Ultrahigh-voltage air-core reactor

An air-core reactor, ultra-high voltage technology, applied in the direction of transformer/inductor cooling, transformer/inductor coil/winding/connection, transformer/inductor parts, etc. Single, high withstand voltage requirements, etc., achieve compact and novel structure, solve connection and installation problems, and have good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The application will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present application.

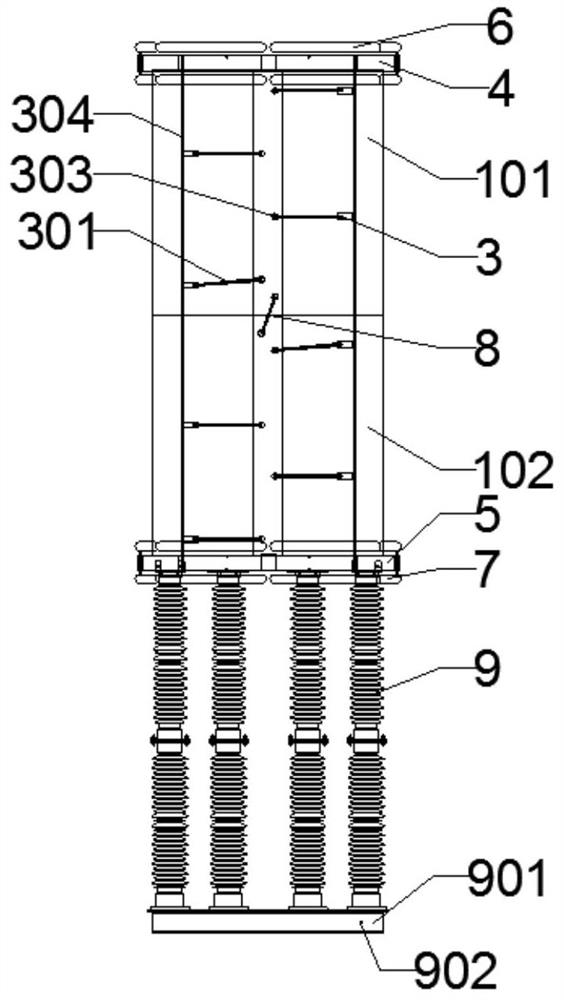

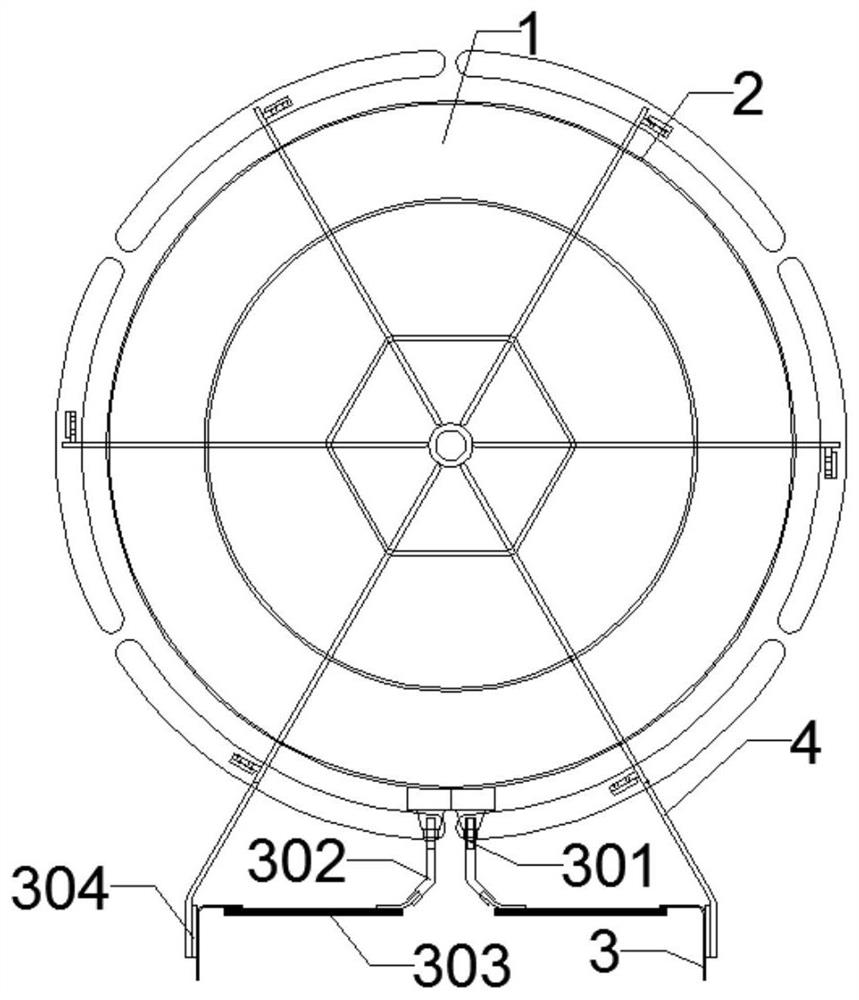

[0022] Such as figure 1 As shown, the ultra-high voltage air-core reactor of the present invention mainly includes a coil 1 , a voltage equalizing ring and a supporting insulator 9 .

