Circulating refrigerating and filtering system for machine tool cutting cooling liquid

A filtration system and coolant technology, used in manufacturing tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve problems such as easy scratching of processed parts, reduced cooling effect, etc., to achieve effective cooling treatment, improve service life, Guaranteed air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

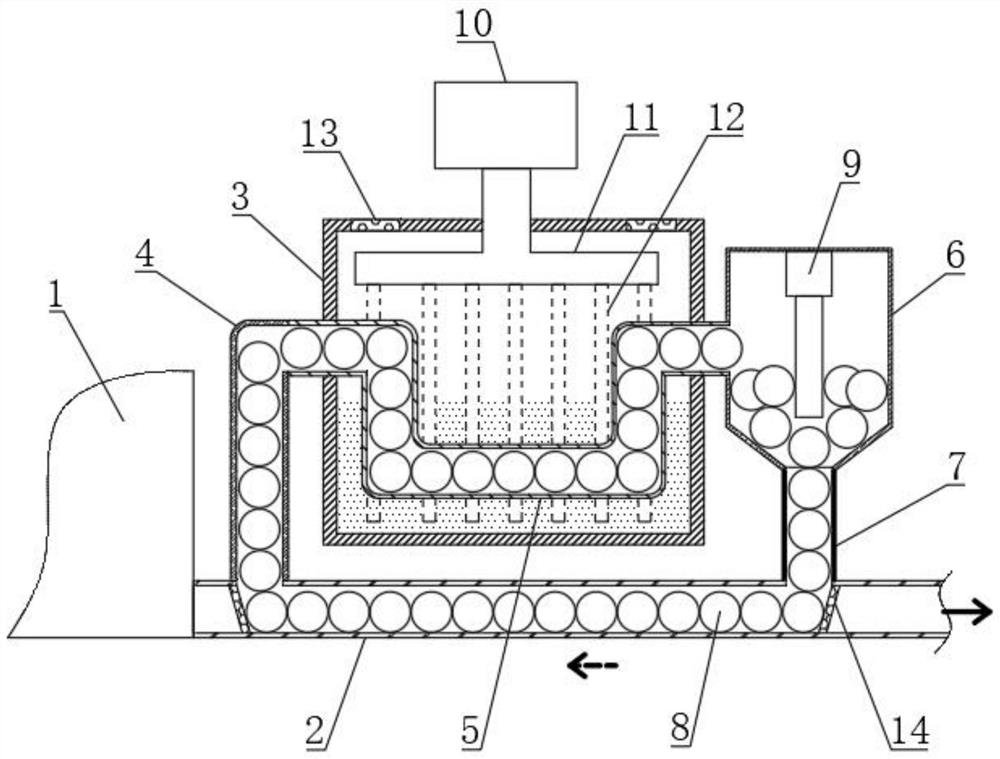

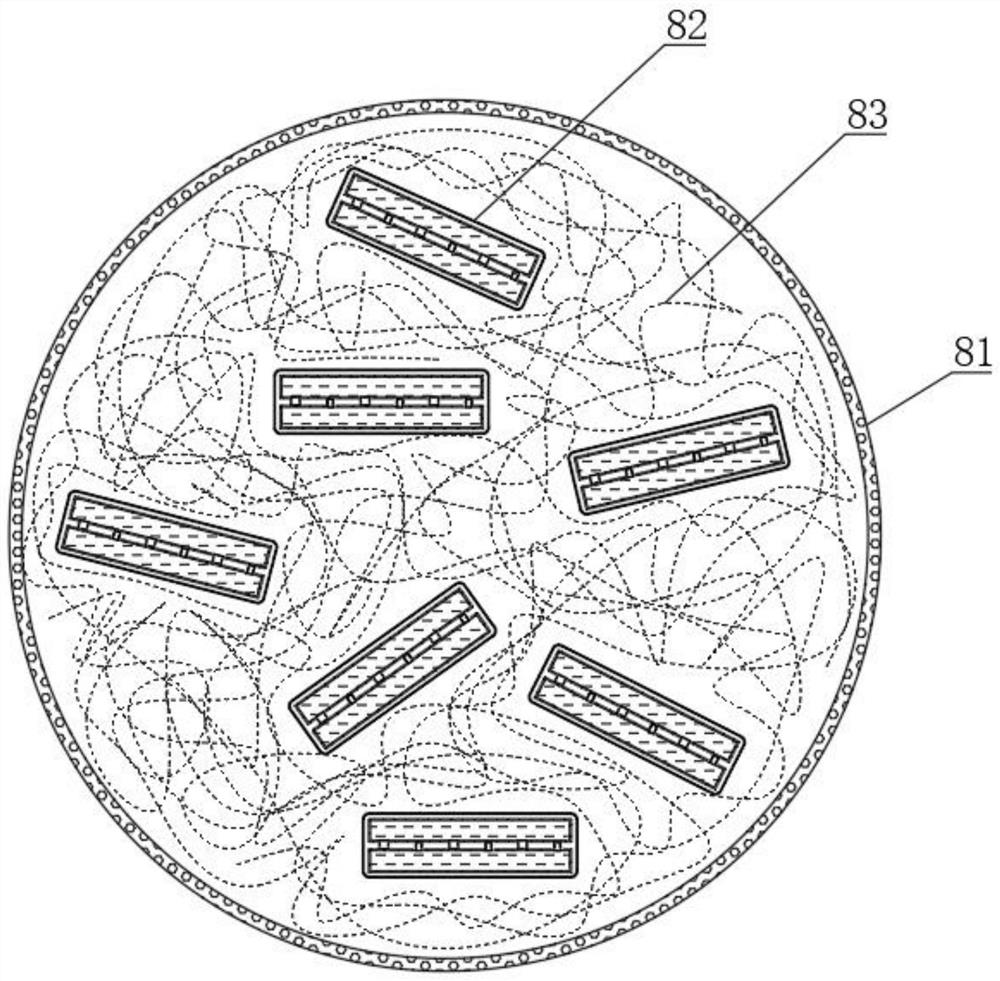

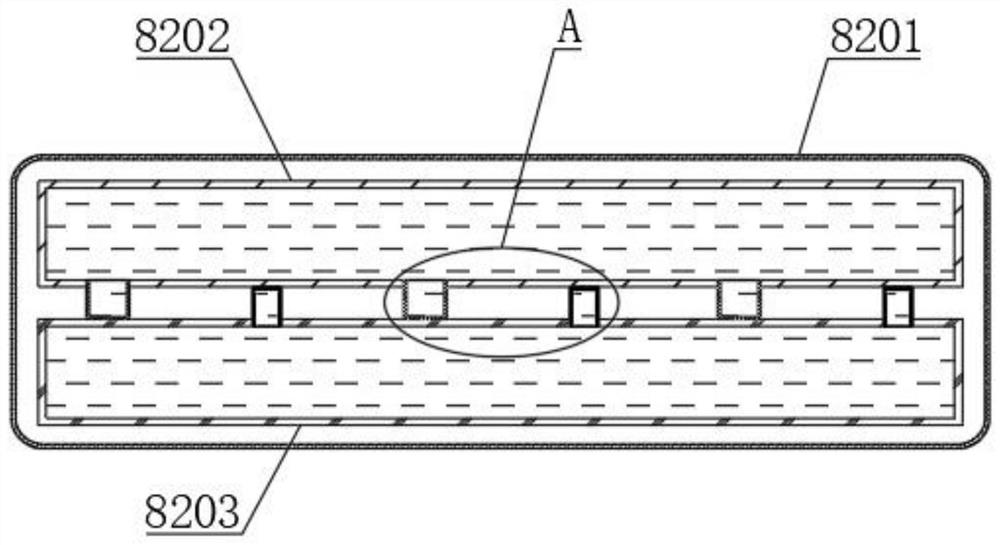

[0041] see figure 1 , a circulating refrigeration filter system for machine tool cutting coolant, including a coolant tank 1 installed inside the machine tool, the coolant tank 1 is used to hold the cutting coolant for cooling parts and processing tools, and the coolant tank 1 is fixed The infusion tube 2 is connected, and a refrigeration box 3 and a transition box 6 are installed inside the machine tool. The interior of the refrigeration box 3 is provided with a U-shaped network pipe 5, and the two ends of the U-shaped network pipe 5 respectively pass through a pair of side ends of the refrigeration box 3 and extend To the outside of the refrigeration box 3, and the U-shaped network pipe 5 is fixedly connected to the refrigeration box 3, and the outer end of the infusion pipe 2 is fixedly connected with the outlet pipe 4 and the introduction pipe 7 communicating with the infusion pipe 2, and the outlet pipe 4 is located in the cooling liquid tank 1 Between the outlet pipe 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com