Soft and antistatic fabric care composition for removing unpleasant odor of fabric dried in shade

A fabric care and composition technology, applied in fiber treatment, textiles and papermaking, biochemical fiber treatment, etc., can solve the problem of no soft antistatic care technology that can effectively remove shade drying odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

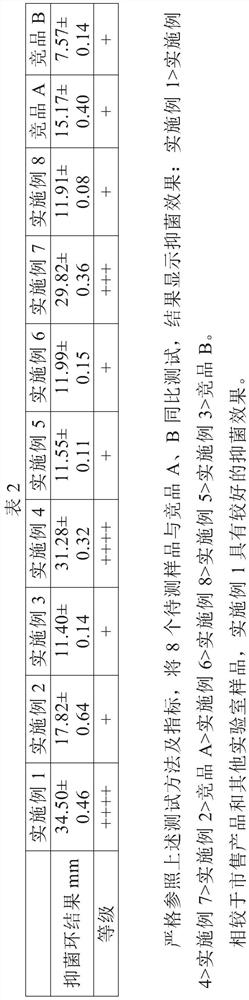

Examples

specific Embodiment approach

[0067] Below, the technical solution of the present invention will be described in detail through preferred embodiments, but the scope of the present invention is not limited to these embodiments, which are intended to illustrate the technical solution of the present invention rather than limit the scope of the present invention. The test methods for which specific conditions are not indicated in the following examples are generally in accordance with conventional conditions, or in accordance with the conditions suggested by the manufacturer. All percentages and parts are by weight unless otherwise indicated.

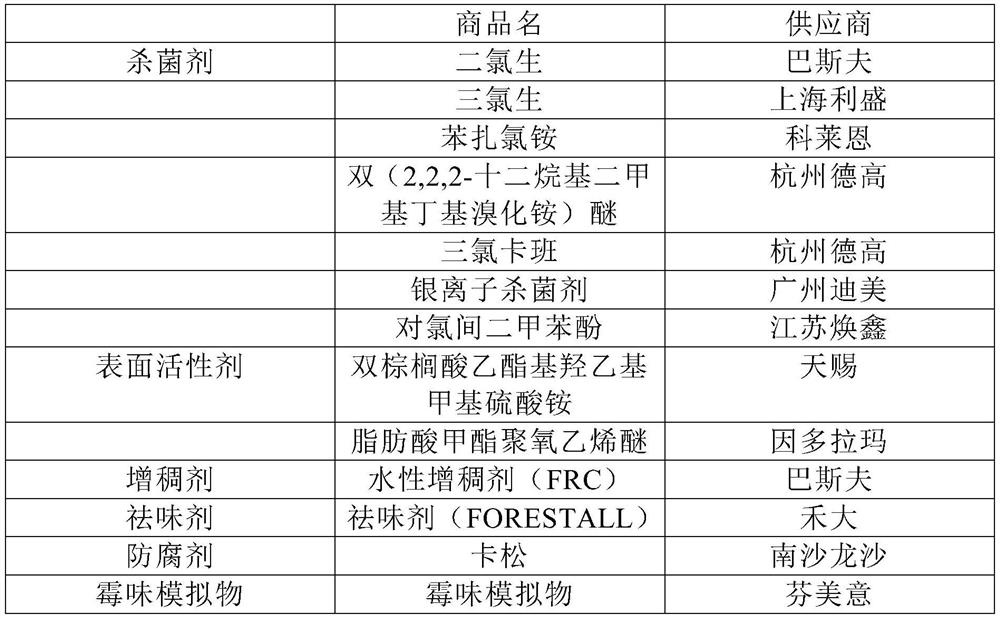

[0068] The composition and source of each raw material adopted in the following examples are as follows:

[0069]

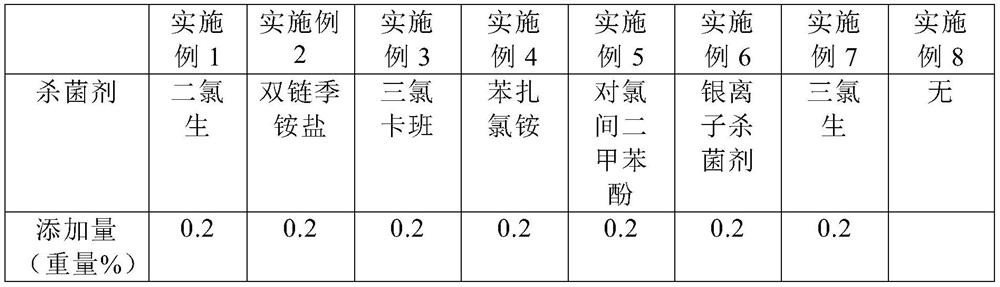

Embodiment 1

[0070] Example 1: Preparation of Fabric Care Composition

[0071] Weigh 92 parts by mass of deionized water in a beaker, heat it to 50°C, and add 0.7 parts by mass of water-based thickener (FRC) and 5.6 parts by mass of ethyl palmitate ethyl hydroxyethyl in turn at a speed of 700 rpm. Ammonium methyl sulfate, 0.56 parts by mass of fatty acid methyl ester polyoxyethylene ether, 0.1 part by mass of Cathone, and 0.2 parts by mass of diclosan, added deionized water to make up 100 parts by mass, stirred evenly, and set aside.

Embodiment 2

[0072] Example 2: Preparation of fabric care composition

[0073] Weigh 92 parts by mass of deionized water in a beaker, heat it to 50°C, and add 0.7 parts by mass of water-based thickener (FRC) and 5.6 parts by mass of ethyl palmitate ethyl hydroxyethyl in turn at a speed of 700 rpm. Ammonium methyl sulfate, 0.56 parts by mass of fatty acid methyl ester polyoxyethylene ether, 0.1 parts by mass of Cathone, 0.2 parts by mass of two (2,2,2-dodecyl dimethyl butyl ammonium bromide) ether, add deionized water to make up 100 parts by mass, stir evenly, and set aside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com