Methods and systems for generating high peak power laser pulses

A technology of laser pulses and generation methods, applied in lasers, laser devices, laser welding equipment, etc., can solve the problems of complex optical systems, complex and expensive injection, expensive and bulky, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

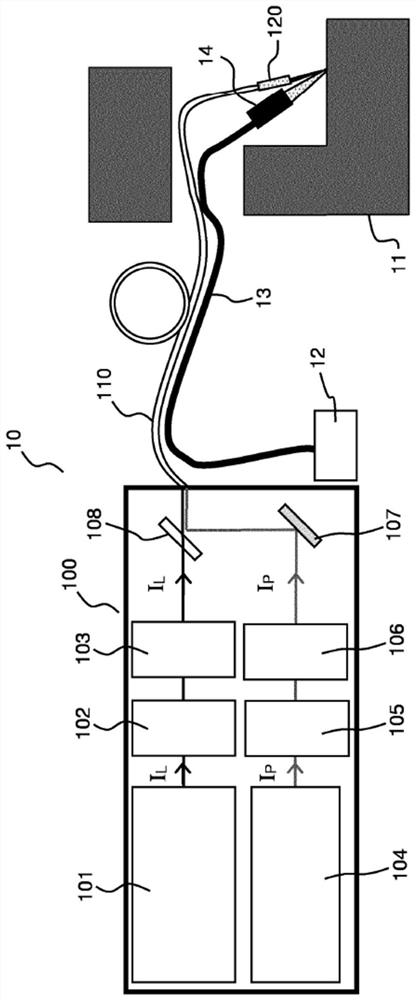

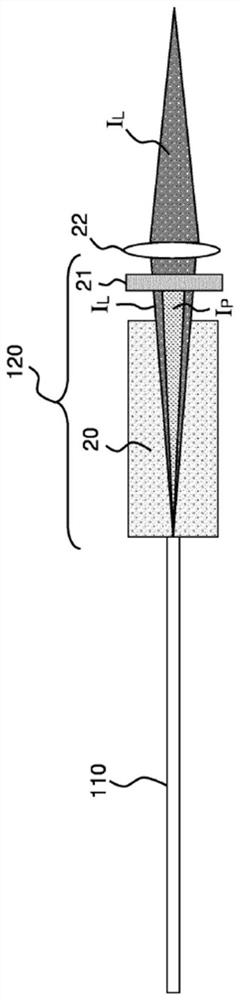

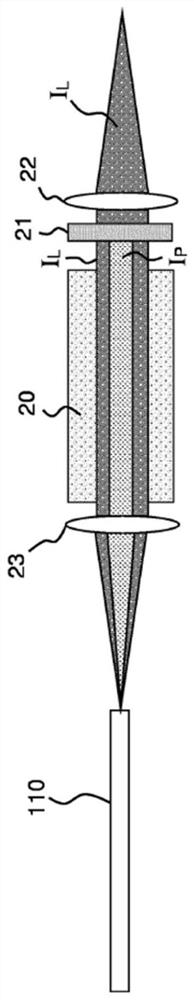

[0064] In this specification, of interest is the generation of high peak power pulses, suitable for generating laser shocks in materials.

[0065] The interaction of high illumination pulses (light power delivered per unit area) (typically on the order of millions of watts per square centimeter) with the material causes sudden heating of the illuminated surface and vaporization of this illuminated surface in the form of a plasma, a plasma And then relax. This is called laser shock. Laser shock is a mechanism in which the light / material interaction time is very short (typically tens of nanoseconds), so that, as with laser cutting or laser welding methods, there is no appreciable increase in the temperature of the part to be processed. Laser shock can be induced in one direction using a constrained layer. Specifically, in the absence of a constrained layer, the spreading of the laser shock occurs in the range of 4π steradians.

[0066] More precisely, in the case of laser sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com