Back contact type full-color LED display panel and manufacturing method thereof

A back-contact, display panel technology, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as reducing user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] In order to more clearly describe a back-contact full-color LED display panel proposed by the present invention and its manufacturing method, preferred embodiments of the present invention will be described in detail below with reference to the drawings.

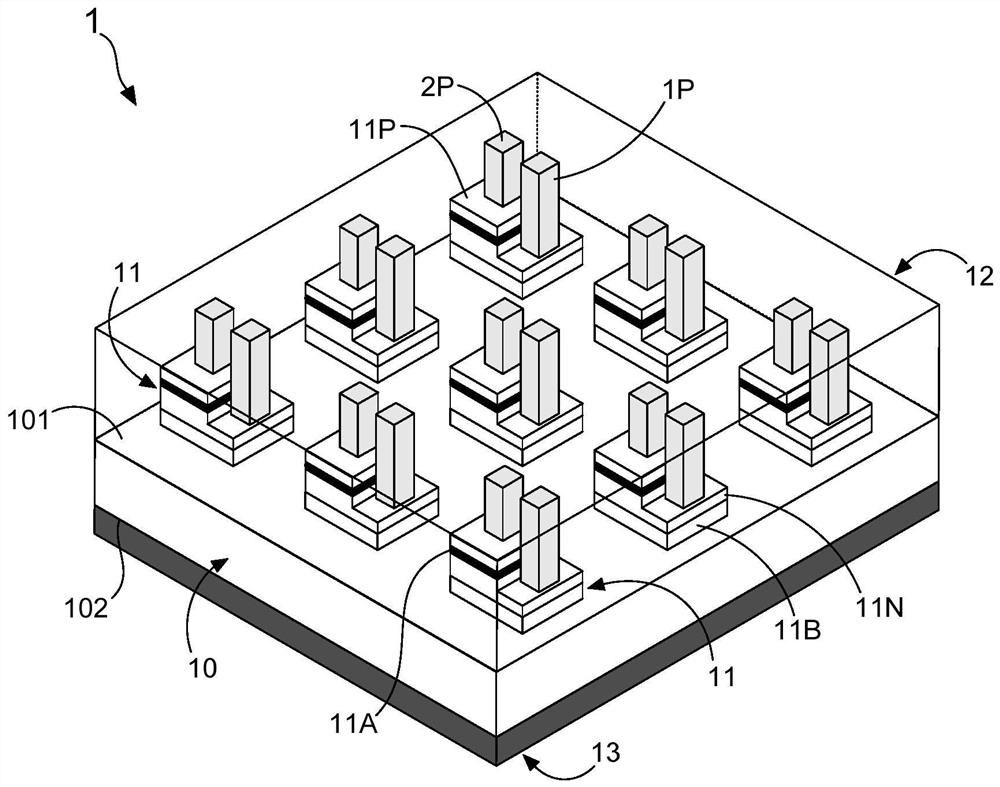

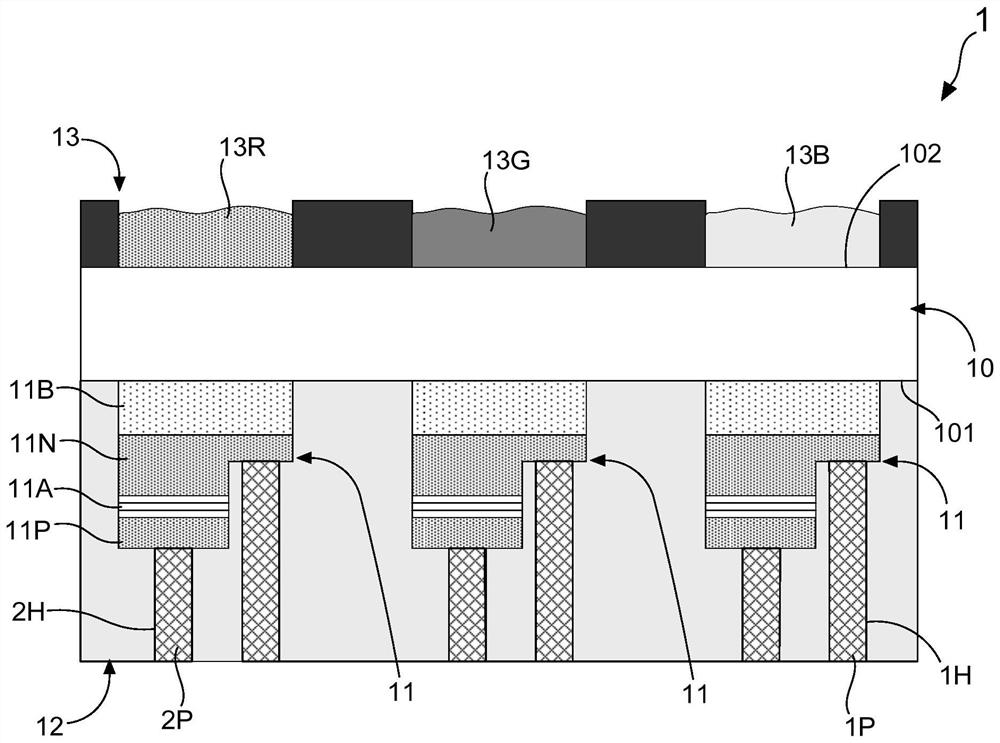

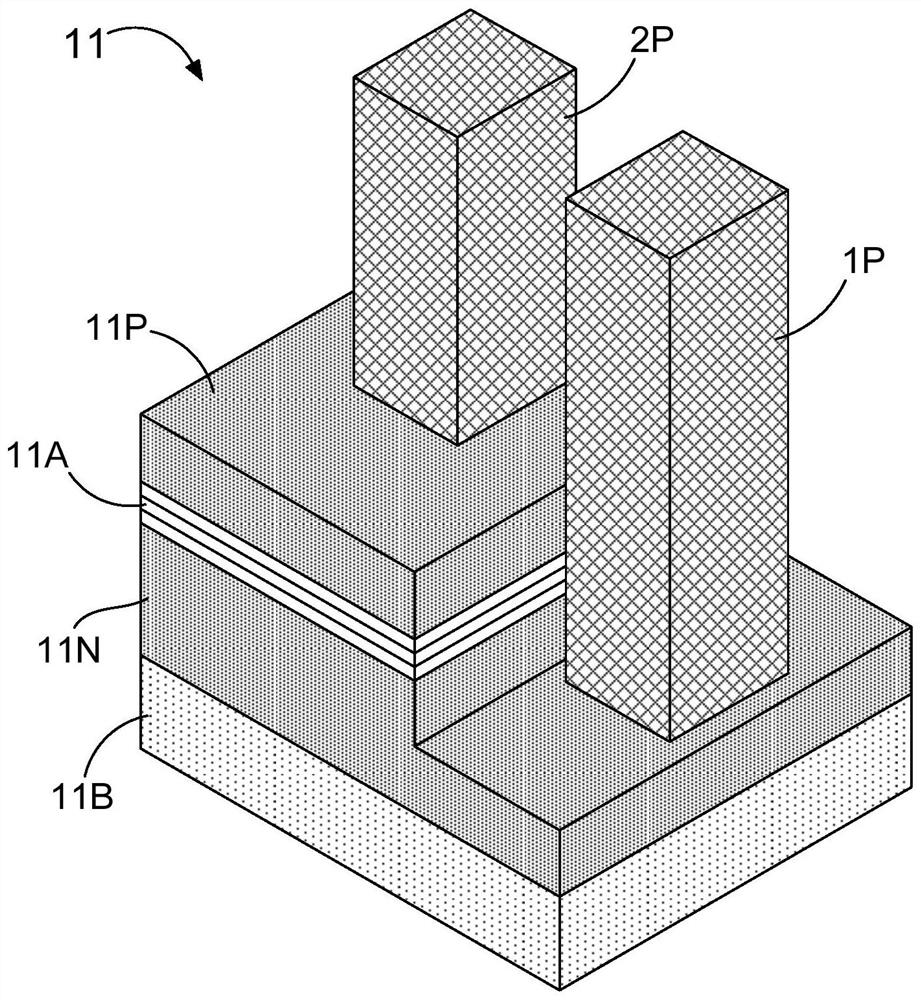

[0088] Structure of back-contact full-color LED display panel

[0089] figure 1 A schematic perspective view showing a back-contact full-color LED display panel of the present invention, and figure 2 It shows the first schematic side sectional view of the back-contact full-color LED display panel of the present invention. Such as figure 1 and figure 2 As shown, the back-contact full-color LED display panel 1 of the present invention mainly includes: a double-sided polished light-transmitting substrate 10, M×N LED light-emitting structures 11, an insulating layer 12, and a light conversion unit 13; wherein, Two surfaces of the double-sided polished light-transmitting substrate 10 are respectively used as a carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com