted as C1; the difference is that the cerium nitrate hexahydrate was replaced by an equimolar amount of cerium chloride, and the amount of the polydopamine nanosphere solution was 0.1 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com