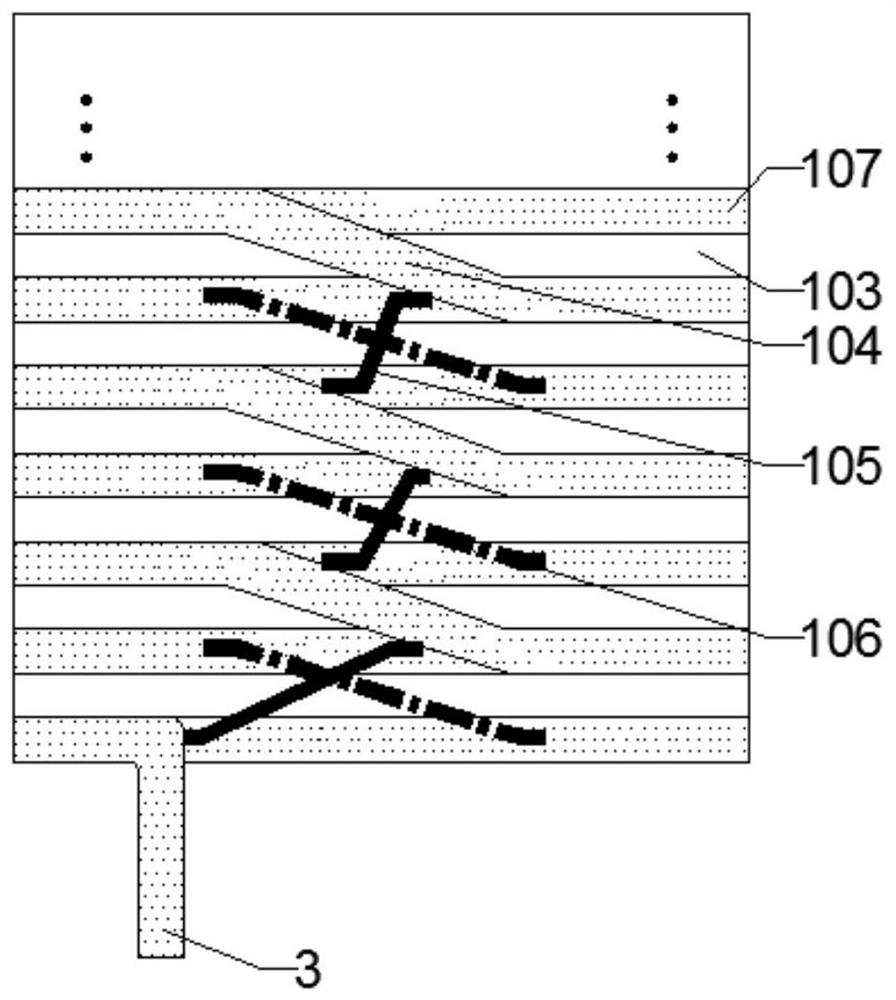

[0023] The coil 1 includes an upper coil 101, a lower coil 102, an insulating layer 2 and at least two terminals 3. The upper coil 101 and the lower coil 102 are connected in series through the connecting rod 8, that is, the nut at the bottom of the upper coil 101 and the lower coil 102 The uppermost nut needs to be connected through the connecting rod 8 to connect the upper and lower coils in series. The coil 1 is a cylindrical structure, and the outer diameter of the coil 1 is less than or equal to 1995mm.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com